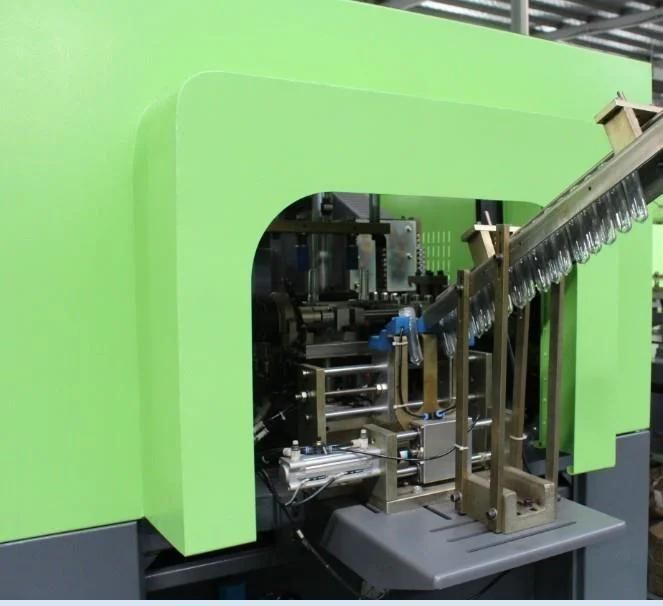

Automatic Pet Bottle Blow Molding Machine

Qingdao Landpower Machinery Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Model

Theoretical Output(b/h)

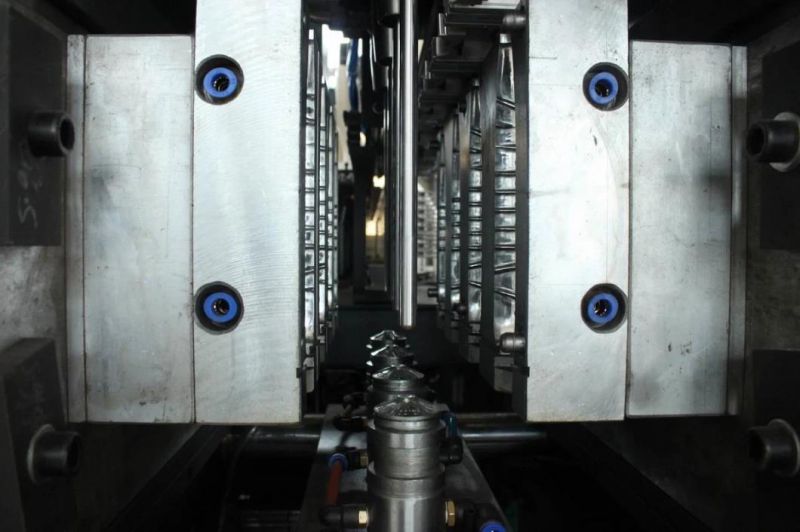

Clamping System

Cavities

Clamping Unit(Kg)

Mold Stroke(mm)

Stretch Stroke(mm)

Bottom Stroke(mm)

Cavity Pitch(mm)

Heating Pitch(mm)

Number of Holders(pcs)

Container

Max. Container Volume(L)

Max. Neck Diameter(mm)

Max. Preform Height(mm)

Max. Container Diameter(mm)

Max. Container Height(mm)

Electrical System

Heating Oven

Box × Channel

Number of Lamp(pcs)

Heating Power(kw)

Installed Power(kw)

Voltage(V)

Air System

Blowing Pressure(Mpa)

High Pressure Air Consuming(L/min)

Chiller System

Temperature(c)

Pressure(Mpa)

Flow Rate(L/min)

Heating Power(HP)

Machine

Machine Dimension(mm)

Weight(kg)

Packaging & Shipping

Wooden Package Standard Export Request

FAQ

1) Can your factory provide the whole plant from A to Z?

A: Yes, we can provide the complete plant, from bottling making plant, water purification plant, to filling packing plant.

2) Are all machinery your factory made?

A: Our factory make the water purification and filling packing plants. We do not make the bottle making machinery,

we have good quality bottle making machinery partner, and we provide to customer same long warranty time and good after service.

3) How can I know the machinery quality before I order?

A: Frist, we will invite you visiting our factory to check the machines quality, and show the machines running for you in our factory.

4)What certificates you can provide?

A: Our factory provide the CE, SGS, ISO, and accroding to some countries, we also can provide the Pvoc, Coc, Soncap...ect

5)Can your factory make the bottle drawing, workshop layout, and labels for us?

A: We can help customers design their own bottle shape, workshop layout and label drawings, these jobs are free charge.

(Workshop need customer to provide the size of factory)

6)Installation and Training Time

A: We have professional engineer for oversea installaion and training, they can speak English, and have much experience oversea work.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23