Cherry Jam Production Equipment /Cherry Paste Processing Plant

Nanjing Lipack Import and Export Co., Ltd. / 2022-07-05

- Type:Fruit & Vegetable Production Line

- Voltage:380V

- Power:Depending on The Capacity and Configutation

- Customized:Customized

- Material Capacity:1-65tons,H

- End-Products:Mano Juice, Mango Puree

=== Base Info ===

- Model NO.:shjump-MMNJ01

- End-Products Package:Aseptic Bag, Bottle, Tin Cans, Pouch, Pet, etc

- After-Sale Service:Engineers Available to Service Machine Overseas

- Certification:Ce, ISO9001

- Transport Package:Wrap Plastic Film to Keep and Stable Wooden Packag

- Specification:Stainless Steel 304,316

- Trademark:SHJUMP

- Origin:Shanghai of China

- Production Capacity:20

=== Description ===

Basic Info.

Model NO. shjump-MMNJ01 End-Products Package Aseptic Bag, Bottle, Tin Cans, Pouch, Pet, etc After-Sale Service Engineers Available to Service Machine Overseas Certification Ce, ISO9001 Transport Package Wrap Plastic Film to Keep and Stable Wooden Packag Specification Stainless Steel 304/316 Trademark SHJUMP Origin Shanghai of China Production Capacity 20Product Description

1. Full Automatic Canned Mango Processing Machinery description (

2. Our advantage

1.This project is the combination of domestic and foreign advanced technology to the production of fruits and design, and different seasons can produce different fruits.

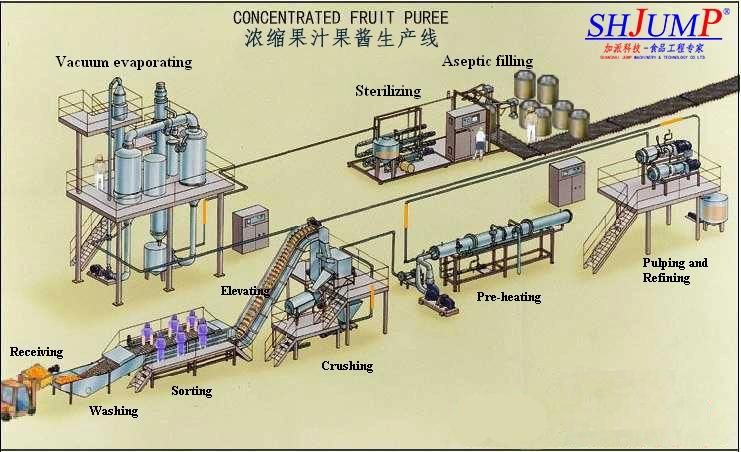

2. All the equipment in the system are made of stainless steel (directly contact with the raw material ) are the most advanced processing technology as the foundation of modernization. The whole process design and the connection of pipeline are arranged after engineers fine compute, and considering the retention of the original natural aromatic constituents of fruits and vegetables, the cooling ,heating processing and the transmission are finished in a short time and distance, effectively preventing flavor and substances losing in the thermal reaction ; and also reduce the oxidation under high temperature conditions reflect to bring quality damage. The whole production line from fruit crushing material, all in a closed environment, through crushing, water cooking separation, concentration, sterilization, filling and aseptic environment,

maximize the retention of the original flavor and nutritional ingredients.

3.The operation of the control part use the automatic control system, automatic fault alarm system, a full range of security mechanism, security equipment and personnel safety; all electric control system parts were derived from the international well-known brands, such as Siemens, Omron and so on.

4.The types of steam control in production line (extremely important, related to the quality of products) all come from world famous steam control system brand Spirax sarco ,easy control, high reliability, effectively ensuring the quality of different batches of the product pure and the balance.

5.The main equipment are from Shanghai JUMP Machinery & Technology Co., Ltd.to ensure the equipment reliability, controllable ; the accuracy of the parameters; stability and safety.

3. Our services

We can suggest customer the most suitable machine according to their formula and Raw material. "Design and development", "manufacturing", "installation and commissioning", "technical training" and "after sales service". We can introduce you supplier of raw material, bottles, labels etc. Welcome you to our production workshop to learn how our engineer produce. We could customize machines according to your real need, and we could send our engineer to your factory to install machines and train your worker of Operation and maintenance.

Packaging Details:

1. Stable wooden package protects machine from strike and damage.

2. Wound plastic film keeps machine out of damp and corrosion.

3. Fumigation-free package helps the smooth customs clearance.

4. The big size machine will be fixed in container without package.

Delivery Detail:

Date of delivery: in 90 working days after the date of the order.

Date of Installation and commissioning: in 30 working days after the factory is in place.

4. Factory site & Sales office

5. SHJUMP projects

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23