Beer Brewery Restaurant Beer Brewing Equipment

JIANGXI UNITED CAN EQUIPMENT CO., LTD. / 2022-07-04

- Condition:New

- Customized:Customized

- Voltage:208V 3pH 60Hz , 380V 3pH 50Hz

- Composition:SUS304,SUS316,Red Copper

- Processing Material:Natural Ingredients

- Process:Ferment

=== Base Info ===

- Transport Package:to Be Confirmed

- Model NO.:HB

- Trademark:HiBeer

- Origin:China

- Production Capacity:40 Set,Sets Per Month 1000L Beer Brewrey Equipment

=== Description ===

Basic Info.

Model NO. HB Transport Package to Be Confirmed Trademark HiBeer Origin China Production Capacity 40 Set/Sets Per Month 1000L Beer Brewrey EquipmentProduct Description

100L 200L 300L 500L 1000L Beer Brewery Restaurant Beer Brewing Equipment

No matter you are a beginner or a skilled brewmaster in restaurant equipment, if you have passion for micro beer brewing, desire to have your own brewery, HiBeer will support you to realize your Dream for Brewing!

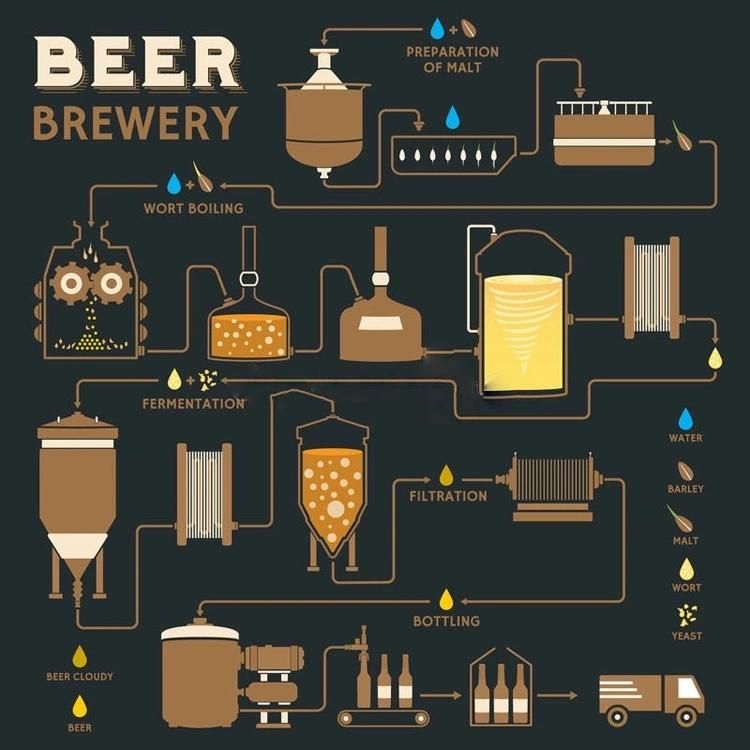

Beer brewery equipment suitable for:

