1000L Micro Turnkey Project Beer Brewery Brewing Equipment for Brewhouse Professional Beer ...

Hangzhou Panache Import and Export Co., Ltd. / 2022-07-05

- After-sales Service:Whole Life

- Warranty:3 Years

- Condition:New

- Customized:Customized

- Voltage:3 Phase, 380V 50Hz , 220V 60Hz

- Composition:Beer Brewery Equipment

=== Base Info ===

- Model NO.:CJ-1000

- Processing Material:Wheat, Malt, Barley

- Process:Ferment

- Polishing:Less Than 0.4 μm

- Dimension:Customized

- Power:15-72 Kw

- Insulation:50-100 Polyurethane

- Combination Method:Mash,Lauter Tun, Kettle,Whirlpool Tank

- Water Consumption:3.5m3,T

- Heating Way:Electric Heating,Steam Heating,Direct Fire Heating

- Control System:PLC

- Degree of Automation:Semi-Automatic,Fully Automatic

- Washing:360 Degree Spray Ball

- Manway:Top or Side

- Application:Restaurants, Bars, Hotels, Brewery

- out Size:Custom Made

- Certification:CE ISO UL

- Transport Package:Wooden Case or Steel Frame

- Specification:100L~3000L

- Trademark:CHENJI

- Origin:Jinan, China

- HS Code:8438400000

- Production Capacity:500 Sets Per Year

=== Description ===

