Pert Pipe Rewinding Extrusion Machinery Process

Tongcheng Hongye Industrial Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

1000 Detailed Images 1.Single screw extruder (with automatic feeding system)1.Motor brand: Siemens 2. Inverter: ABB/Delta 3.Contactor: Siemens 4. Heating method: Ceramic or cast aluminum 5.Screw and barrel: 38CrMoAlA.6.Extruder model: SJ45/SJ55/SJ65/SJ75/SJ90/SJ100/SJ120/ SJ150

2.Mold1.Material: 3GR17 2.Diameter: Customized3.Pipe diameter:16-1200mm4.Pipe pressure grade:0.6MPa,0.8MPa,1.0MPa,1.25MPa,1.6MPaSDR26,SDR21,SDR17,SDR13.6,SDR11, etc.

3.Calibrating and cooling tank1.Raw material: #340 stainless steel2.Pipe diameter:16-1200mm3.Spray cooling:ABS nozzle4.Vaccum pump , Water pump :Simens brand

4.Haul-off machine1.Model:belt type/ two claws /three claws/four claws/six claws/eight claws.2.Servo motor support3. Diameter :16-1200mm4.Counter meter 5.Cutting machine1.Cutting method: chipless / planet cutting2.Pipe range:16-1200mm

5.Cutting machine1.Cutting method: chipless / planet cutting2.Pipe range:16-1200mm

6. Stacker1. Raw material :stailess steel2. Lenght:6m /12 m

Features HDPE pipes:1. Size: 16mm to 1800mm2, Thickness: 2 3-162mm

3. Pressure Rating: 0.6mpa, 0. 8mpa, 1. 0mpa, 1.25mpa, 1.6,2.0mpa

4. Color: black, black with blue stripes, other colors available on request

5. Connection: socket fusion joint, butt fusion joint, electro fusion joint, flanged joint

You just tell me what machine you want,let us do the rest work:

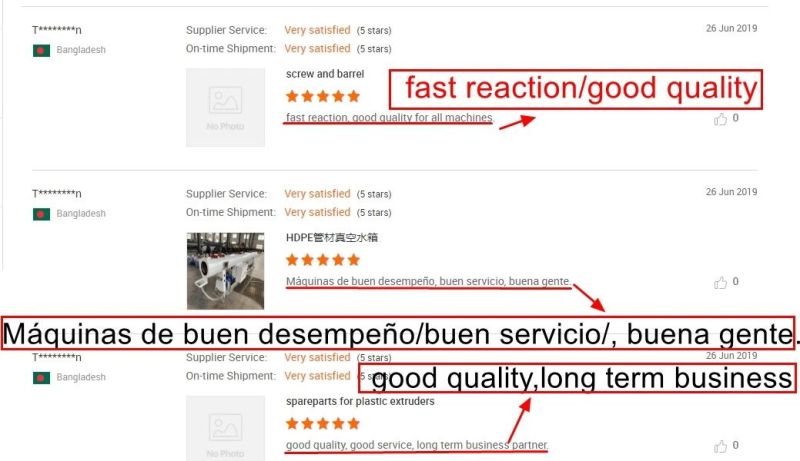

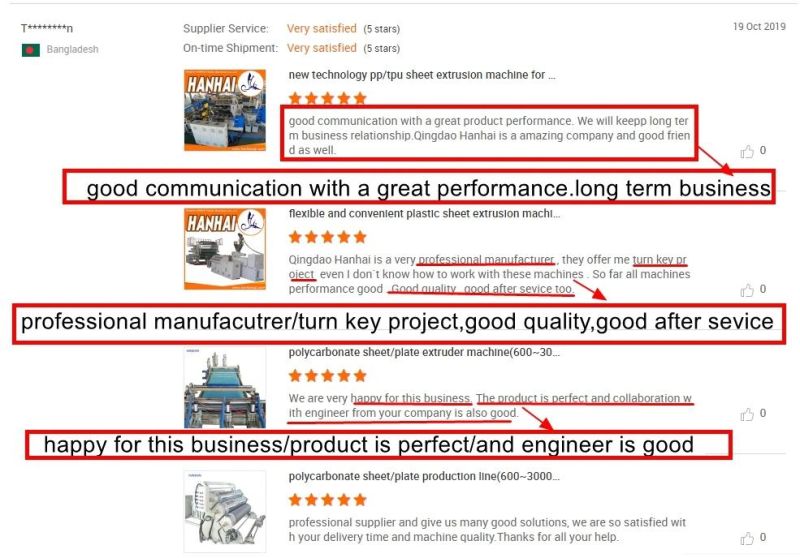

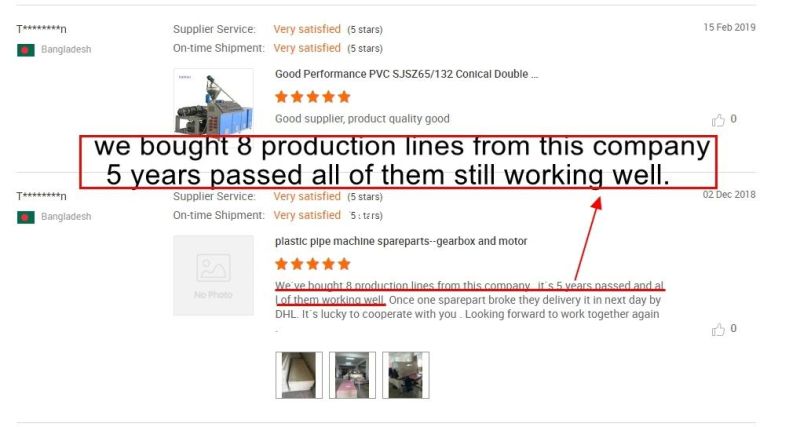

1. Design and manufacture suitble machine for you.2. Before delivery, we will test the machine until you are completely satisfied. (You can come to our factory to inspect the running production line.)3. Delivery.4. We will provide after-sales service: (1) Field installation and commissioning; (2) Field training your workers; (3) Field maintenance and repair service ;(4) Free Spare Parts ; (5) Video/Online technical support. Customer Comments

FAQ

FAQ1.Are you manufacturer or trading company? We are manufacturer.

2.Why choose us? We have 20 years experience for producing machine.We can arrange for you to visit our local customer's factory.

3.Delivery time:

30 days.

4.Payment terms: 30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C(at sight).

5.After-sales service: Free Spare Parts ;

Field installation, commissioning and training ;

Field maintenance and repair service ; Video/Online technical support.

6.Warranty: 1 year.

You just tell me what machine you want,let us do the rest work:

1. Design and manufacture suitble machine for you.2. Before delivery, we will test the machine until you are completely satisfied. (You can come to our factory to inspect the running production line.)

3. Delivery.

4. We will provide after-sales service:

(1) Field installation and commissioning;

(2) Field training your workers; (3) Field maintenance and repair service ;

(4) Free Spare Parts ;

(5) Video/Online technical support.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23