50t/24h Maize Flour Milling Machine for Africa

Nanjing Zhanyi Technology Co., Ltd. / 2022-07-05

- Warranty:1year

- Type:Flour Mill

- Application:Flour, All, Corn,Wheat, Rice,Millet, Sorghum, Buckwheat.Others

- Voltage:380V

- Appearance:Vertical

- Press Materials:Corn

=== Base Info ===

- Model NO.:maize flour milling machine

- Press Series:Fourth

- Condition:New

- Customized:Customized

- Capacity:According to Customers′ Need

- Place of Origin:Henan, China (Mainland)

- Machine Test:Supported

- Transport Package:Seaworthy Wood Case

- Specification:CE, SGS, CCC, ISO

- Trademark:LY

- Origin:Jiaozuo of Henan Province

- HS Code:8437800000

- Production Capacity:200 Sets Per Month

=== Description ===

Basic Info.

Model NO. maize flour milling machine Press Series Fourth Condition New Customized Customized Capacity According to Customers′ Need Place of Origin Henan, China (Mainland) Machine Test Supported Transport Package Seaworthy Wood Case Specification CE, SGS, CCC, ISO Trademark LY Origin Jiaozuo of Henan Province HS Code 8437800000 Production Capacity 200 Sets Per MonthProduct Description

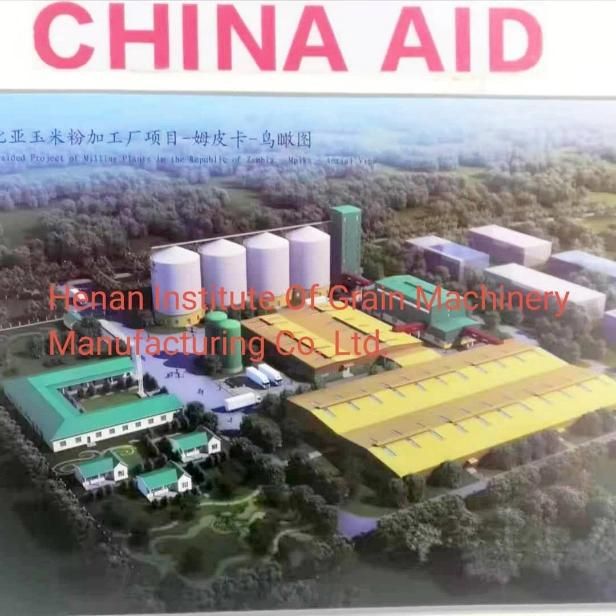

50t/24h Maize Flour Milling Machine for AfricaBrief introduction of corn/maize flour milling machine

Adopting the dry process technique, FTA complete set maize milling machine can produce low fat corn grits, corm meal, corn flour with different at the same time. The whole line consisits of corn seeds cleaning, peeling, degerming, crushing, gentle milling, sifting and flour bagging.

Advantages of corn/maize flour milling machine:

1. Turnkey project 10T-500T/D complete maize flour milling machinery.

2. Advanced technology support and customized design.

3. Thorough crafts and rational allocation.

4. Dust-free design and low power consumption.

5. Perfect after-sales service.

6. One year guarantee.

Using dry peeling and degerming technology, it can produce different sizes of corn grits and flour at the same time. Corn grits size can be customized as per customers' need in order to meet various of needs such as brewery, snack food, glucose, sugarhouse. Thanks for the dry peeling and degerming technology, husks and germs collected at the end don't need to be dried before used for animal feed.

Features of the corn milling line: Simple to operate, easy to maintain, and better than just about anything else at what it does.

Working process of corn milling line:

Cleaning and stone removing - peeling - polishing and degerming - milling - sifting - milling

Final products parameter of the corn milling machine

1. Sand content: <0.02%

2. Metal content: <0.003g/kg

3. Water content: 13.5-14.5%

4. Color and smell: Regular

| Final products | Output rate | Fat content | Size |

| Corn grits | 45-55% | <0.8% | Mesh 8-40 |

| Corn flour | 20-30% | <1.5% | Mesh 50-80 |

| Animal feed | 25% | High | Normal |

| Model | Capacity (per 24hs) | Total power(kw) | Working space(m) | Power consumption |

| FTA-150 | 150 tons | 365 | 27*7*8 | 50kwh/t |

| FTA-100 | 100 tons | 285 | 27*7*8 | 50kwh/t |

| FTA-50 | 50 tons | 128 | 13*5*6 | 50kwh/t |

| FTA-30 | 30 tons | 105 | 10*5*5.5 | 55kwh/t |

Machine relative index of maize flour mill

A. Technical index:

1. Product type: Corn grits, corn flour, corn bran;

2. Power consumption: 60kwh/ corn ton;

3. Product yield: Cron grits: About 45-55%,

Corn flour: About20-30%;

Corn bran: 25% or so;

Corn grits and corn flour total yield: 75-80%

B. Product quality index:

1. Corn flour thickness: 40-120 mesh ( thickness can be adjusted);

2. Sand content: Not more than 0.002g/kg;

3. Magnetic metal content: Not more than 0.003g/kg;

4. Water: Preservable: 13.5-14.5%;

5. Color and odour: Pink. Odour: Taste normal;

6. Fat content: 0.5-1%

C. Equipment total power: 105kw

D. Equipment land occupation: (length*width*height): According to Corn/Maize Capacity

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23