Corn Flakes Production Line for Breakfast Cereals, Snacks, Corn Flakes

Henan Techuang Biotechnology Co., Ltd. / 2022-07-04

- After-sales Service:Overseas Service

- Warranty:One Year

- Certification:CE, ISO9001, BV

- Power Source:Electric

- Process:Corn Flakes Production Line

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:LY65 70 75 80 90 110

- Application:Chips, Corn Flakes Production Line

- Customized:Customized

- Raw Materials:Wheat Flour, Corn Flour, Rice Flour etc

- Capacity:120-150kg,H 200-300kg,H 400-500kg,H

- Motors:Customized

- Electric Parts:ABB, Delixi, Schnider

- Inverters:Delta Ls ABB

- Products:Corn Flakes, Cereals, Snacks, Chips etc

- Materails:Stainless Steel

- Transport Package:Suitable for Ocean Shipment

- Trademark:LUERYA

- Origin:Shandong China

- HS Code:84388000

- Production Capacity:30 Sets Per Month

=== Description ===

Basic Info.

Model NO. LY65 70 75 80 90 110 Application Chips, Corn Flakes Production Line Customized Customized Raw Materials Wheat Flour, Corn Flour, Rice Flour etc Capacity 120-150kg/H 200-300kg/H 400-500kg/H Motors Customized Electric Parts ABB, Delixi, Schnider Inverters Delta Ls ABB Products Corn Flakes, Cereals, Snacks, Chips etc Materails Stainless Steel Transport Package Suitable for Ocean Shipment Trademark LUERYA Origin Shandong China HS Code 84388000 Production Capacity 30 Sets Per MonthProduct Description

Automatic Corn flakes Production Line For corn flakes, breakfast cereals, snacks made in chinaCorn flakes production line can produce corn flakes, which is one kind of nutritional convenient food which is produced by this process line, using corn flour as basic material, with different shapes. One outstanding characteristic of the corn flakes is that it contains abundant compound carbohydrates and dietary fiber, such as vitamin and mineral, and also can be added with cocoa and sugar, like honey and maltose. It can be eat directly after mixed into coffee, milk, Yogurt functional drink. Also can eat it as sweet crispy snack.

As the professional of automatic corn flake plant manufacturer,our corn flakes processing line design good manufacturing process. Corn flakes manufacturing plant can take the corn flour, wheat flour, rice flour and water and others to produce the corn flakes for sale.

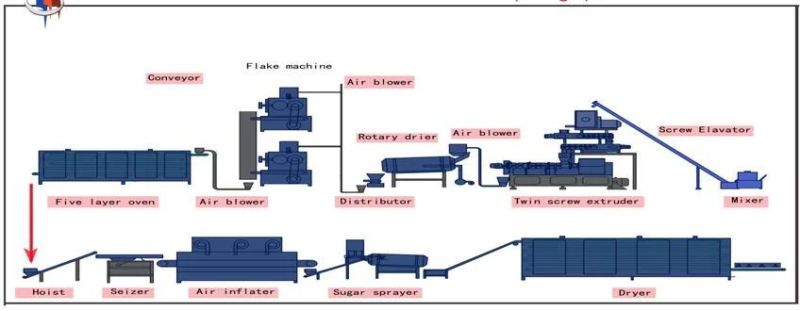

CORN FLAKE PRODUTION LINE PROCESSING DESIGN

Powder Mixer → Screw Conveyor → Twin Screw Extruder → Cooling Conveyor →Pre- Dryer → Air Conveyor → Flakes Machine→ Air Conveyor → Five-Layer Dryer → Hoist → Vibration Feeder → High Temperature Expander Machine → Sugar Melt → Sugar Spray System → 5-Layer Continuous Dryer Including Lifting And Cooling Section → (Packing Machine)

WHAT TYPE CORN FLAKE MAKING PLANT MACHINE WE CAN MANUFACTURING?

WHAT IS OUR ADVANTAGE OF THE AUTOMATIC CORN FLAKES PROCESSING MACHINE

- Adopting turbine and worm to adjust the gap of pressure roller, the adjustment effect is accurate and balanced

- The alloy coating on the surface of the pressure roller has high hardness and greatly improves the service life

- Equipped with an adjustable scraper to prevent the product from sticking to the pressure roller

- Equipped with pressure roller oil injection system to prevent the product from sticking to the pressure roller

- The tablet press can be supplied with cold water and has water-cooled pipes to prevent the press roller from overheating and affect product characteristics

- The high-temperature oven (it can be called a through-type oven) has an openable and closeable structure for the inlet and outlet guards to facilitate maintenance and cleaning

- The box body adopts double-layer aluminum silicate insulation board.

- The pipeline adopts aluminum silicate insulation layer.

- 6 groups of hot air blowers blow high-temperature hot air from the upper and lower parts of the material to the material, and the baking is even

- Each group of hot air blowers have independent air outlet ducts and return air ducts, with higher thermal efficiency

Corn Flake Plant Machine can make corn flakes, and also can make other grain flakes, and breakfast cereals.

Features:

1) Different types, flexible configuration, wide range of raw material etc.

2)Mutifuctional Can do variety shapes snack , ball, tube, stick, ring, star, wheel, flower and heart shape by adjusting the mould in the filling snack extruder production line machine .

3)Snack Raw material

Corn, rice, wheat, oat, grain flour etc. as coating,

Cream, chocolate, fruit paste, date paste, jelly etc. as filling.

4) Voltage: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

5)Production Capacity:120-150Kg/h,200-300Kg/h,400-500Kg/h

Welcome to visit our factory!

Shandong Luerya Machinery Manufacturing Co., Ltd. is located in the beautiful city(Jinan City)in Shandong Province China. Our company is a professional food extruder machine manufacture with many years' experience.

Our company offers variety of products which can meet your variety demands. We always try our best to satisfy potential needs of our customers. Our company is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with irresistible force.

With the development of our company, our products have been exported to more than eighty countries, such as the United States, Poland, Canada, Mexico, Brazil and so on.

In the unremitting efforts of all staff, we hope that our products and services can help you achieve personal career aim, we would like to use our sincerely and enthusiasm to become your long-term partner and intimate friend since our first touching.

Welcome to visit our factory!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23