Straight Blade Grinder Machine 1400rpm Automatically Sharpen with CE

Guangzhou Ouster Hydraulic Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Factory price Crusher knife automatic straight blade grinding sharpener grinder machine

It is suitable for all kinds of long and straight knives used in plastics, printing, paper making, forestry, cutting tool machinery, food and other industries. Can be used for grinding, cutting edge, polishing edge; grinding straightness≤0.01mm/m

Knife sharpener is suitable for blades such as crusher blades, paper cutting blades, woodworking planer blades, plastic machine blades, medicine cutters and other blades.

Available with grinding lengths ranging from 1500 mm to 3100 mm, or longer for special grinding purposes. Blade grinding machine features a heavy-duty reinforced machine base which gives the maximum stability. PLC controls the carriage movement during the various stages of the working cycle.

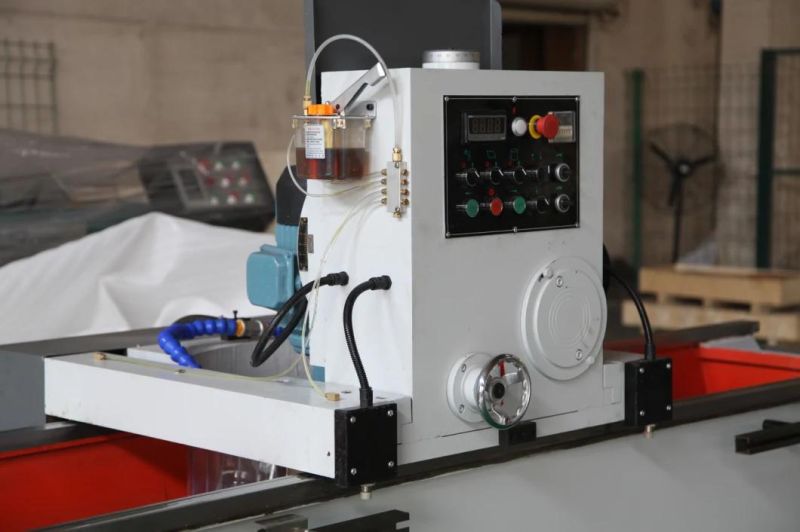

Machine Technical ParameterOperation Panel

Operation interface is simple and clear. The blades will be placed in the machine automatically. (Automatic operation or manual operation can be free switched)

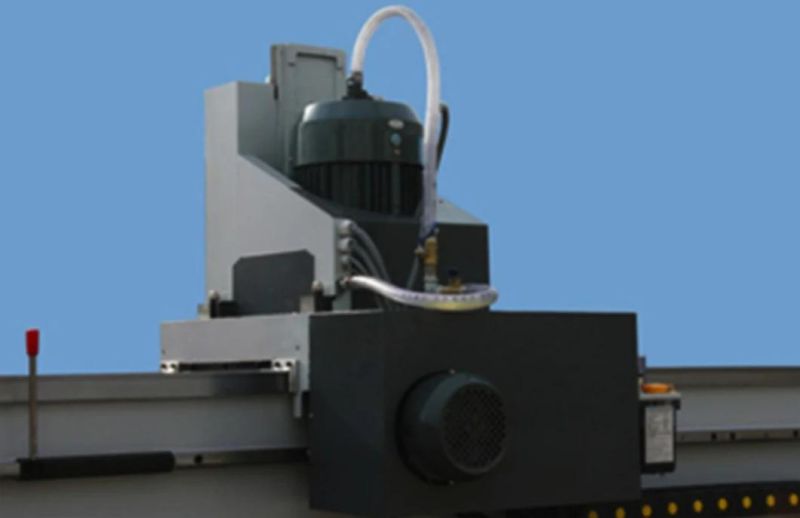

Grinding Motor

Grinding Motor

Adopt specialized grinding motor which is good accuracy, high stability. The grinding motor is equipped with quick change wheel device, convient for loading and unloading

Electro Magnetic Chuck

Strong copper coils magnetic chuck, for presetting the blades

FAQ

Q: What kind of Blade material can be sharpen by your machine?

A: D2, SKD-11, 9CrSi etc.

Q: What's the rotating speed?

A: 1400rpm

Q: What's stroke of your blade sharpener?

A: We have 700mm and 1500mm

Q: How long it will take to sharp one blade?

A: Normally 3-5mins. Depends on the blades

Q: How long it needs to change the grinding wheel?

A: Normally 2 months or about 130 pcs of blades

Q: Do you have CE certificate?

A: Yes, we have CE and ISO 9000 Certificate

Q: What's the delivery time after we paid the deposit?

A: 25working days

Q: What's the payment terms?

A: T/T. 30% as deposit , 70% should be paid before delivery after inspections Machine Photos How to Ensure the Quality √ In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

How to Ensure the Quality √ In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

√ Each component before assembly needs strictly control by inspecting personnel.

√ Each assembly is in charged by a master who has working experience for more than 20 years

√ After all the equipment are completed, we will connect all the machines and run the full production line to ensure the stable running

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23