Starch Mould Jelly Candy Production Line

Hubei Hawking Packaging Material Co., Ltd. / 2022-07-05

- Certification:CE

- Power Source:Electric

- Process:Producing

- Automatic Grade:Automatic

- Application:Candy

- Customized:Customized

=== Base Info ===

- Model NO.:DR-SM8000

- Machinery:Jelly Candy Production Line

- Transport Package:Pallet

- Specification:CE

- Trademark:D&R

- Origin:China

- HS Code:8438200000

- Production Capacity:500-1000kgs,Hour

=== Description ===

Basic Info.

Model NO. DR-SM8000 Machinery Jelly Candy Production Line Transport Package Pallet Specification CE Trademark D&R Origin China HS Code 8438200000 Production Capacity 500-1000kgs/HourProduct Description

STARCH MOGUL LINEDESCRIPTION

D&R mogul plant especially producing gummy candies. With high quality, easy operation, working reliable, with high output. The whole plant including kitchen system, mogul plant, starch conditioning system, starch collecting and recycling system, product finishing and ancillary machinery.The plant suit for producing gelatin

base candies, foamed candies and so on. Whatever your production requirements, D&R

Has the right solution. We offer different types of depositors to cater to your needs for flexibility and speed. We offering the depositing type with SWING, ONE SHOT, SERVO DRIVEN FOR CENTRE FILLED GUMMIES AND STRIPER GUMMIES.

SPECIFICATION

Production capacity 6000kg/8h(Depends on the shape of candy)

Power 95KW(Depends on the machine type)

Steam 7-8 bar 850kg/h

Constringent air 0.6mpa 400m3h

4 Degree cooing flux 315kg/min(no this item if cooling by air or water)

Purpose And Characteristic:

D&R mogul plant especially producing gummy candies. With high quality, easy operation, working reliable, with high output. The whole plant including kitchen system, mogul plant, starch conditioning system, starch collecting and recycling system, product finishing and ancillary machinery. The plant suit for producing gelatin base candies, pectin base candies, modified starch base candies, carrageenan base candies, foamed candies and so on. Whatever your production requirements, D&R has the right solution. We offer different types of depositors to cater to your needs for flexibility and speed. We offering the depositing type with SWING, ONE SHOT, SERVO DRIVEN FOR CENTRE FILLED GUMMIES AND STRIPE GUMMIES.

Our Advandages:

1.D&R Industries With Many Years Experience

2.High Technology team

3.Giving The Whole Project Solution

4.Consulting For Candies, Gummy, Chocolate And Its Packing

5. Always Giving The Economic Machine

6.Better Quality, Better Service After Sales For All Of The Customer

Company Introduction:

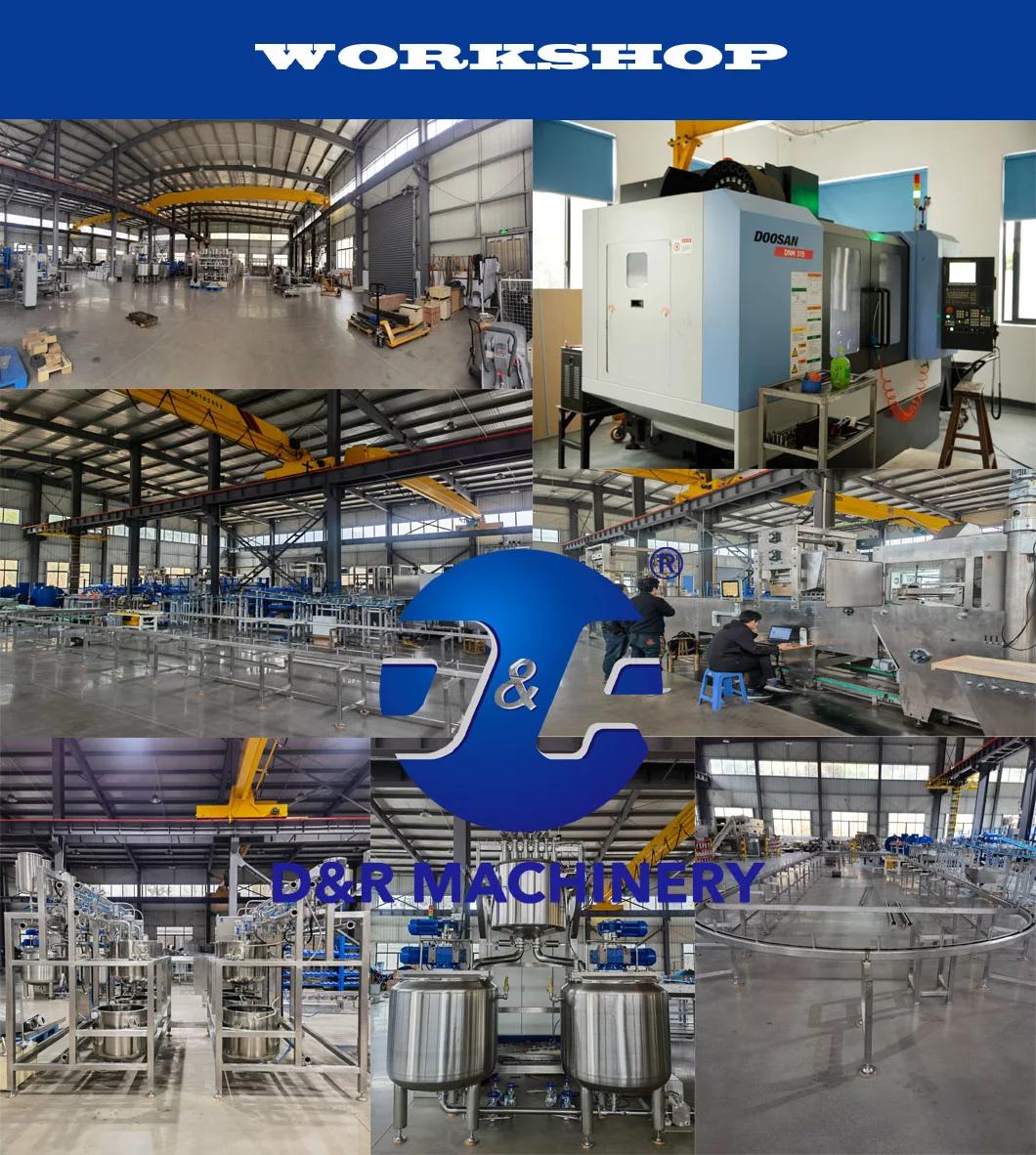

TOTAL SOLUTION ,TOTAL CARE

D&R Machinery are professional confectionery machine manufacturers with over 10 years in the business operating at the highest industry standards.

We've built a reputation on engineering, designing and delivering high performance total-solution confectionery machinery to clients with absolute precision around the world.

The confectionery machinery industry is a small world, and we've slowly become leaders in innovation and creative solutions for clients from all walks of the industry. D&R Machinery has become synonymous with one word and one world only in the confectionery machinery world and that is 'total-solution', that is end to to end turn key production of the highest quality confectionery machinery in the world.

Becoming the D&R Machinery you see today starts and ends with the word 'care'. You don't become the best without a plan that ensures our clients achieve the success they desire, and at D&R Machinery it starts with care and ends with trust, reliability and innovation.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23