GPPS PC PMMA Acrylic Plastic Solid Compact Embossed Sheet Board Machine Extrusion ...

Xinzheng Lifa Abrasives & Abrasives Co. Ltd / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. LSJ-130/38 Computerized Computerized Certification CE, ISO9001:2008 Customized Customized Condition New Sheet Width 1000-2100mm Sheet Thickness 0.8-10mm Sheet Structure Ingle Layer or Co-Extrusion Layers ABA Sheet Applications Interior and Exterior Decoration, LGP Extruder Model Sj-130/38 Single Screw Extruder Max Capacity 600kg/H Die Head Type T-Type, Jc-Times Brand Calibrating Board Three Roller Calendars Guaranteed Time 12 Months Transport Package Wooden Cases With Vacuum Film Specification CE ISO9001-2008, GOST, SGS Trademark Leader Machinery Origin Qingdao of China HS Code 8477209000 Production Capacity 25sets/YearProduct Description

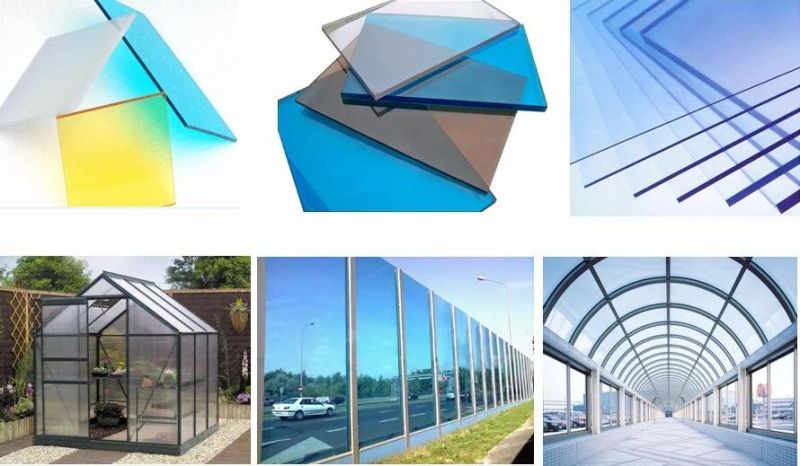

GPPS/PC/PMMA Acrylic Plastic Sheet Board Machine Extrusion Production LineThis extrusion line is specially used to produce the PMMA sheet, which is as clear as glass and has high impact resistance. So it is also called plexi-glass and acrylic sheets. By changing the three rollers calendars, this line can also produce frosted sheets, embossed sheets and other sheets for different applications.

Sheet Specifications:

Thickness: 0.8mm-10mm

Width range: 1000mm-1220mm-1560mm-2100mm

Length: Any dimension.

Color: Clear, blue, green, opal, brown, blue green etc.

Sheet structure: single layer or co-extrusion layers ABA type with UV coating on both sides.

Characteristics and Main Applications:

Characteristics of PMMA sheets:

High transparency, aging resistance, high impact resistance, sound and thermal insulation, UV resistance, heat resistance, fire resistance, light weight, color stability, easy transportation etc.

Main Applications of PMMA sheets:

Interior and exterior decoration(Suspended ceiling, sky light, windows, advertising board, bathroom, kitchen cabinet, aquariums, telephone booth), light box, light guide panel (LGP), advertising lamp, instrument, highway insulation etc.

Machine Specifications and Production Flows:

MD-500 Drying and mixing machine→XAL-3HP Automatic vacuum feeding machine→SJ-130/36 Single screw extruder for PC→Hydraulic screen exchanger for PC→Melting gear pump for PC→SJ-45/30 Single screw co-extruder for UV layer on both sides→Melting gear pump for UV→T-type die head(2300mm width)→Three-roller calendars with 45 degree angle installation →Rollers thermo-controlling machine→Protective film coating unit →Cooling frame & edge cutting device→Haul-off machine with double rollers →Saw cutting machine→Belts conveying table →Sheet stacker

