Pear Juice Processing Line /Pear Juice Concentrated Production Line

Nanjing Lipack Import and Export Co., Ltd. / 2022-07-05

- Voltage:up to Customer′s Country Standard

- Type:Processing Line

- Power:up to The Capacity

- Customized:Customized

- After-Sale Service:Engineers Available to Service Machine Overseas

- Final Product Type:Clear Juice, Cloudy Juice, Juice Concentration etc

=== Base Info ===

- Model NO.:JP-APPL-0307

- Capacity:1t-150t,H

- Transport Package:Standard Export Package

- Specification:SUS 304

- Trademark:JP

- Origin:China

- HS Code:8509401000

- Production Capacity:10 Sets

=== Description ===

Basic Info.

Model NO. JP-APPL-0307 Capacity 1t-150t/H Transport Package Standard Export Package Specification SUS 304 Trademark JP Origin China HS Code 8509401000 Production Capacity 10 SetsProduct Description

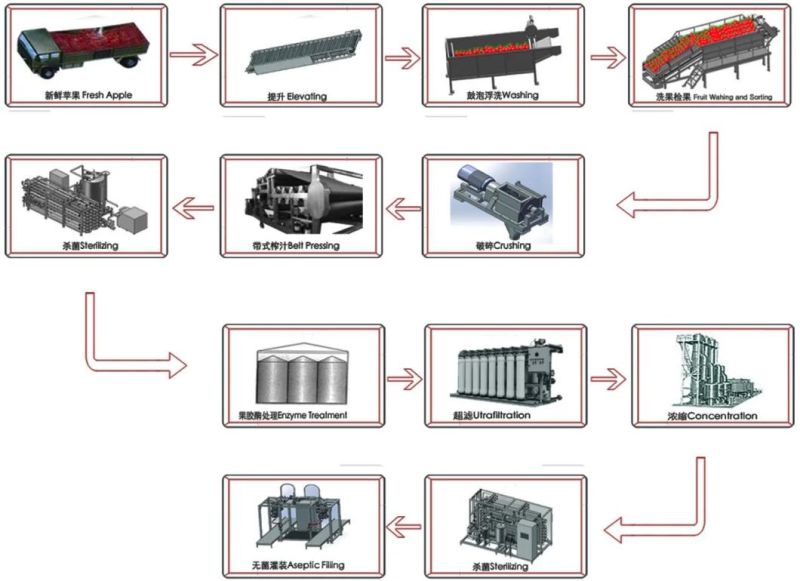

Apple and Pear Juice Processing Line Genreal working process

Description:

This processing line suits for kernel fruits processing ,such as apple, pear and similar fruits, can produce clear juice, turbid juice, concentrated juice and other products.

The production line mainly consist of washing machine, sorting machine, elevators, peeling and crushing machine, belt juicer, enzymatic hydrolysis system, horizontal spiral centrifuge, homogenizer, degasser, sterilizer and filling machine Equipment.Our production line is of advanced design concept and high degree of automation; The main equipment are made by high-quality stainless steel and in full compliance with hygienic requirement of food processing.

We will provide the most thoughtful services for our clients:

1). We make accurate factory layout design according to customer's factory size; if the customer needed, we could make workshop design.2). After receiving firm order and down payment, we start to apply for the Visa to your country immediately; while the machines arrives your factory, our engineers are ready to start for the commissioning service.

3). 1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time.

4). Our engineers have responsibility to teach the workers how to operate, clean, maintain and repair all the machines, until the workers could well operate the processing line.

5). Our engineers can provide basic formula for the production, and help the customer to produce good quality food according customer's detailed formula

6). It normally costs 10-14 days for the commissioning service, and we supply 1 year guarantee from the date of completion of commissioning service.

The process of creating apple/pear juice is energy and capital intensive. So if you are planning to build a plant for apple/pear processing, please feel free to contact us.

Company Overview:

Shanghai JUMP Machinery&Technology Co., Ltd have made brilliant achievements in fruit& vegetable beverage equipment, such as:

1. Juice production line for orange juice, grape juice, jujube juice, coconut drink/coconut milk, pomegranate juice, watermelon juice, cranberry juice, peach juice, cantaloupe juice, papaya juice, sea buckthorn juice, orange juice, strawberry juice, mulberry juice, pineapple juice, kiwi juice, wolf berry juice, mango juice, sea buck thorn juice, exotic fruit juice, carrot juice, corn juice, guava juice, cranberry juice, blueberry juice, RRTJ, loquat juice and other juice drinks dilution filling production line2. Can food production line for canned Peach, canned mushrooms, canned chili sauce, paste, canned arbutus, canned oranges, apples, canned pears, canned pineapple, canned green beans, canned bamboo shoots, canned cucumbers, canned carrots, canned tomato paste, canned cherries, canned cherry

3. Sauce production line for mango sauce, strawberry sauce, cranberry sauce, canned hawthorn sauce etc.

We grasped proficient technology and advanced biological enzyme technology, successfully applied in more than 120 domestic and foreign jam &juice production lines and we has helped client gain excellent products and good economic benefits.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23