-Pub/restaurant micro Brewery

-Small/mini Micro Brewery

-Recipe test& brewing beer teaching

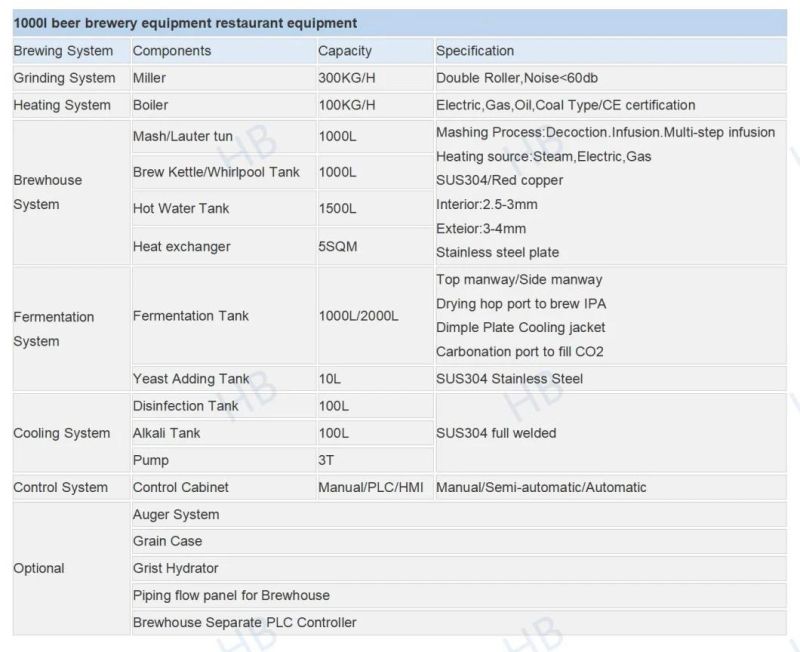

1000L Brewhouse

Mash system, it is the most important part of beer brewery equipment. It consist of mash tun,lauter tun, kettle, whirlpool tank. All of our equipments are made out of sus304.

A typical two-vessel:

Combination Mash Lauter Tuns are the first combination vessel in these smaller brewhouses line ups. This vessel should be sized to favor the Lauter operation, and have the mechanics for mixing mash and graining out.

Next inline is the combination of the Kettle and Whirlpool tanks. This combination vessel is designed and sized for being primarily a kettle, but is equipped with a tangential fitting for whirlpooling.

You May Like:

A three-vessel brewhouse is hybrid system that incorporates at least one combination vessel and two dedicated process vessels. For example, a medium sized brewery with a focus on heavily hopped beers might choose to go with a combination Mash Lauter Tun, a dedicated Kettle, and a dedicated Whirlpool. Whereas, someone focusing on lagers or feeding a distilling operation might go with a dedicated Mash Tun, dedicated Lauter Tun, and a combination Kettle/Whirlpool. Three-vessel systems don't have the same output and versatility as four-vessel systems, but they will still out perform a two-vessel system and provide increased efficiency.

A typical four-vessel brewhouse will include a Mash tun, Lauter Tun, Kettle and Whirlpool. Each of these tanks is dedicated to performing a single process, and is designed differently than similar vessel used for performing multiple processes.

1000L Fermentation System

Our fermenters can be individually temperature controlled through glycol jackets and are mostly equipped with accessories such as over-pressure and under pressure valve(PVRV), CIP arm, sanitary sample calve, manway, etc, The design of fermenters is based on our vast beer knowledge and especially the conical fermenter bottom and the fact that we combine fermentation and maturation in the same vessel is very important. When calculating your fermenting& lagering capacity and configuration, sufficient time for fermenting and lagering to produce quality beers must be taken into consideration.

Brewery Accessories

Every part of the 1000l beer brewery equipmnet is from world famous brand, (SIMENS PLC, Schneider/ABB/Omron low voltage electronic, Shanghai Huazheng boiler, COOLSOON chiller, Copeland compressor, suspension plate exchanger and so on), we can confirm the good quality.

Packaging & Delivery

Packaging & Delivery 1. the beer brewery equipment will be shipped by LCL/FCL ( 20GP/40GP/40HQ )

2. the 1000l beer brewery equipment will be packed with plastic film in fumigation free wooden case or fixed with iron frame

3. the beer brewing equipment is up to export standard, Suitable for delivery.

4. By bulk carrier or independent containers, the size and quantity rely on the configurations and capacity.

5. Customers' requirements of the packages are available, Please tell us in advance.

Our Service

1, Free consultation service before, during, and after sales

2, Project planning and design services

3, Free debugging instruction of equipment until everything is functional

4, Management of equipments' long distance shipping from seller's factory to named port or station by buyer

5, Training of equipment maintenance and operating personally

6, New production techniques

7, Provide 36 months complete warrantee for main parts and life-time maintenance service;The seller is responsible for the nature amage of the machinery in the warranty period except for man-made damage. All spare parts and wearing parts are attached with the machinery for free

All beer brewery equipment spare parts and wearing parts are attached with the machinery for free freely.

