Biscuit Depositor Rotary Mould Machine Wire Cut Biscuit Production Line

Xiamen ZA Technology Co., Ltd. / 2022-07-05

- Power Source:Electric

- Automatic Grade:Automatic

- Application:Biscuit

- Customized:Customized

- Power:1.5 Kw

- Ext Dim:1600*950*1380

=== Base Info ===

- Model NO.:NKC-400B

- Weight:450kg

- Tray Size:400*600mm

- Memory System:12 Memory

- Body:Stainless Steel 304

- Capacity:25 Lines,Min, 6PCS,Line

- Control System:Mitsubishi PLC Control

- Transport Package:Wooden Case

- Specification:400

- Trademark:Nicko

- Origin:Guangzhou China

- HS Code:8514300090

- Production Capacity:20

=== Description ===

Basic Info.

Model NO. NKC-400B Weight 450kg Tray Size 400*600mm Memory System 12 Memory Body Stainless Steel 304 Capacity 25 Lines/Min, 6PCS/Line Control System Mitsubishi PLC Control Transport Package Wooden Case Specification 400 Trademark Nicko Origin Guangzhou China HS Code 8514300090 Production Capacity 20Product Description

Product Description

Cookies Depositor/ Cake Filling Machine for baking cake machine

1. Bakery shop

2. Food factory

3. Super market, ect

4. Wide baking range: Pie, moomcake, bread, taost, hamburger, cake, biscuit, meat, ect

This machine is fitted with high speed PLC 7" Coloured T.F.T. touch screen which means lot of space (Lot of Recipes Storage Capacity) in short Now production of cookies is on your finger tips.

Length of the tray : As per customer's choice.

Available in 4 to 10 Nozzles suitable 10" to 26" tray width

Two wire cut dies & one depositor die included with complete set of nozzle.

Total Power requirement : 3 HP

Machine is preprogrammed with up to 15 different languages.

Stainless steel construction:Designed for durability, ease of cleaning and overall sanitation.

Store multiple production recipes for quick product recall and streamlined production processes when changing between products.

Unmatched Flexibility :

This machine operates on independent motors for all the functions, which give you the flexibility to make different kinds of products.

Nozzle rotation is powered by geard motors & A.C. Drive, therefore it is more flexible, you can choose the speed & time to give different shapes and designing for your cookies.

Good Positioning Control :

The tray movement is powered by a Servo Motor which result in adequate positioning control. Now you can adjust the distance between rows in mm which means more accurate & more efficient. You can utilize full space of tray/oven by adjusting no. of rows as per your requirement.

Up down movement is controlled by servo motor for more accuracy. You can adjust the different levels of height according to your different variety of cookies.

Built in encoder for dough feed rollers, which means more accuracy in ramage of cookies.

Similarly, this machine is filled with the most advance features in cookie production technology and what your customer want

Other salient features of this machine are:

Nozzle rotation is powered by a multy speed geared motor.

Up and down movement of the table is powered by a geared servo motor with braking unit.

Wire cut frame is powered by a geared motor.

Table height adjustment is fully automatic.

Multi layered & conical shaped cookies.

Special extra attachment i.e. Roller head for Muffins.

Tip control mechanics

Hole in center of cookies for depositing filling jam etc.

Servo drives controls for high speed and accuracy.

Powered With The Best :

World-class products have been used in the machine to deliver performance of the highest level. Spare parts and equipment used for the machine are provided by the best in the industry.

Geared motors form Bonfiglioli or Rotomotiv.

Servo motor from Teco Servo

Proximity switches from Omron.

PLC form Mitsubishi.

Touch screen 7" colored by delta.

