Plastic Blown Film Machine for HDPE LDPE Bags

Nanyang Yukang Photonics Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJ Machine Weight 8T Certification CE, ISO9001:2008 L/D 30:1 Thickness of Film 0.008-0.1mm Max. Extrusion Output 550kg/H Main Motor Power 45kw-55kw Transport Package as Requirement Specification CE. SGS Trademark YunBang Origin China HS Code 8477309000 Production Capacity 20 Sets/MonthProduct Description

plastic blown film machine for hdpe ldpe bags

Characteristic

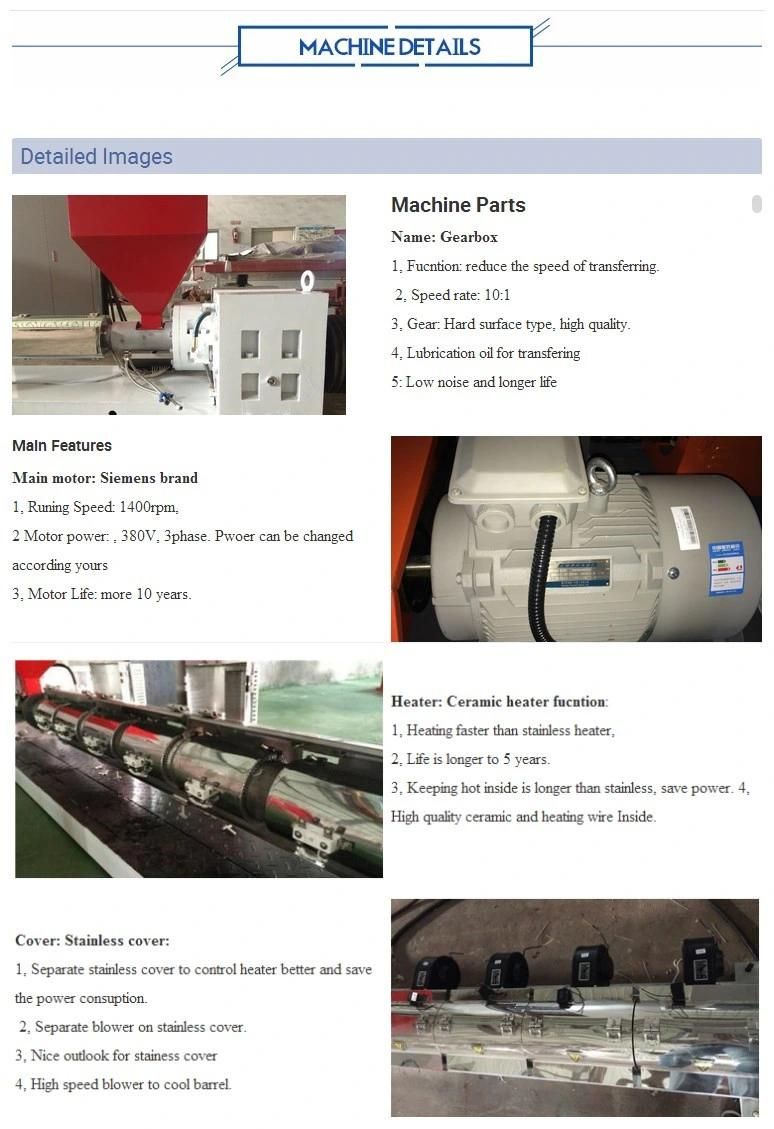

The High speed film blowing machine's extruder, cylinder and screw are made of superior alloy steel that have been nitrified and precision machining. Hence it is sound in hardness, durable in corrosion resistance. The specially-designed screw is sound of quality in plasticizing, which helps increase the production capacity.

Uses

The High speed film blowing machine is applied to blowing the plastic films like low density polygene (LDPE), high density polygene (HDPE) and linear low density polygene (LLDPE). It is widely applied to producing the packing bags for foodstuff, clothing, rubbish bag and vest bags etc.

Performance:

1.Resin: HDPE/LDPE/LLDPE.

2.Designed for T-Shirt bag and flat bag production

Specification:

A.Extruder

1. screw --- SJ-645/superior 38CrMOALA alloy steel nitrified and precision machining.:

Structure: Undulance with mixing head screw (Spraying with alloys)

Normalizing-modulator-remove stress-Nitriding

Nitriding hardness HV890, Nitriding thickness: 0.4-0.7mm

2. barrel---uperior 38CrMOALA/45# inner interval channel, plating hard Cr

with stainless steel heater

3.Gear reducer--- Hard-strength head tooth surface gearbox

4.Drive Motor -----AC motor with inverter

5.Temp control

B. Die

1.Type: Spiral

2. with stainless steel heater

C.Cooling Unit

1.Air blower---With distributor

2.Air ring---Cast Al

D.Take-off Unit

1.Pinch roller----hard-chromium-plated,steel roller and rubber roller

2.Nip pressure system---pneumatic(adjustable)

3.Motor---AC motor with inverter

4.A-form wooden

5.Embossing roller&gusseting unit

6.Bubble cage

E. Winding Unit

1.Type---Surface frication

2.Motor-Torque motor

3.Alarm

F.Control panel

1.Temp controller

2.Mounted meters

A.Input indicating lamp

B.Temp controller

Scale----0°- 399°

Thermocouple

C.Magnetic contactor

D.Ammeter for heater circuit

E.Circuit breaker

F.Speed control meter---for extruder drive&take-off motor

Optional: 1)Auto Loader 2)Embossing Roller 3)Film Surface Treater 4)Die Rotary Device 5)Air Compressor 6)Mechanics Screen Changer.

Model | SJ-50B/FM600 | SJ-55B/FM800 | SJ-60B/FM1000 |

| Screw Diameter | 50mm | 55mm | 60mm |

| Screw Ratio | L/D30:1 | L/D30:1 | L/D30:1 |

| Screw Speed | 10-120r/min | 10-120r/min | 10-120r/min |

| Power of Main Motor | 18.5kw | 22kw | 30kw |

| Max. Extrusion output | 30-60kg/h | 40-80kg/h | 50-100kg/h |

| Max. Folding Width of Film | 600mm | 800mm | 1000mm |

| Single-sided Thickness of Film | 0.008-0.10mm | 0.008-0.10mm | 0.008-0.10mm |

| Sub-master Machine Lift Scope | 800mm | 1000mm | 1200mm |

| Total Power | 28kw | 36kw | 42kw |

| Weight of Machine | 2600kg | 3000kg | 3500kg |

| Overall Dimensions(L×W×H) | 4600×2600×4000mm | 4800×2800×4300mm | 5000×3000×4800mm |

Model | SJ-75B/FM1500 | SJ-90B/FM2000 | SJ-120B/FM2300 |

| screw diameter | 75 | 90 | 120 |

| screw ratio L/D | 28: 1 | 28: 1 | 28: 1 |

| screw speed | 15-100r/min | 15-100r/min | 15-100r/min |

| main motor power | 30-37kw | 37kw-45kw | 45kw-55kw |

| extrusion output(single) | 120kg/h | 145kg/h | 200kg/h |

| range of die | 150, 350 | 500 | 550 |

| single-side thickness of film | 0.01-0.10mm | 0.01-0.10mm | 0.01-0.10mm |

| max. folding width of film | 1500mm | 2000mm | 2300mm |

| electrictotal capacity | 58kw | 80kw | 105kw |

| overall dimension | 5200*3500*6000 | 6800*4000*8500 | 7000*4800*9000 |

| weight of machine | 4.0T | 8.5T | 8.5T |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23