Main Technical Parameters:

| Main extruder Dia. | 120mm | 130mm |

| Main screw L/D ratio | 36:1 | 38:1 |

| Main extruder drive | 185kw | 250kw |

| Co-extruder Dia. | 45mm | 45mm |

| Co-extruder L/D ratio | 30:1 | 30:1 |

| Co-extruder drive | 22kw | 22kw |

| Thickness of sheet | 0.8-8mm | 1.5-10mm |

| Width of sheet | 1000-1560mm | 1220-2100mm |

| Output | ≥420kg/h | ≥600kg/h |

| Power installed | 380kw | 520kw |

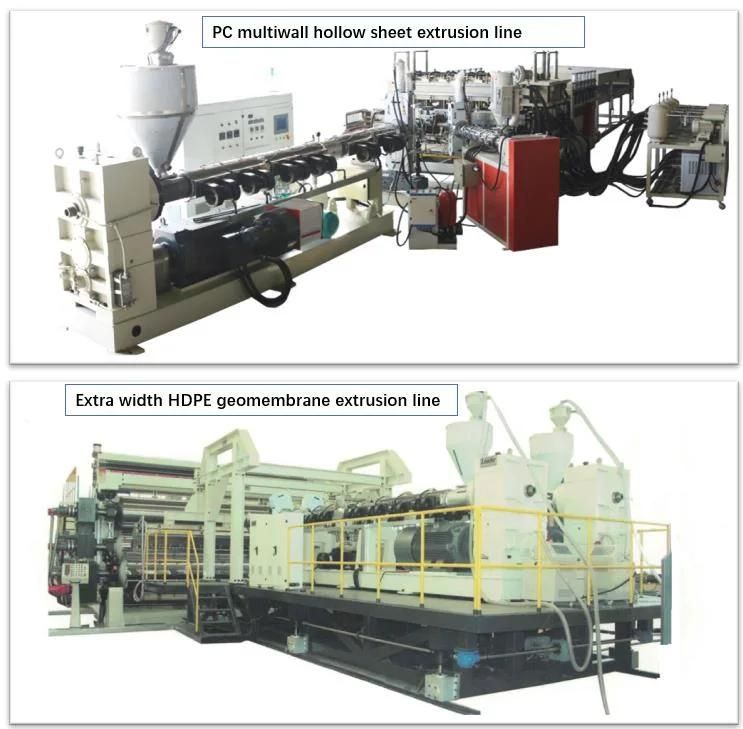

PART 5 SAMPLE PICTURES:

PART 5 COMPANY INFORMATION AND MAIN PRODUCTS:

PART 6 OUR RELIABLE SUPPLIERS:

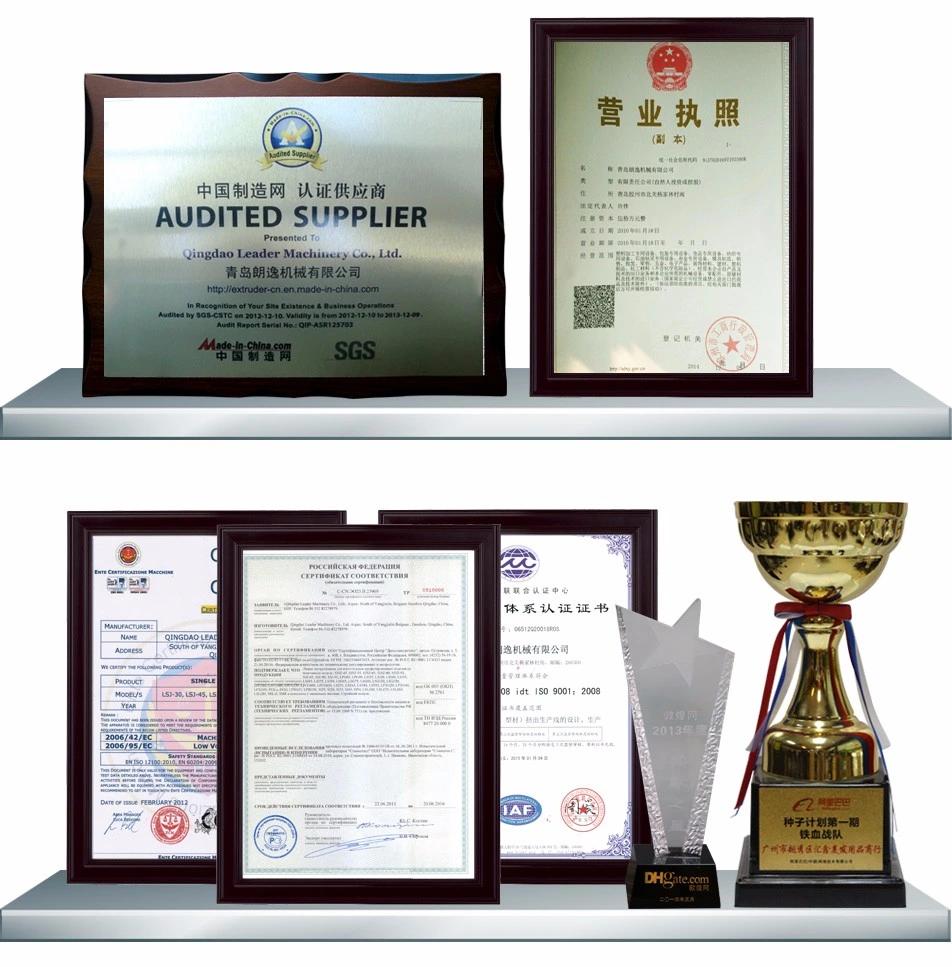

PART 7 COMPANY CERTIFICATIONS:

