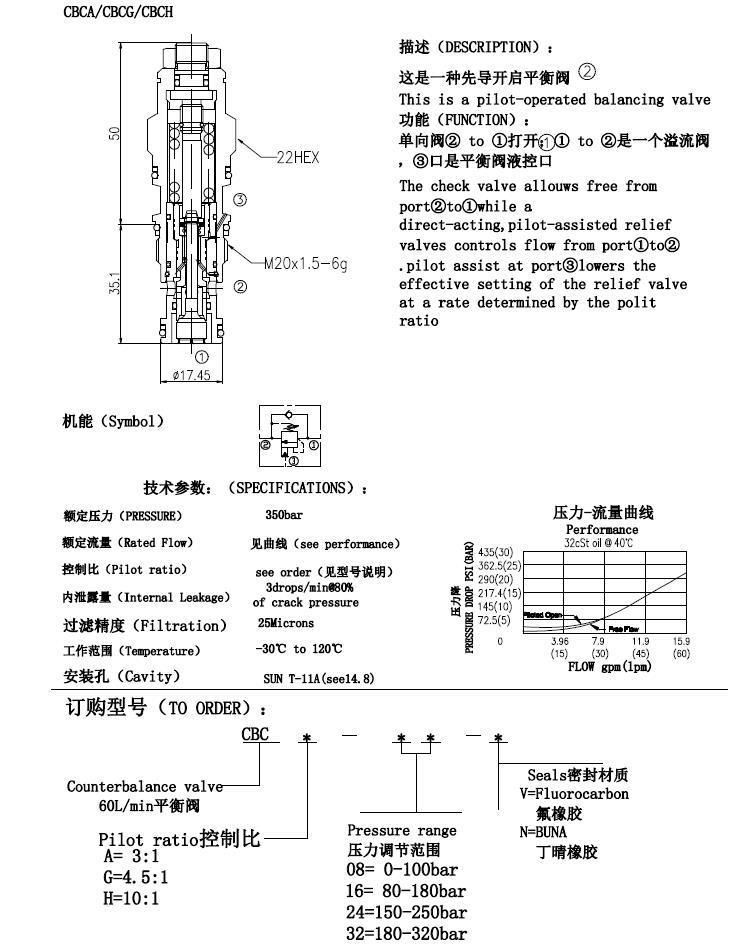

60L CBCH 10:1 pilot ratio, standard capacity counterbalance valve

Suzhou Best Link New Material Co., Ltd. / 2022-06-27

- Function:Balance

- Installation:Threaded Cartridge

- Drive:Hydraulic

- Type:Pilot-Operated Type

- Pressure:350bar

- Flow:60L,min

=== Base Info ===

- Model NO.:CBCH

- Cavity:T-11A

- Pilot Ratio:10:1

- Factory Pressure Settings Established at:2 in3;,min

- Maximum Valve Leakage at Reseat:5 drops,min

- Adjustment - No. of CCW Turns from Min.:3.75

- Fluid:Mineral Oil or Phospate Ester

- Temperature Rang:-30-120 Celsius Degree

- Protection to DIN:IP65

- Certificate:ISO9001

- Transportation:Ocean,Land,Air,Express

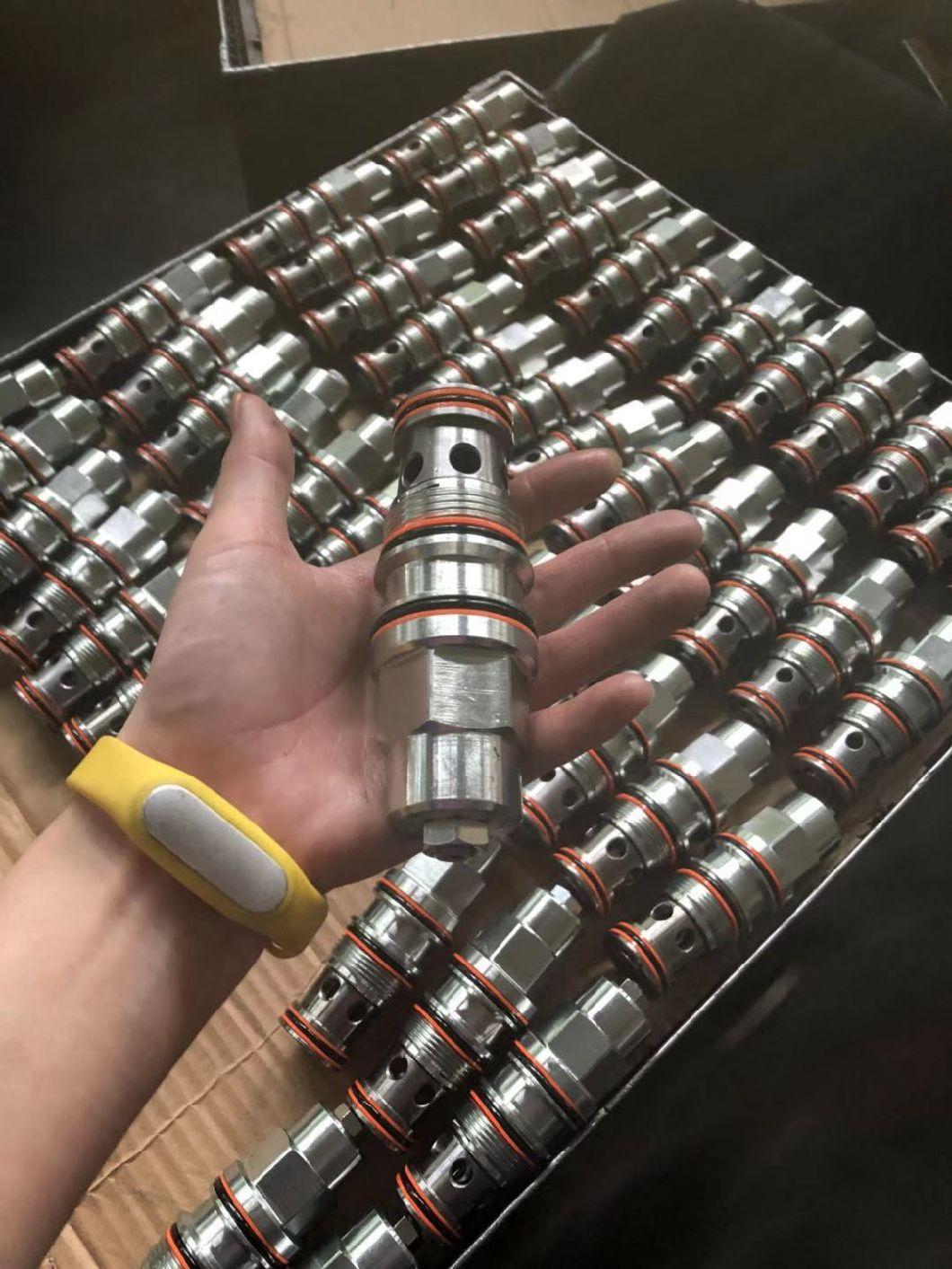

- Transport Package:Cartons and Pallets

- Specification:T-11A

- Trademark:Longli

- Origin:China

- HS Code:8412291000

- Production Capacity:5000PCS,Year

=== Description ===

Basic Info.

Model NO. CBCH Cavity T-11A Pilot Ratio 10:1 Factory Pressure Settings Established at 2 in3;/min Maximum Valve Leakage at Reseat 5 drops/min Adjustment - No. of CCW Turns from Min. 3.75 Fluid Mineral Oil or Phospate Ester Temperature Rang -30-120 Celsius Degree Protection to DIN IP65 Certificate ISO9001 Transportation Ocean,Land,Air,Express Transport Package Cartons and Pallets Specification T-11A Trademark Longli Origin China HS Code 8412291000 Production Capacity 5000PCS/YearProduct Description

DESCRIPTION & OPERATION

Counterbalance valves with pilot assist are meant to control an overrunning load. The check valve allows free flow from the directional valve (port 2) to the load (port 1) while a direct-acting, pilot-assisted relief valve controls flow from port 1 to port 2. Pilot assist at port 3 lowers the effective setting of the relief valve at a rate determined by the pilot ratio.

Other names for this valve include motion control valve and over-center valve.

FEATURES:

- Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

- Turn adjustment clockwise to decrease setting and release load.

- Full clockwise setting is less than 200 psi (14 bar).

- Backpressure at port 2 adds to the effective relief setting at a ratio of 1 plus the pilot ratio times the backpressure.

- Reseat exceeds 85% of set pressure when the valve is standard set. Settings lower than the standard set pressure may result in lower reseat percentages.

- Sun counterbalance cartridges can be installed directly into a cavity machined in an actuator housing for added protection and improved stiffness in the circuit.

- Two check valve cracking pressures are available. Use the 25 psi (1,7 bar) check unless actuator cavitation is a concern.

