PVC Plastic Pipe Extrusion Line Mixier Cutter Line

Hengshui Xinliyuan Technology Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description === Twin Screw Extruder

Twin Screw Extruder

1.Siemens PLC

2.Quality Screw and Barrel

3 Air Cooled Ceramic Heater

4 High Quality Gearbox and Distribution Box

5 Better Cooling of Gearbox

6 Advanced Vacuum System

7 Easy Cable Connection

Both conical twin screw extruder and parallel twin screw extruder can be applied to produce PVC pipe. With latest technology, to

lower power and ensure capacity. According to different formula, we provide different screw design to ensure good plasticizing

effect and high capacity.

Cooling Tank

Cooling Tank

1 Pipe Clamping Device

2 Water Tank Filter

3 Quality Spray Nozzle

4 Pipe Support Adjusting Device

5 Pipe Support Device

Cooling tank is used to cool pipe further.

Haul off unit

1 Pipe Clamping Device

2 Water Tank Filter

3 Quality Spray Nozzle

4 Pipe Support Adjusting Device

5 Pipe Support Device

Haul off unit provides sufficient traction force to pull pipe stably. According to different pipe sizes and thickness, our company

will customize traction speed, number of claws, effective traction length. To ensure match pipe extrusion speed and forming speed,

also avoid deformation of pipe during traction.

Cutter

Cutter

1 Aluminum Clamping Device

2 Advanced Hydraulic System

3 Dust Collection System

Cutter controlled by Siemens PLC with chamfering function, working together with haul off unit to have precise cutting. Customer

can set the length of pipe they want to cut.

Stacker

1 Pipe surface protection

2 Central Height Adjustment

To support and unload pipes. Length of stacker can be customized.

Coiler

Coiler

Use for servo motor

To coil pipe into roller, easy for storage and transportation. Usually used for pipe below size 110mm. Have single station and

double station for choice.

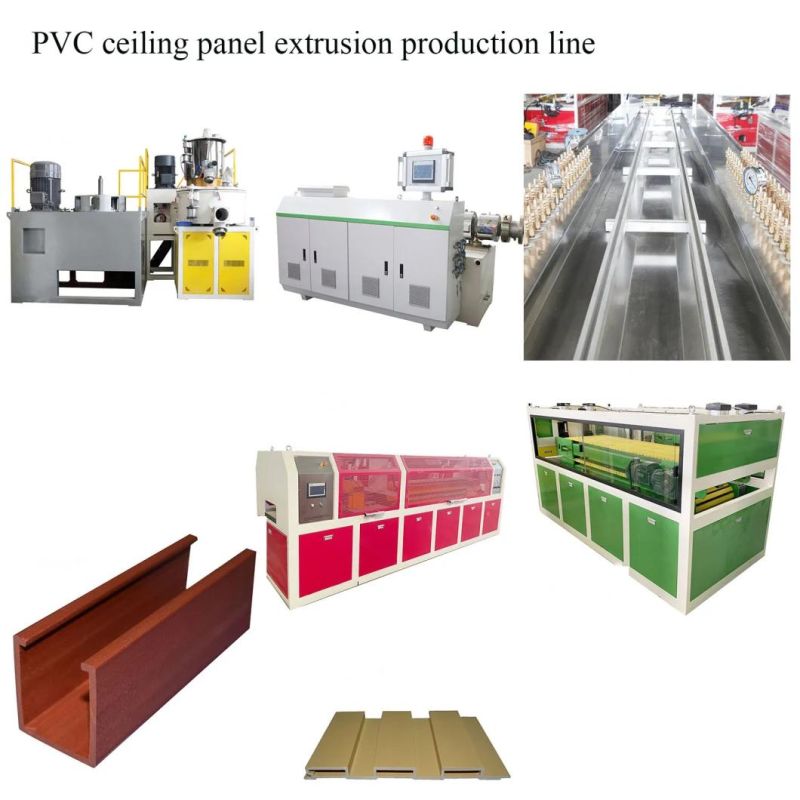

PVC ceiling panel sheet extrusion production line.

PVC ceiling panel sheet extrusion production line.New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23