Automatic Muesli Bar Making Machine Cereal Protein Bar Production Line

Shandong Longxing Plastic Film Technology Co., Ltd. / 2022-07-05

- After-sales Service:12 Months

- Warranty:12 Months

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

=== Base Info ===

- Customized:Customized

- Material:Stainless Steel,Carbon Steel

- Main Machine:Twin Screw Extruder

- Function:Fully Automatic

- Capacity:100-150g,H 200-250kg,H 300-500kg,H 300-500kg,H 800

- Installation:Engineer Guide

- Transport Package:Film&Wooden Box Packing

- Specification:2.5*1.2*1.5m

- Trademark:Donghe

- Origin:Jinan, China

- HS Code:8438800000

- Production Capacity:5000 Sets,Year

=== Description ===

Basic Info.

Customized Customized Material Stainless Steel/Carbon Steel Main Machine Twin Screw Extruder Function Fully Automatic Capacity 100-150g/H 200-250kg/H 300-500kg/H 300-500kg/H 800 Installation Engineer Guide Transport Package Film&Wooden Box Packing Specification 2.5*1.2*1.5m Trademark Donghe Origin Jinan, China HS Code 8438800000 Production Capacity 5000 Sets/YearProduct Description

Product Introduction of Nutrition Cereal Bar Processing LineAs a professional nutrition cereal bar making machine manufacturer, our nutrition bar production line design good manufacturing process. Nutrition bar production line can take oats, rice, black rice, sugar, nuts, corn, barley , wheat, dry fruit, raspberry, blueberry, passionflower and others as raw materials to make the peanut bar for sales. It is popular in the market because of delicious taste, crisp texture, rich nutrition and convenient portability. It has also become the main meal replacement food for fitness people.

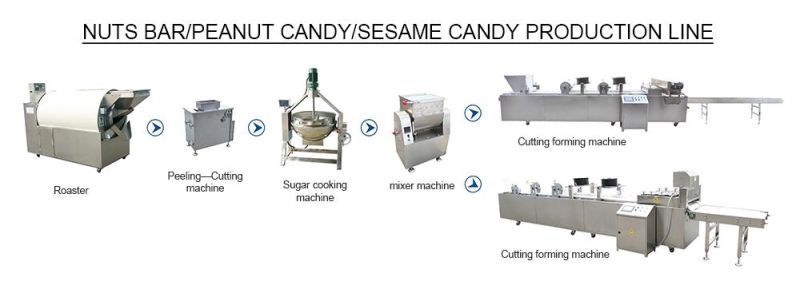

The automatic nutrition cereal bar production line is mainly used for the forming the snack foods such as snack bar, peanut candy, nut candy, granola bar etc. As a professional peanut bar manufacturing equipment supplier, our protein bar manufacturing process machine can make puffing cereal, nuts, dry fruit as raw material, to make cereal bar, granola bar, peanut candy bar, puffed rice bar for sale.

Working Principle of Nutrition Cereal Bar Processing Line

Working Principle of Nutrition Cereal Bar Processing Line

We can provide the full set configuration for our customer, from material mixing to finished packing bag, our granola bar packaging machine can connect with the granola bar machine ,then the finished bar can be delivery directly to packing machine for pack.

Sample Image of Nutrition Cereal Bar

Nutrition bars are a nutritionally balanced product that is easy to consume on a daily basis and generally has a lower calorie content than a regular diet. Nutrition bars can be used as snacks and refreshments, and again as a way to provide more and more complete nutrition and energy for breastfeeding mothers.

Nutrition bars are a nutritionally balanced product that is easy to consume on a daily basis and generally has a lower calorie content than a regular diet. Nutrition bars can be used as snacks and refreshments, and again as a way to provide more and more complete nutrition and energy for breastfeeding mothers.Nutrition bars foods that provide extra energy are particularly attractive to consumers. The success of nutrition and energy bars is also due to their convenience and portability, which makes it easy for consumers to refuel in their lifestyles and is therefore highly respected by all.

Machine Parameters of Nutrition Cereal Bar Processing Line

| Machine Name | Capacity | Dimension |

| 1.Grain puffing machine | 100kg/h | 1320*970*960mm |

| 2.Sugar Cooker | 100L | 1320*970*960mm |

| 200L | 1550*1200*1100mm | |

| 3.Mixing Machine | 3-8kg/time | 800*1400*820mm |

| 12-20kg/time | 800*1650*1600mm | |

| 4.Cereal bar cutting machine /cereal bar press machine | 150-200kg/h | 1880*1110*1160mm |

| 5.Cereal bar packaging machine | 30-200pcs /minute | 3200*600*1000mm |

The production line can be adjusted to meet the production needs of different product specifications. It has frequency conversion speed control, automatic cutting and packing, time saving, labour saving, economic and convenient.

The production line can be adjusted to meet the production needs of different product specifications. It has frequency conversion speed control, automatic cutting and packing, time saving, labour saving, economic and convenient.Service Team

We have a professional after-sales service team, including 10 professional engineers with at least 6 years' experience. They can handle technical advice on manufacturing processes, maintenance, fault diagnosis and troubleshooting.

Services

1. Free pre-sales, in-sales and after-sales advisory services, as well as 24-hour online services

2. Free project planning and design services.

3. Free commissioning of the equipment until everything is in order

4. Free management of the long distance transport of the equipment

5. Free training of equipment maintenance and operation personnel.

6. Free provision of new production technology and recipes.

7. Provide 1 year complete warranty and lifetime maintenance service

Company Profile

The company has taken the lead in passing the ISO9000 quality system certification and the products have passed the CE certification.

Our company has strong technical force, experienced in product manufacturing, and a group of professional R&D personnel, and is a technical and industrial manufacturer integrating design, production and sales. Our company has won the trust and praise of domestic and foreign customers with our high dedication, advanced design concept, reliable product quality and perfect after-sales service system. The company will provide new and old customers with more practical and intelligent products with "professional design attitude and elaborate manufacturing concept".

Thank you for your trust and support!

Shipping Pictures:

Customer Visits

Customer Visits

If you would like to come and visit our factory, you are more than welcome to do so!

Company Honours:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23