- This valve does not have positive seals on the pilot section and will pass between 2 and 20 in³/min./1000 psi (0,03 and 0,3 L/min./70 bar) between port 2 and port 3, depending on load pressure. This is a consideration in master-slave circuits and in the leak testing of valve-cylinder assemblies.

- All 3-port counterbalance, load control, and pilot-to-open check cartridges are physically interchangeable (i.e. same flow path, same cavity for a given frame size).

- Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage the seals.

- Corrosion resistant cartridge valves are intended for use in corrosive environments and are identified by the model code suffix /AP for external stainless steel components, or /LH for external zinc-nickel plated components. See the CONFIGURATION section for all options. For further details, please see the Materials of Construction page located under TECH RESOURCES.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

| Cavity | T-11A |

| Series | 2 |

| Capacity | 60L |

| Pilot Ratio | 10:1 |

| Maximum Recommended Load Pressure at Maximum Setting | 280bar |

| Maximum Setting | 350bar |

| Factory Pressure Settings Established at | 2 in³/min. |

| Maximum Valve Leakage at Reseat | 5 drops/min. |

| Adjustment - No. of CCW Turns from Min. to Max. Setting | 3.75 |

| Operating Characteristic | Standard |

| Reseat | >85% of setting |

| Model Weight | 0.16kg |

Why Choose Us

1. With 30 years experience of hydraulic components in china.

2. Best manufacturing machinery, quality level, best price, best service.

3. We have very good and comprehensive after-sales service.

4. We have no MOQ for clients and tailor0made to clients request for our huge inventory.

Our Service

Pre-sale service: we provide presales in our first cooperation make clear your situation and give you some advice.

In-sale Service: We will track the production progress and quality, check the exact model and quantity one by one before delivering.

After-sale Service: We will provide a one year free warranty and lifetime maintenance. We will change all questions in 7*24hours if you buy from us.

Packing

Eternal Brand, Neutral or Customer's requires label.

Neutral carton or same as the Customer's requires, export standard carton.

All cartons should be packed into the pallets more carefully.

All of the productions are inspected carefully one by one by QC before delivery.

Payment term:

T/T 50% as deposit in advance, the balance should be paid before delivery.100% L/C is acceptable. Western Union and PayPal is acceptable.

Transportation: By sea; By air; By truck; By express (DHL,TNT,UPS,FEDEX)

Trading term: FOB,CFR,CIF

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23