Factory Price Crusher Knife Automatic Straight Blade Grinding Sharpener Grinder Machine

Guangzhou Ouster Hydraulic Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Blades Grinder

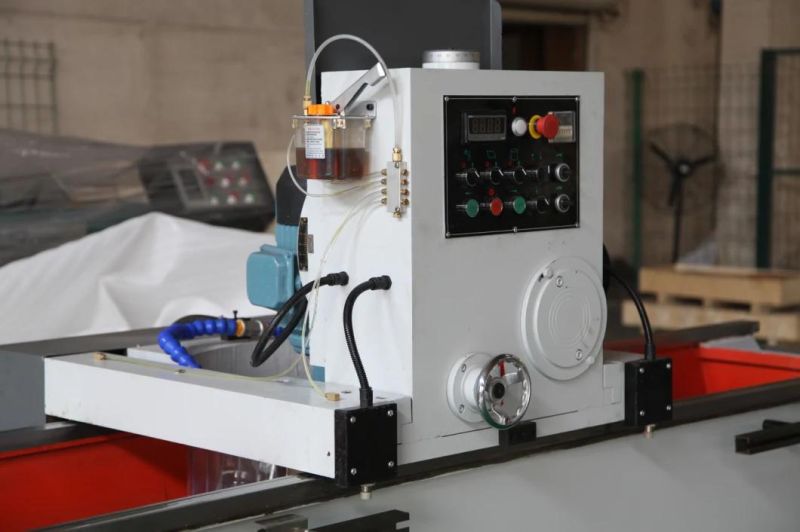

Machine Details Shown >>The operation interface is simple and clear, the knife is automatically dropped, and the feeding frequency can be adjusted;

>>Automatic and manual operation can be freely switched

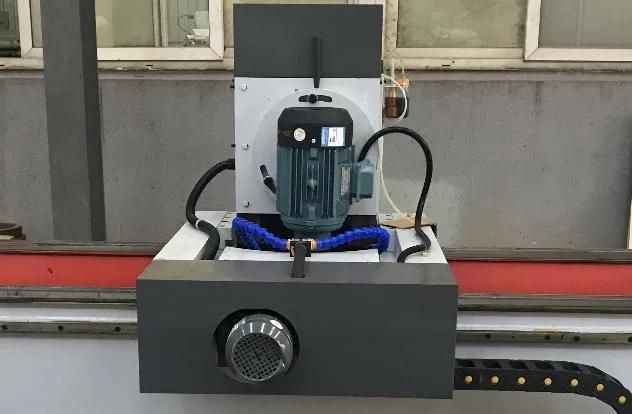

>>Special grinding head motor, good precision, high stability, with fast grinding wheel device, easy loading and unloading

>>Special grinding head motor, good precision, high stability, with fast grinding wheel device, easy loading and unloading>>Strong copper coil electromagnetic chuck, special tool setting device

>>the suction chuck rotates accurately, with automatic locking function, and various types of blade workbenches can be customized.

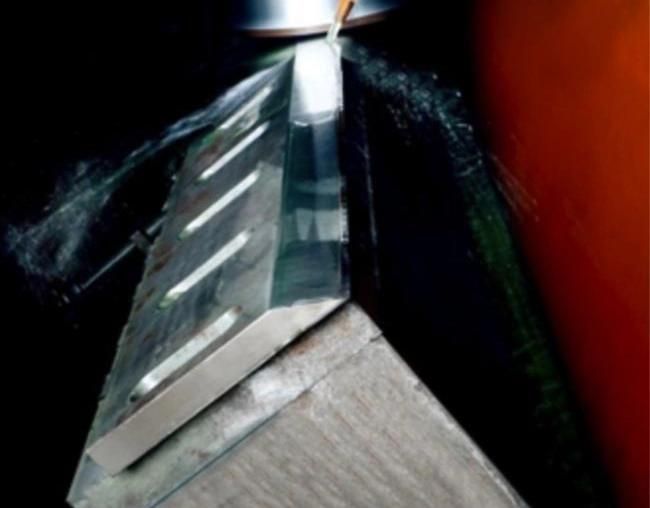

>>the suction chuck rotates accurately, with automatic locking function, and various types of blade workbenches can be customized.>>Blades sample

Complete functions meet various customers' demand

Our Advantage

>> Precision guide rail, the surface is inlaid with high-quality steel belt protection, and the steel belt is easy to replace, the transmission is stable and reliable, and the service life is long.

>> Frequency conversion feed, feed amount and feed frequency are controlled by special frequency conversion; efficient, accurate and convenient.

>> Copper coil powerful electromagnetic suction cup, super suction, stable quality; the suction cup rotates accurately, with automatic locking function, and various types of blade workbenches can be customized.

>> The special grinding head motor can adjust the axial clearance, has high grinding precision, can support large grinding amount, and has a stable service life.

>> The gantry-type bed of the automatic sharpener is welded with high-quality steel plates, and has undergone aging treatment and precision machining, with good precision retention.

>> Centralized refueling device, one-time refueling, saving time and convenience.

Optional parts: polishing side grinding head, fine grinding auxiliary grinding head, secondary edge grinding head.

Machine Photos

How to Ensure the Quality

√ In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

√ Each component before assembly needs strictly control by inspecting personnel.

√ Each assembly is in charged by a master who has working experience for more than 20 years

√ After all the equipment are completed, we will connect all the machines and run the full production line to ensure the stable running

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23