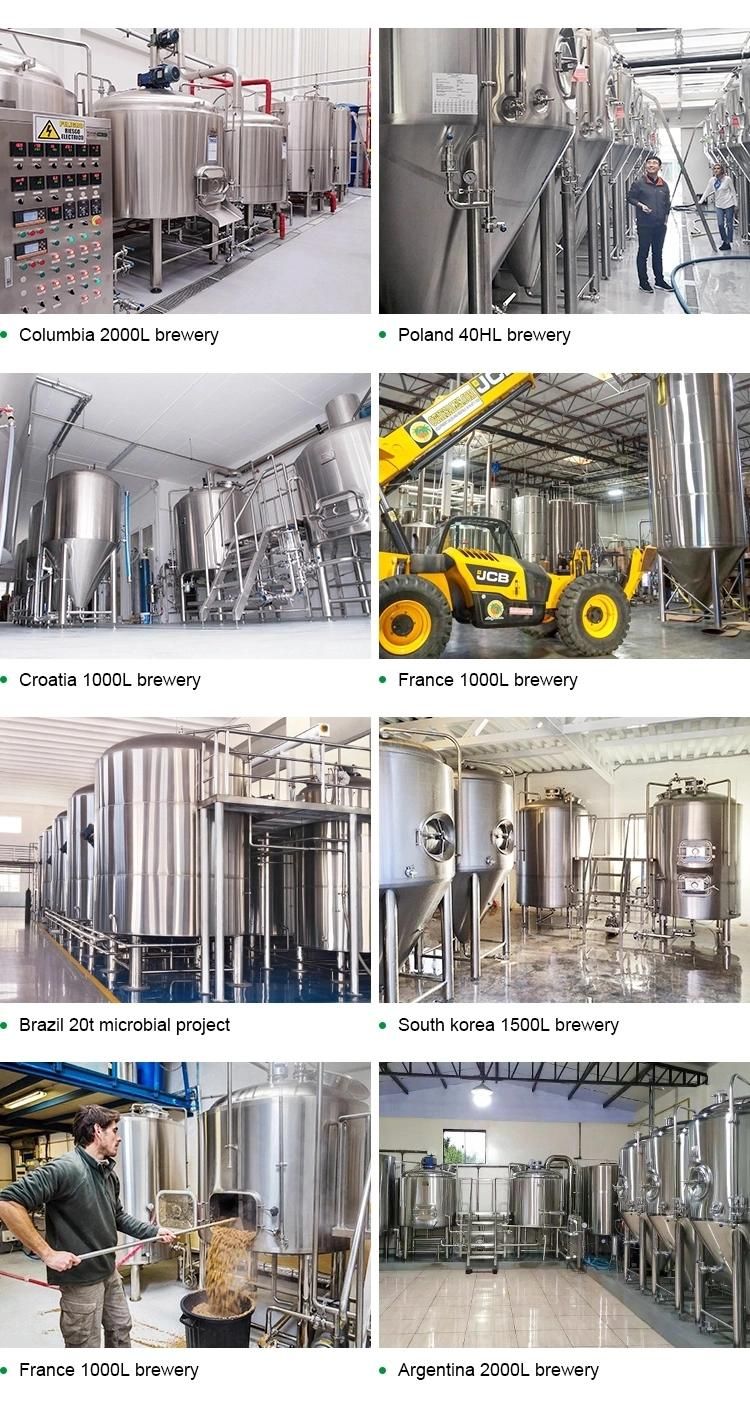

So far, we have exported the beer brewery equipment to many countries, such as Amercia, Canada, Poland, Portgual, Chile, Brazil, Spain, France, UK, Netherland, Czech Republic, Italy, Romania, Greece, India, Russia, Australia, South africa, South Korea and so on. In the meanwhile, there are many customers visited us to inspect the equipment quality and talked more about their project in our office/bar.

We welcome you come here to visit us, so we can talk more about your brewery project by face to face.

What Can we do for you?

New design: the company can design according to CE PED standards and ASME design codes

Localized after service: the company has set up three overseas branches located in the United States, the United Kingdom and Canada, as well as localized technology, sales and operation teams in Europe and the United States

New production: the company deploys a series of advanced production and testing equipment, modern production workshop of nearly 30,000 square meters, which organize production according to European and American technical and quality standards.

New Function: Network technology to achieve remote control.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23