PART 7 MACHINE PACKING AND DELIVERY

All the machine parts will be packed in wooden cases or pellets with stretching films on machine body.

PART 8 COMPANY OVERSEA SHOWS AND CONTACT DETAILS:

PART 10 OTHER KINDS OF PLASTIC SHEETS/PLATES EXTRUSION LINE RECOMMENDATION :

1. PET sheet extrusion machine:

Processing material: PET virgin pellets(APET or PETG) plus flakes; Or 100% flakes

Thicknes range: 0.2-1.5mm

Net sheet width: 650mm-1500mm(or as per cusotmer's requirement)

Layer structure: Signle layer or multi-layer

Capacity: 150-650kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

2. PP/PS sheet extrusion machine:

Processing material: PP/PS virgin pellets plus recycle material;

Thickness range: 0.15-2mm

Net sheet width: 650mm-720mm-1000mm-1300mm-1500mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1000kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

3. ABS/HIPS sheet extrusion machine:

Processong material: ABS/HIPS virgin pellets plus recycle material

Thickness range: 1-6mm

Net Sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 300-800kg/h

Application: Vacuum forming, thermoforming, refrigerator inner layer, suitcase, etc.

4. ABS/PMMA sheet extrusion machine:

Processing material: ABS/PMMA virgin pellets plus recycle material

Thickness range: 1-8mm

Net sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity:300-800kg/h

Application: Vacuum forming, bathtube, etc.

5. PE sheet extrusion machine:

Processing material: HDPE/LDPE/LLDPE virgin pellets plus recycle material

Thickness range: 1-2.5mm, 3-35mm

Net sheet width: 1200mm-1600mm-1800mm-2500mm-3000mm-40000mm-6000mm-8000mm

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1200kg/h

Application: Packaging, construction, water-proof, water-drainage, Geomembrane film, etc.

6. PC/GPPS/PMMA sheet extrusion machine:

Processing material: PC/GPPS/PMMA virgin pellets plus recycle material

Thickness range: 1-12mm

Net sheet witdh: 600mm-1220mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 200-600kg/h

Application: Ads., decoration, roofing, etc.

7. PC/PP/PE hollow profile sheet/ sunshine roofing panel machine:

Processing material: PC/PP/PE virgin material plus recycle material

Thickness range: 2mm-4mm-6mm-8mm-10mm-12mm

Net sheet width: 1220mm-2100mm

Layer structure: Single layer or multi-layer

Capacity:200-600kg/h

Application: Ads. Decoration, roofing, packaging, printing, etc.

8. PVC sheet/edge banding sheet/marble sheet machine:

Processing material: PVC power plus other additive

Thickness range: 0.15-1mm; 1-3mm; 3-12mm

Net sheet width: 650mm-2000mm-3000mm( or as per customer's requirements)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-500kg/h

Application: Thermoforming, stationery, printing, payment card, SIM card, construction, etc.

9. PVC free foam/celuka foam board extrusion line

board width: 1220mm, thickness: 1-10mm, 3-25mm

board application: decoration board, advertising boards, exhibition boards

extruder model: SJ-80/156 conical twin screw extruder

max capacity: 350kg/h

certifications: CE, ISO9001-2008

10. EVA car interior decoration sheet extrusion line

Processing material: EVA and other additives

Thickness range: 1-8mm

Width range: 1000-1800mm

Layer strcuture: single layer

Capacity: 700-800kg/h

Application: automotive sealing strips, sound insulation cushion, sound absorption sheets,

automobile tail box, fenders, car interior and exterior decoration parts etc.

11. PVC+PMMA Glazed roofing tiles/corrugated sheet extrusion machine

Processing material: PVC, PMMA and other additives

Thickness range: 1-8mm

Width range: 720mm, 880mm, 1040mm

Layer structure: A/B, A/B/A, A/B/C

Capacity: 400kg/h

Application: garden-style factory, tourist scenic spots, pavillions, hotels, family building etc.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23