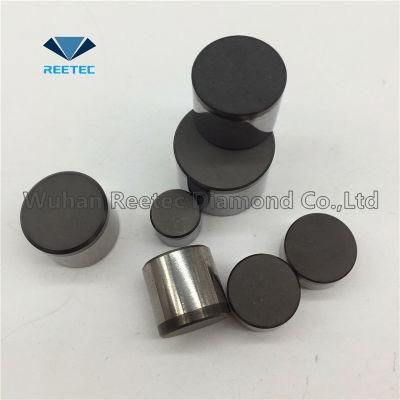

High Wear Resistance PDC Cutters for Reamer Bits

Laizhou Dechen Machinery Co., Ltd. / 2022-06-27

- Type:Polycrystalline Diamond Compact

- Surface Finishing:Fine Wear

- Blade Material:Diamond

- Tip Material:Diamond Button

- PDC Button Shape:Spherical,Ballistic,Parabolic,Flat

- Body Material:Tunsgten Carbide

=== Base Info ===

- Model NO.:1008,1308,1313,1613,1616,1916,1919

- Characters:Wear Resistance

- Transport Package:Plastic Box

- Specification:1308, 1313, 1613, 1616, 1913, 1916

- Trademark:Reetec

- Origin:Wuhan

- HS Code:82071910

- Production Capacity:400000PCS,Year

=== Description ===

TRA / Soft condition/Gage PDC

4. Company Introduction

Wuhan Reetec Diamond Co., Ltd. (Wuhan Reetec for short) is a specialized company engaged in diamond composite materials research and development, design and manufacture, the main products PDC cutters and top dome PDC inserts are widely used in petroleum geological drilling and exploration, coal mining, road and bridge engineering excavation, as well as other areas of abrasion resistant tools.

With strong supports from the R&D system of Kingdream Public Limited Company(Kin gdream for short), Wuhan Reetec Diamond Co., Ltd was established and registered in Wuhan East Lake New Tech Development Zone on December 28, 2002. In 2006, Reetec passed ISO9001-2000 QMS Certification. In 2008, The Company was recognized as a National Hi-Tech. Enterprise, and passed ISO 9001-2008 QMS Renewal Certification in 2010.

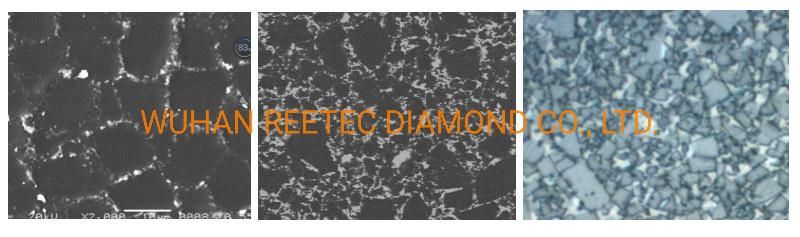

5. R & D Capability

Wuhan Reetec and Kingream had established a lab to improve the performance of PDC materials.

Testing of basic characteristics

Density of PCD

Surface resistance of PCD

Magnetic property of PCD

Content of Co/tungsten/carbide and other elements

SEM analysis of PCD layer and substrate

Bending strength test of PCD

Residual stress of PCD surface

Material property of carbide substrate

Testing of macro performances

VTL test

Abrasive test

Impact test

Thermal stability test

Product Physical and Chemical Analysis

Microstructure:

Thermal Stability Test:

Destructive Impact Test

Patents and Certificates of Honor

FAQ

| Type of Company | Manufacturer |

| Founded in | 2002 |

| Sample Order | Accept |

| OEM | Available |

| Quality Control | Each product will be inspected in strict procedure before delivery |

| After-sales Service | If quality problem, goods can be return or replaceable. |

| Payment Terms | 50% in advance by T/T, delivery against balance |

| Delivery Time | 7-14 days after receipt |

| Packing | Plastic box |

| Factory Location | Wuhan, Hubei Province |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23