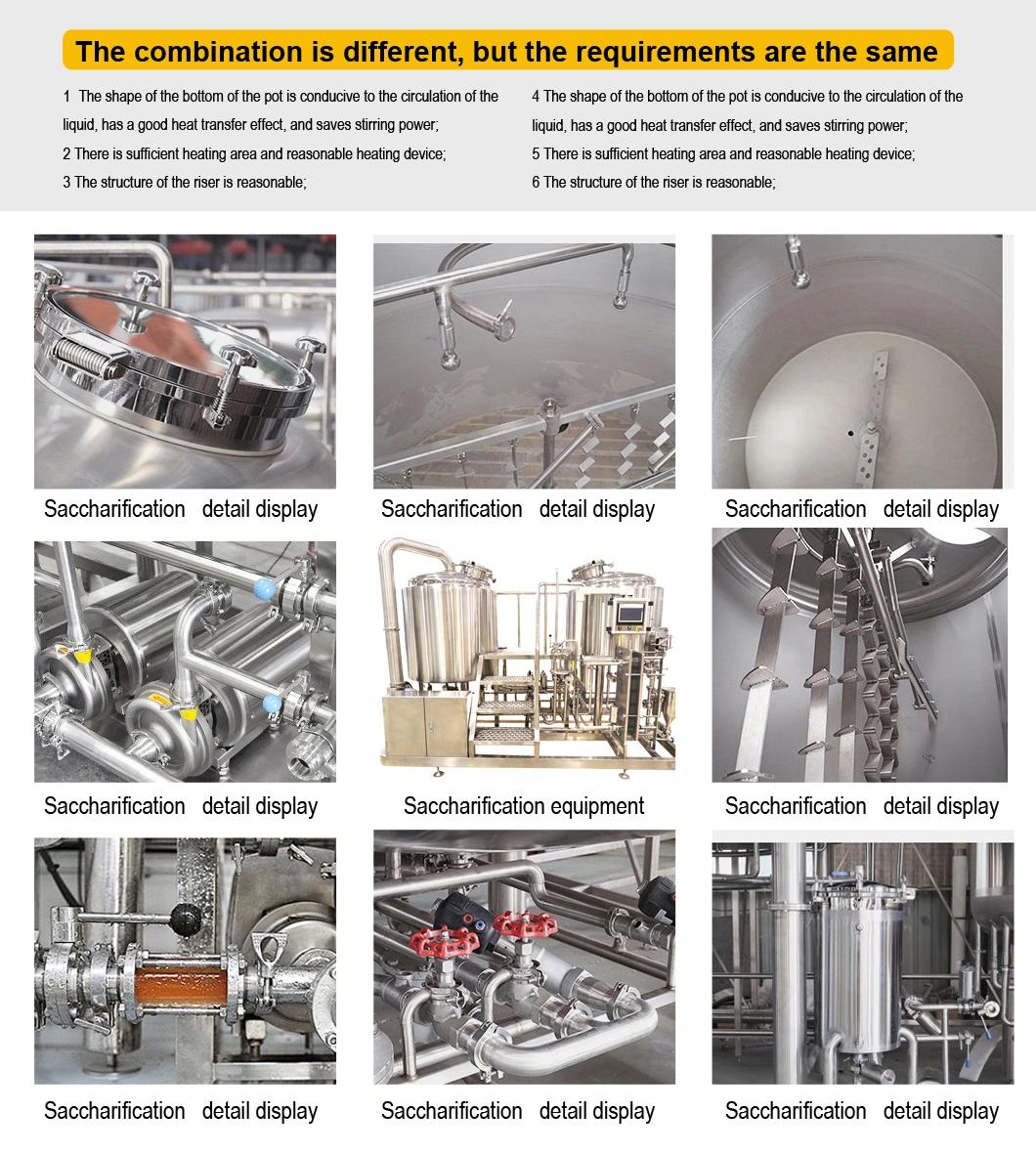

Milling V-wire false bottom

With lauter rakes, VFD control

Side spent grain manhole

Stainless steel top manhole

With tangent whirlpool inlet

Efficient centrifugal wort pump/hot liquor pump

With hops filter for trub collection

Stainless steel plate heat exchanger for wort cooling

Oxigenate with carbon stone

Sanitary stainless steel butterfly valves and pipeline connection

Stainless steel heavy duty supporting legs

Argon gas protection welding, well polishing

Electric heated: heating elements

Steam heated: steam jacket

Direct fire: firebox

Items for Optional:

-Agitator in kettle/whirlpool

-Hydrator

-Wort collector

-Grant

-Balance tank (sight glass type)

-Steam generator, electric/gas/diesel

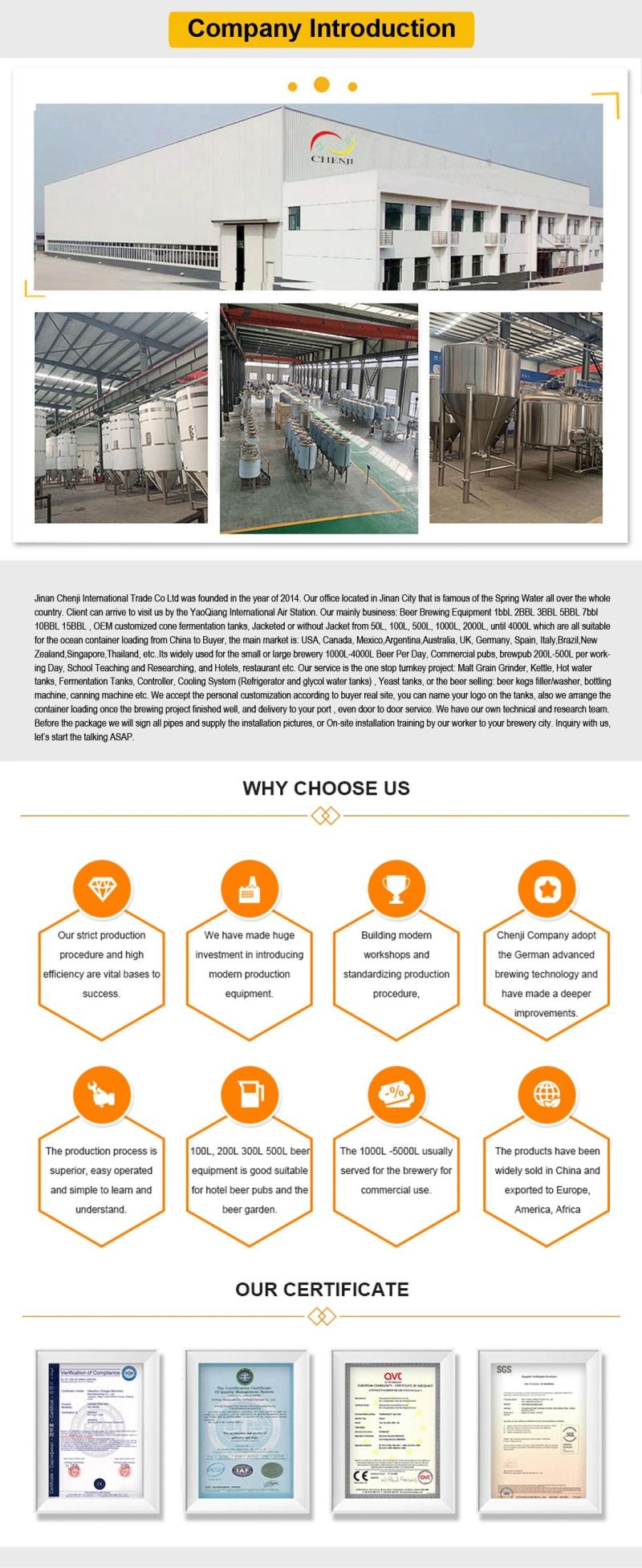

We provide customized solutions for your beer fermentation and storage. The unique tank design and the highest quality standards ensure consistent beer quality and flexible installation. The hygienic design allows for proper cleaning and guarantees product safety. Continuous quality control guarantees the best processing.

