Fw-12030c Tube Fibre Laser Cutting Machine with a Maximum Load of 900kg/2000ibs

Foshan Hengyi Plastics Color Printing Factory / 2022-06-23

- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Aerospace Industry, Automotive Industry

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

- Structure Type:Desktop

- Laser Classification:Free Electron Laser

=== Base Info ===

- Model NO.:FW-8020C

- Laser Technology:Laser Vapor Cutting

- Lead Time:15 Days

- Guarantee:24 Months

- After-Sale Service:Field Guidance,Online Instruction Offered

- Laser Head:Raytool

- Laser Source:Ipg,Raycus

- Driving System:Yaskawa,FUJI

- Motor:Yaskawa,FUJI

- Linear Guide:Bosch Rexroth,Hawkking

- Precision Reducer:Shimpo

- Pipe Shape for Cut:Circular,Retangualr,Oval etc

- Cutting Length:Per Request

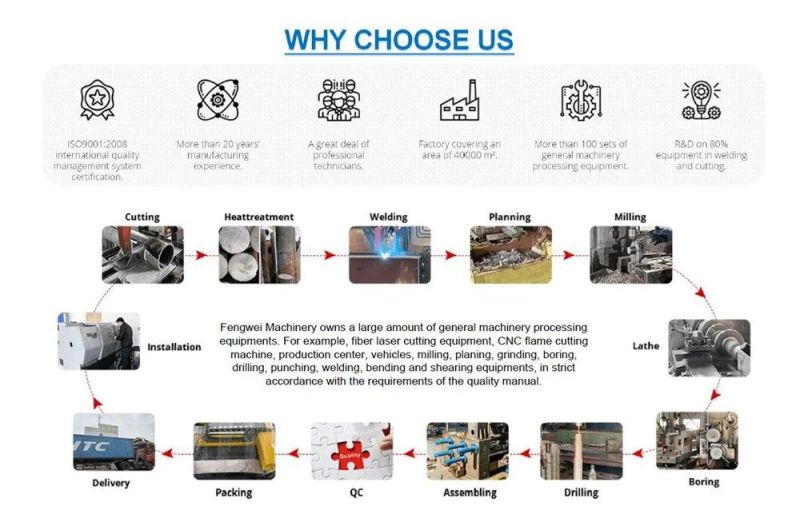

- Manufacturer:Fengwei

- Notes:Please Provide Your Preferred Brand for Precise Qu

- Transport Package:Export Standards

- Trademark:Fengwei

- Origin:Shanghai

- HS Code:8456110090

=== Description ===

Basic Info.

Model NO. FW-8020C Laser Technology Laser Vapor Cutting Lead Time 15 Days Guarantee 24 Months After-Sale Service Field Guidance/Online Instruction Offered Laser Head Raytool Laser Source Ipg/Raycus Driving System Yaskawa/FUJI Motor Yaskawa/FUJI Linear Guide Bosch Rexroth/Hawkking Precision Reducer Shimpo Pipe Shape for Cut Circular/Retangualr/Oval etc Cutting Length Per Request Manufacturer Fengwei Notes Please Provide Your Preferred Brand for Precise Qu Transport Package Export Standards Trademark Fengwei Origin Shanghai HS Code 8456110090Product Description

Product DescriptionAutomatic Laser Tube Cutting Machine brief introduction:

- From small diameter tubes to large tubes for structural applications, there is a Tube Laser Model for every application

- 2D Laser Cutting Solutions: cut off features and joints between tubes in frames and structures.

- 3D Laser Cutting Solutions: tilt cutting or chamfering in thick walled parts for weld prep.

- All-in-house manufacturing provides you quality and assurance.

- Available for site check/live broadcast of cutting

- Automatic Tube Bundle Loading

- Automatic Material Alignment

- Automatic Feeding and Rotation

- Unloading

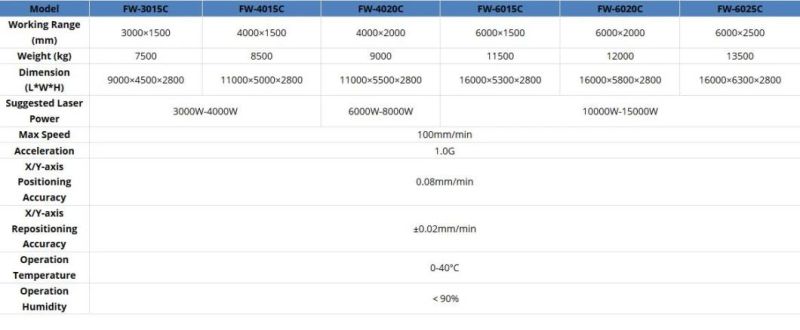

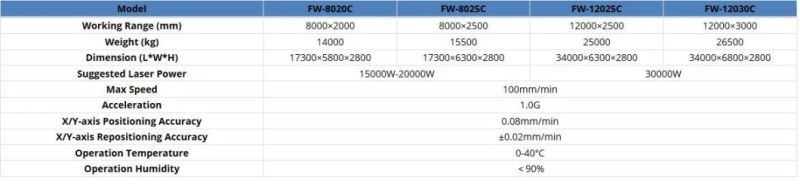

Technical Parameter

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23