| Mode | NKC-400B |

| Vol | single phase (220V) |

| Power | 2.0KW |

| Capacity | 40~80kg/hr, 25 lines/min ,6pcs/line |

| Ext Dim | 800*850*1350mm |

| Machine Weight | around 280kg |

| Control system | Mitsubishi PLC control |

| Material | SS304 |

| Automatic Grade | Automatic |

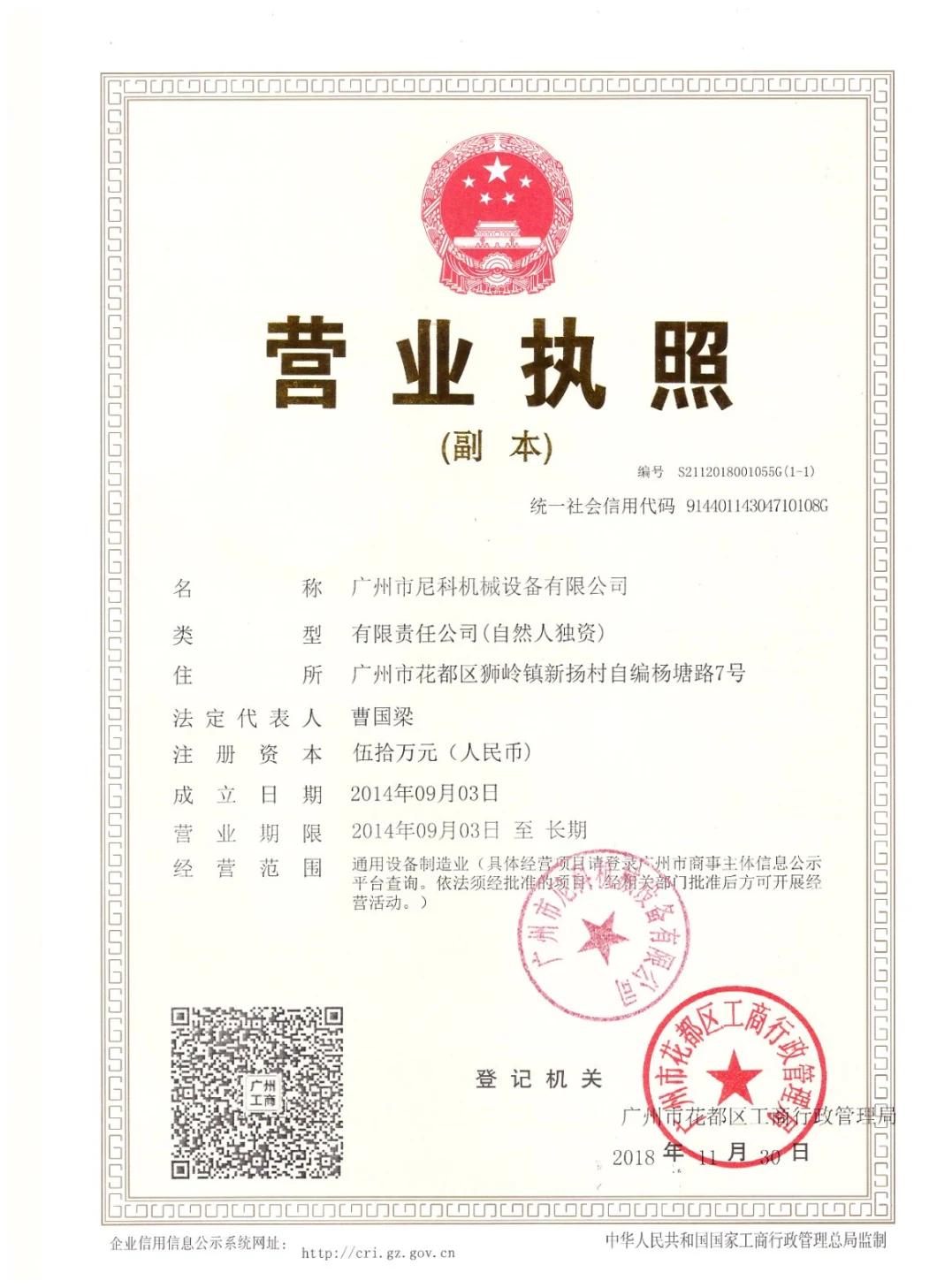

As one of the key food machine enterprises in Guangzhou, China, Guangzhou Nicko Machinery Co.,Ltd is specializes in the manufacture and export of food machine, kitchen equipment, bakery equipment, catering accessories and home appliances, ect.

With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in food processing industry and other industries. We are duly quality tested on the basis of their function, durability, efficiency and accuracy. These products are fabricated by using high grade quality raw materials and components that are sourced from the most trusted manufacture of the market. Our products are widely appreciated for their easy installation and help in many bakery applications.

FAQ

1. Why Choose us?

A: Our team have more than 10 yesrs experience , we are professioanl for the bakery equipment and export business. And we are know what the customer needs, we can supply the good quality products and competitive price to you.

2. What Methods of Payment Are Acceptable?

1) Telegraphic transfer(T/T). If you order is standard machine, just need to T/T 30% as deposit before production, then 70% T/T balance before shipment.

2) Western Union

3) L/C: 100% L/C Irrevocable at sight

4) Paypal

3.How about the delivery date?

Some of the products are in stock at our warehourse, generally we need 3-5days to change the plugs and prepare the pakage before the delivery. Refer to the Non-stock products, the lead time is approximated 30 working days depond on your requirement on the products.

How to contact with us?

Guangzhou Nicko Machinery Co.,Ltd

Guangzhou Nicko Machinery Co.,Ltd

Bestbake Food Machinery Co.,Limited

OfficeAdd: No.626 Meili Business Building Huadu District Guangzhou, Guangdong, P.R.China.

Factory Add:Dafeng Industrial Estate,Heyu village Huashan Town, Huadu District, Guangzhou,Guangdong, P.R. China Post Code:510000

Cell Phone:+86 -(0)13660858881 15915893856

Tel: 0086-20-83888339 Fax:0086-20-83888339

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23