High Speed Metal Sheet Fiber Laser Cutting Machine 1530

Taizhou Huangyan Lipeng Machinery Mould Factory / 2022-06-23

- After-sales Service:Free Parts

- Warranty:2 Years

- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Advertising Industry

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

=== Base Info ===

- Model NO.:LF1530

- Structure Type:Gantry Type

- Laser Classification:Solid Laser

- Laser Technology:Laser Vapor Cutting

- Laser Source:Ipg

- Transport Package:Wooden Boxes

- Specification:working size: 1300*2500mm

- Trademark:Lansen

- Origin:China

- HS Code:8456110090

- Production Capacity:300sets,Month

=== Description ===

Basic Info.

Model NO. LF1530 Structure Type Gantry Type Laser Classification Solid Laser Laser Technology Laser Vapor Cutting Laser Source Ipg Transport Package Wooden Boxes Specification working size: 1300*2500mm Trademark Lansen Origin China HS Code 8456110090 Production Capacity 300sets/MonthProduct Description

High Speed Metal Sheet Fiber Laser Cutting Machine 1530LF1530 precision fiber laser cutting machine using imported Japan AC servo drive motor drive system, the machine kinematics grinding stage screw drive, linear guide rail to ensure high-speed equipment, high-precision, high reliability.

Widely used in glasses, electronics, appliances and other precision machinery, hardware, microelectronics industry.

Metal Laser Cutting Machine Features:

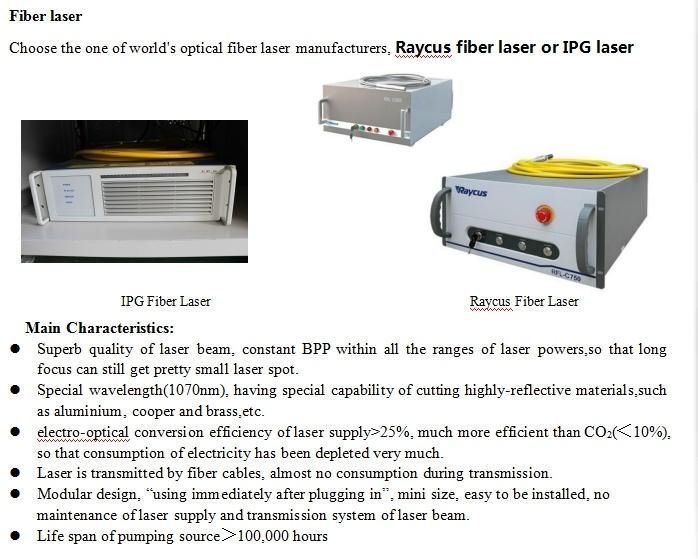

1. It adopts advanced branded optical fiber laser core technology,good optical mode,stable performance.

2. High efficiency of photoelectric conversion,twice of domestic laser source.

3. Low heat of laser source,only needing 5P water cooling machine,saving electricity.

4. The gantry flying light path design,light operation,saving about 40% electricity than competitors.

5. Achieve a perfect cutting effect by only blowing compressed air during processing,which can largely reduce costs of auxiliary

