Corn Flakes Processing Line Machine

Ningbo DSW International Co., Ltd. / 2022-07-05

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Mild Processing

- Automatic Grade:Automatic

- Application:Candy, Chips

- Customized:Customized

=== Base Info ===

- Model NO.:SLG65-III

- Material:Stainless Steel

- Electric Parts:LG, FUJI, Omron etc

- Capacity:Capacity120-140kg,H, 200kg,H, 300-400kg,

- After-Sales Service Provided:Engineers Available to Service Machinery Overseas

- Warranty:One Year

- Product Name:Baked Corn Flakes Machine

- Motor:Siemens, ABB and China Brands

- Energy:Electricity, Oil Diesel, Gas, Steam

- Export Markets:Global

- Transport Package:Woodcase

- Trademark:Jinan Datong Machinery Company

- Origin:Jinan

- HS Code:84361000

- Production Capacity:100-150kg,H

=== Description ===

Basic Info.

Model NO. SLG65-III Material Stainless Steel Electric Parts LG, FUJI, Omron etc Capacity Capacity120-140kg/H, 200kg/H, 300-400kg/ After-Sales Service Provided Engineers Available to Service Machinery Overseas Warranty One Year Product Name Baked Corn Flakes Machine Motor Siemens, ABB and China Brands Energy Electricity, Oil Diesel, Gas, Steam Export Markets Global Transport Package Woodcase Trademark Jinan Datong Machinery Company Origin Jinan HS Code 84361000 Production Capacity 100-150kg/HProduct Description

Full-automatic Baked corn flakes machine1.Description of Baked corn flakes machine:

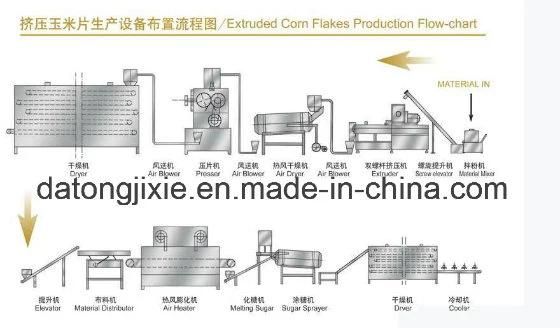

Baked corn flakes machine takes corn flour, rice flour, what flour and other grains as raw materials. After mixing, extruding, shaping, drying, sugar spraying, and cooling, you can get sweet and crispy corn flakes, breakfast cereals etc. The final products contain abundant compound carbohydrates and dietary fiber. It's rich of microelement such as vitamin and mineral. It can be taken directly after being mixed into coffee, milk, yoghourt or other drinks. This production line is multifunctional and highly automatic, easy to operate. You can produce various shapes of cereals and snacks by changing different moulds, such as: ring, ball, flake, star, moon, letter and so on.

2.Baked corn flakes machine Configuration:

1). Raw material mixer.

2). Screw Conveyor

3). Extruder machine

4). Air Conveyor

5). Dryer machine

6). Flavoring Machine

7) Dryer machine

3.Technical Parameters of Baked corn flakes machine

| Model Parameter | SLG 65-III | SLG 70-II | SLG 85-II |

| Installed power | 140kw | 160kw | 190kw |

| Output | 120-150kg/h | 200kg/h | 300-400kg/h |

| Dimension | 39*2*2.5m | 41*2*2.5m | 43*2*2.5m |

4.The Samples of Baked corn flakes machine

The Baked corn flakes machine can take corn, rice, wheat, oat, rye and other grains as materials to produce extruded snacks, with crispy taste.

5.The Baked corn flakes machine Packaging and Shipping

Packing: inside plastic bag, outside wooden case for Baked corn flakes machine (Based on the customers' need adopt the wooden case or wooden pellets, etc.)

Transportation: shipping, train, express or what the client need

6.The service of the Baked corn flakes machine:

1). We can provide factory layout according to customer's factory size in advance.

2). When we received your deposit of this order, we will ask our engineers to prepare to apply the visa, when the processing line arrived your country, and we will send two engineers to go and help you to install the line, teach your worker(3-4 workers) how to operate the line, until your worker know the processing line well.

3). Our engineers has responsibility to teach your worker how to clean the extruder, how to change the screw, how to change barrel etc. and we have responsibility to provide technology support with you forever.

4) Our engineers can provide basic formula for producing the food. and help customer to produce good quality food according customer's detailed formula.

5). We provide the spare parts will at preferential price for an extended long time.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23