Rice Extruder Machine Artificial Rice Processing Line

ZheJiang Kincess Innovative Materials Co., Ltd. / 2022-07-04

- Processing Material:Wheat Flour,Rice,

- Application:Food

- Customized:Customized

- Certification:CE, SGS

- Power Source:Electric

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:HM65

- Material of Screw:38CrMoAl

- Motor Brand:Siemens

- Inverter Brand:Delta

- Bearings Brand:SKF

- Material of Machine:Stainless Less

- Voltage:220V,380V

- After Sale Service:One Year Free Service

- Warranty:1 Year

- Material of Products:Wheat Flour,Rice etc

- Transport Package:Wooden Package

- Specification:17000*1300*2200mm

- Trademark:Himax

- Origin:Jinan China

- HS Code:8438800000

- Production Capacity:10 PCS, Month

=== Description ===

Basic Info.

Model NO. HM65 Material of Screw 38CrMoAl Motor Brand Siemens Inverter Brand Delta Bearings Brand SKF Material of Machine Stainless Less Voltage 220V/380V After Sale Service One Year Free Service Warranty 1 Year Material of Products Wheat Flour,Rice etc Transport Package Wooden Package Specification 17000*1300*2200mm Trademark Himax Origin Jinan China HS Code 8438800000 Production Capacity 10 PCS/ MonthProduct Description

Rice Extruder Machine Artificial Rice processing lineProduct Description:

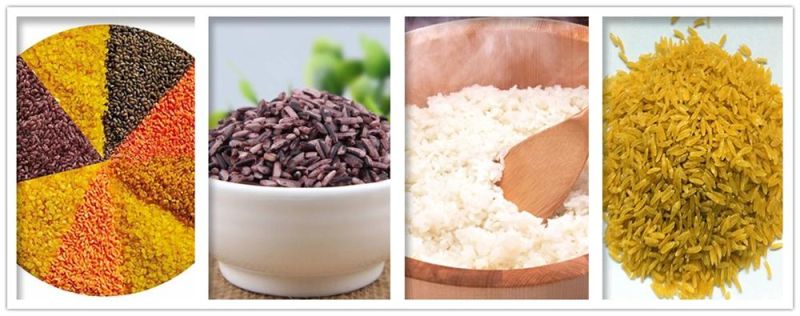

Nutrition Artificial Rice Production Line

Nutrition Artificial Rice Production Line used rice as the main raw material, and some other vitamin and mineral material can be chosen as the products required. The material is extruded into rice shape by the single-screw extruder, dried to required moisture content, and boiled about 5~8min to eat. The extruding technique makes it possible to strengthen the micronutrient in the rice and solidify it.| Model | Power | Output | Size |

| HM-65 | 70KW | 150-180KG/H | 32000*1200*2200mm |

| HM-70 | 90KW | 200-260KG/H | 34000*1500*2200mm |

| HM-85 | 100KW | 300-400KG/H | 36000*1500*3500mm |

Processing Flow Chart

Flour Mixing -- Extruding -- Cooling -- Conveying -- Drying -- Cooling

Equipments List

Mixer-- Screw conveyor-- Extruder--Cooling Conveyor-- Air Conveyor--Dryer -- Cooling Conveyor

Machine details:1. Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

2. Adopting speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process.

3. Gearbox with automatic lubrication function, extending gear life.

4. Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

5. Barrel with watercooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

Samples:

Our Company:

Jinan Himax Machinery Co; Ltd. is a professional supplier of food processing machines. Our company's Motto is: "Technology Makes Easy". We offer to cooperate with our customers for mutual and beneficial development.

We have a group of experienced experts and outstanding engineers who do provide the professional service delivery and installation. Based on the clients specific requirement, we also design and produce the machines to order. We have through the years established good working relationship with some reputable organizations both at home and abroad with outstanding goodwill.

Our main products line include food extrusion machine, soya meal/meat processing machines, industrial micro wave oven, packaging machines, rice cake machine etc... Most importantly, we also provide formulas, technology supports, machine inspection service, etc.

All inquiries are welcome.

Packing and Delivery:

Certificate:

Contact Us:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23