gas such as Oxygen.Nitrogen about thousand dollars,

6. Equipped with centralized lubrication system to make the machine run more stable.

7. Axial positioning accuracy of workbench: ≤±0.03mm/m

8. Repetitive positioning accuracy of workbench: ≤±0.03mm/m

Model | LP-M1530F |

Work size | 1500*3000mm |

Laser type | Fiber laser |

Laser working medium | Fiber |

Laser wavelength | 1070 nm |

Rated output power | 1000W/1500W |

Beam quality | <0.373mrad |

Table axial positioning accuracy | ≤±0.02mm/m |

Repeat positioning accuracy table | ≤±0.02mm/m |

Cutting speed | ≤20m/min |

XYZ Driving mode | Imported servo motor |

Transmission mode | Ballscrew |

Power Ratings | Three-phase AC 380V 50Hz |

Equipment Weight | 3200Kgs |

Optical parameter | 1000W/1500W |

Operational mode | CW,QCW |

Wavelength of the center radiation | 1070-1080nm |

Standard power output | 500W |

Optical quality | 4mm*mrad |

SPD speed | 5kHz |

Optical fiber diameter | ≥50μm |

Output power stability (long-term) | ±2% |

Power supply | 400-460VAC |

Power consumption (including supporting annex) | 33 |

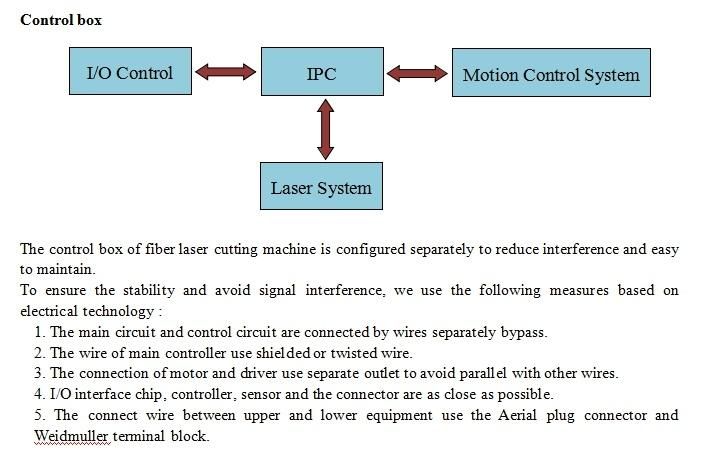

Machine details:

Application:

LF1325 1530 Fiber Laser Cutting machine:

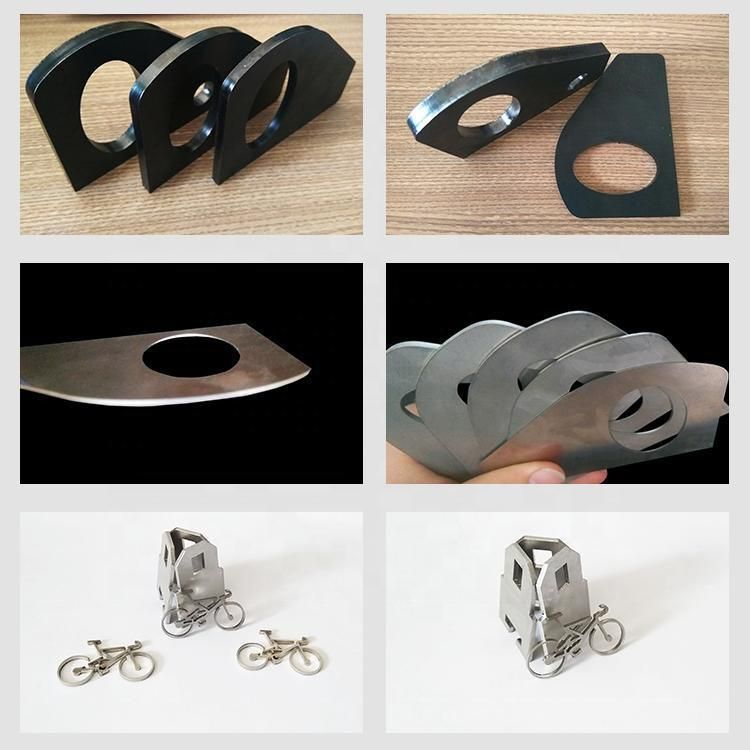

Professional used to cut thin sheet metal, in a variety of high quality 0.5-12 mm carbon steel sheet cutting, also cut stainless steel plate, aluminum alloy plate, galvanized sheet, electrolytic plate, silicon steel, titanium alloy, aluminum zinc plate and other metal materials.

Widely used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, automobile, food machinery, textile machinery, engineering machinery, precision parts, ships, metallurgy equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, and other fields.

Packaging&Shipping:

Trade Terms: EXW, FOB, CNF, CIF, DDU, DDP, etc.

Supply Ability: 100 sets / Month

Port: Qingdao

Payment: T/T (Bank Transfer), western union, moneygram, PAYPAL payments for offline orders.

Packaging Detail: International standard plywood export box

Shipping: BY SEA, BY LAND, BY AIR OR BY EXPRESS

Warranty:1. InstallationAfter the machine reach the buyer's site,the engineers from the seller are responsible for machine installation and commissioning by using the special tools under the help of the buyer. And then start training the workers. Tickets, hotel and food charge need to afford by buyers

2. Training

- The common protection knowledge of laser safety

- The basic principle of laser module and the structure of laser cutting machine

- The operation skills of fiber laser cutting machine

- Equipment operation and the application notice

- Skills of equipment daily maintenance,laser module adjustment and spare parts replacement.

- Training time is about 5 to 10 days.

About us:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23