We provide customized solutions for your beer fermentation and storage. The unique tank design and the highest quality standards ensure consistent beer quality and flexible installation. The hygienic design allows for proper cleaning and guarantees product safety. Continuous quality control guarantees the best processing.

In addition to classic indoor and outdoor installations, our modular "cone in the box" system provides the best solution for combining indoor installation with cost-effective building expansion.

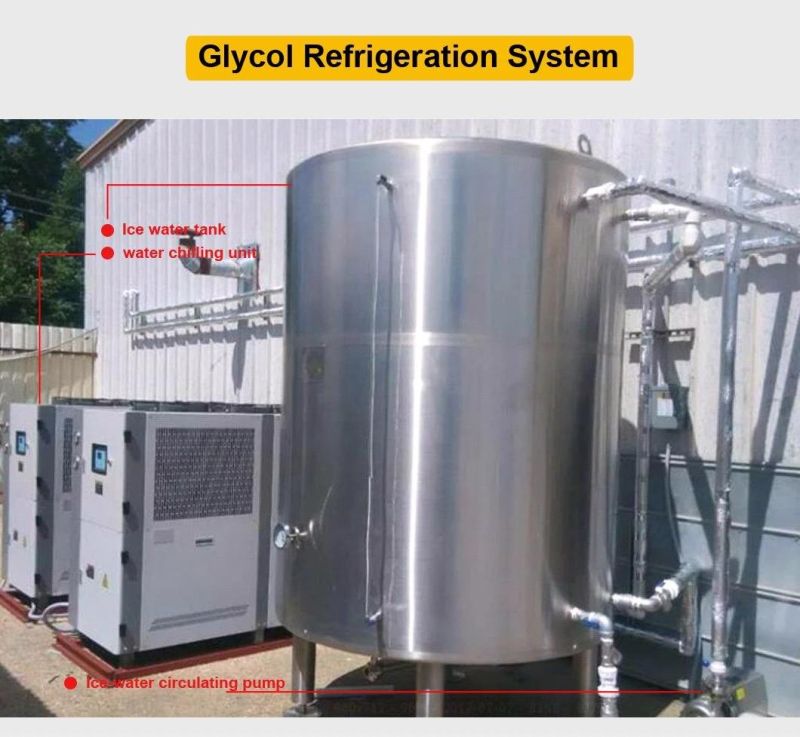

Ice water tanks, cold water tanks, stainless steel plate heat exchangers, refrigerators, refrigeration pipelines, pipe fittings and valves and control systems, of which the refrigeration unit is the core part, and the compressor unit is refrigerated with liquid ammonia, which are respectively used for tap water heat exchange and direct fermentation , Sake cans reduce the temperature of beer. The refrigerating machine adopts imported compressor, which is safe to operate and has a low failure rate, which solves the user's worries. The system pipelines are all made of sanitary and seamless steel pipe welding and fusion. Freon runs in the pipe to cool down, and high-quality polyurethane insulation pipes are used for pipelines. Thermal insulation effectively reduces heat loss.

The refrigeration system is used to cool down the saccharified wort and fermentation. The optimized design of the refrigeration system directly determines the lower energy loss in the operation of the equipment. The refrigerator we use is safe to operate and has low failure. The ice water tank is insulated with polyurethane, and the pipeline is insulated with polyethylene, which effectively reduces cold loss. The equipment cooling system is used to cool down the saccharification wort and fermentation, and is a major energy-consuming system that composes the beer equipment. The optimized configuration of the refrigeration system directly determines the lower capacity loss during equipment operation. CHENJI develops reliable CIP solutions to achieve the highest hygiene and quality requirements. Automatic monitoring of temperature, time and concentration ensures that your equipment is clean and sterile.

CHENJI develops reliable CIP solutions to achieve the highest hygiene and quality requirements. Automatic monitoring of temperature, time and concentration ensures that your equipment is clean and sterile. CHENJI develops reliable CIP solutions to achieve the highest hygiene and quality requirements. Automatic monitoring of temperature, time and concentration ensures that your equipment is clean and sterile.

CHENJI develops reliable CIP solutions to achieve the highest hygiene and quality requirements. Automatic monitoring of temperature, time and concentration ensures that your equipment is clean and sterile.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23