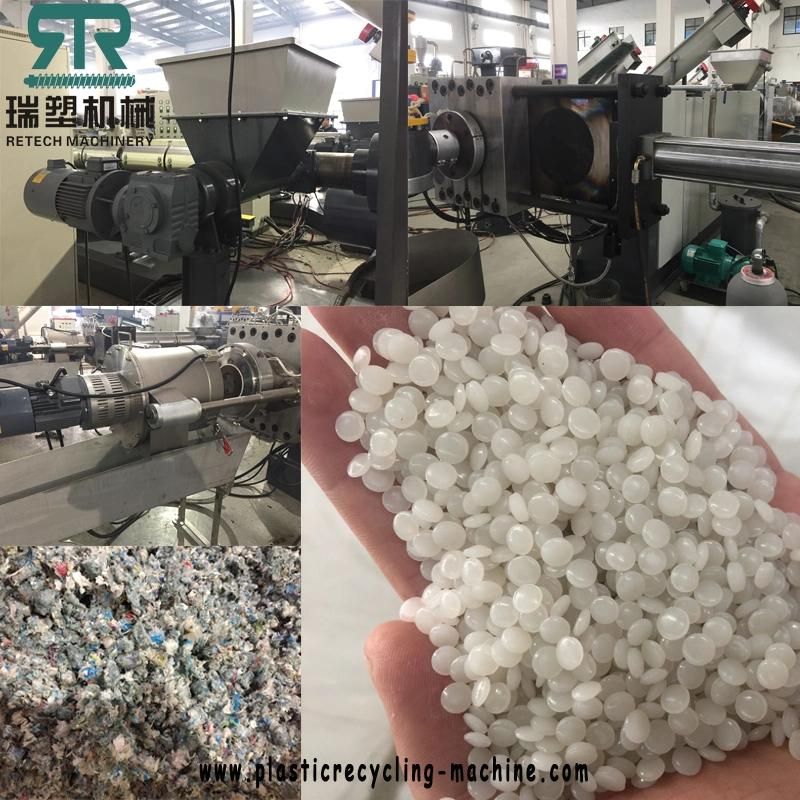

PVC PS PA Pet Bottle Recycling Line Pet Pelletizing Machine

Dongguan Yize Precision Cutting Tool Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. TSSJ100~200 THSJ65~220 TCSJ85~180 TCDJ85~180 Computerized Customized Certification ISO9001:2008, CE Color Could Be Customized Type of Extruder Deagassing Tyep After-Sale Service Engineers Available to Service Machinery Overseas Stage Doulbe or Single or Multi Feeder Type Force Feeder or Compactor Transport Package Wrap Film Specification TSSJ100~200 THSJ65~220 TCSJ85~180 TCDJ85~180 Trademark TopMachinery Origin China HS Code 8477201000 Production Capacity 50~600kg/HProduct Description

PVC PS PA PET bottle recycling line PET pelletizing machine

PVC PS PA Pet Bottle Recycling Line Pet Pelletizing Machine Main Features:

1. Feeding way of plastic pelletizing recycling plant: Special designed force feeder, side feeder and compactor can push the material into the extruder high efficiently. Guarantee getting good capacity of the machine

2. Gear reducer of plastic pelletizing recycling plant: The high torque, hard-surface gear reducer with water cooling circulation system ensures the line running steady, silent, and long life.

3. Barrel and screw of plastic pelletizing recycling plant: The special material (38CrMoA1A & double alloy) and hardness treatment of the screw and barrel make extruder to be good wear resistance.

4. Degassing of plastic pelletizing recycling plant: Special design for the venting can discharge the moisture and waste air efficiently which ensure the finally plastic granules are with smooth surface, no water, no bubble, and good quality.

5. Hydraulic filter of plastic pelletizing recycling plant: Double position hydraulic filter works swift and easy to operate. Copper ring prevents the material leakage.

6. Cutting way of plastic pelletizing recycling plant: Two type cutting way, the noodle type and water ring type makes the customer freely to choose.

7. Special designed die of plastic pelletizing recycling plant: All die holes size are special designed due to the material characters and our rich experience to make machines.

8. Cooling way of plastic pelletizing recycling plant: Most of the materials are cooled by water. Some like PVC are cooled by wind. e with smooth surface, no water, no bubble, and good quality.

9. Cutting way of plastic pelletizing recycling plant: pineapple cutter is for the noodle cutting way, and die face cutter for the water ring cutting way.

10. Package of the final products of plastic pelletizing recycling plant: Final products granules will be blowing into silo, which will be packaged by manual or packaging scale machine

11. Electric parts of plastic pelletizing recycling plant: Siemens, Schneider, Fuji, ABB, Mitsubishi, TECO all electric parts customized.

Single Screw PET Granulating Recycling Machine Line

| Model | Diameter of screw | Capacity |

| TSC-100 | Φ100mm | 100-150kg/h |

| TSC-120 | Φ120mm | 150-200kg/h |

| TSC-150 | Φ150mm | 200-300kg/h |

| TSC-180 | Φ180mm | 300-350kg/h |

Twin Screw Pet Pelletizing Recycling Machine Line

| Model | Diameter of screw | Capacity |

| TTC-75 | Φ75mm | 300-400kg/h |

| TTC-90 | Φ90mm | 400-500kg/h |

| TTC-95 | Φ95mm | 500-600kg/h |

360°services:

Customer requirements →Scheme designed →confirmed by customers →order fixed →manufacturing →trial running in our factory →confirmed by customers →shipped →engineer available overseas →whole life after sales services

Package and Loading:

Contact us:

RETECH machinery is an experienced and professional manufacturing for series plastic washing recycling machine/ plastic granulating recycling machine including ET bottle recycling machines, PE PP film recycling machines, plastic PE PP PS ABS PET PC PVC LD HD LLD BOPP granulating line, water treatment for the waste water from washing line, and auxiliary equipment for plastic recycling....

If you are interesting more details of our products, please contact with us no hesitation!

plasticmachine.en.made-in-china.com

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23