Fayon Large Format Thermal Laminating Machine Sign Mounting Table Sign Boards Table Laminator

HENAN YINGKAI TECHNOLOGY DEVELOPMENT CO., LTD. / 2022-06-27

- Type:Laminating Pressing Machine

- Driven Type:Pneumatic

- Power Source:Mechanical

- Application:Machinery&Hardware

- Placing Form:Horizontal

- Computerized:Non-Computerized

=== Base Info ===

- Model NO.:Flatbed lamination

- Usage:Corrugated Paper

- Packaging Material:Plastic

- Highlight:Oversize Lamination

- Structure:Heavy Steel

- Platform Material:Tempered Glass

- Transport Package:Wooden Case

- Specification:L*W*H--3.2*1.6*1.33m

- Trademark:FAYON

- Origin:China

- HS Code:8443911900

- Production Capacity:50sets,Month

=== Description ===

Basic Info.

Model NO. Flatbed lamination Usage Corrugated Paper Packaging Material Plastic Highlight Oversize Lamination Structure Heavy Steel Platform Material Tempered Glass Transport Package Wooden Case Specification L*W*H--3.2*1.6*1.33m Trademark FAYON Origin China HS Code 8443911900 Production Capacity 50sets/MonthProduct Description

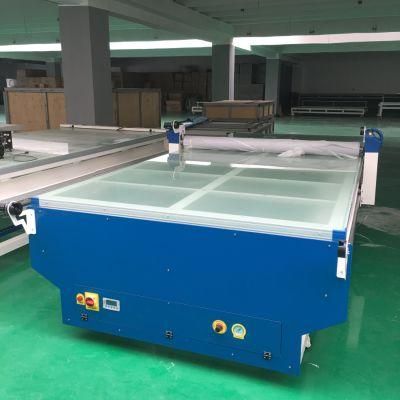

Introduction:FY1530S heavy duty roll prints hot press laminator LED illumination flatbed mounting table

FAYON flatbed workstations is a professional equipment in the printing and post-processing, cater to your varying needs, widely used in the advertising, exhibition organizers, picture production, studio and many other fields, U TRAFAST and EFFICIENT operation on FAYON workstation could save the time-consuming steps in Mounting, Laminating and Masking. Many traditional manual operation are time-costly, complex and technically demanding, but result effect are still uneven. FAYON workstation could finish all the job in a third of time result in a perfect effect!

| Item | Flatbed mounting table |

| Diameter of roller | 130mm |

| Material of rollers | Silicon dioxide,Feature:stability,wear-resisting,anti-aging,moisture proof,Good elasticity,pollution-free |

| Max.effective working size | 1500mm*3000mm(59''x118'') |

| Table glass | 12mm temper glass |

| Illumination | LED tube illumination |

| Guideways | 25mm cylinder guideways,very steady for long time use |

| Machine frame | Steel high temperature weld table,steel strong legs and aluminium profile around the table and gantry |

| Machine paint | Sprayed finished |

| Material roll holder | In front and at behind durable material roll holder and also media roll holder on the gantry |

| Max.filming thickness | 50mm |

| Roller heating: | Internal heating by infrared |

| Temperature range | Adjustable,environmental-60°C |

| Warm up time | 10-15min |

| Power Consumption | 0.8~1.0kw/h |

| Power consumption | 2500w |

| Laminating mode | Manual |

| Pressure adjustable mode | Pneumatic/non-noise air compressor |

| Input Frequency | 50-60 hz |

| Rated input voltage | 220v(110v-optional) |

| Gross weight of machine | 880KGS |

| Package Material: | Plywood case with steels around for protection |

| Warranty | Broken parts changed for free within one year |

Features

> LED table lighting system

> Tension Media feed shafts

> Heat assisted roller

> Solid steel chassis

> Built in silent air compressor

> Side media roll holders

Advantages

> Reduce production time dramatically

> Consistent high quality work flow

> Time savings equals more profit

> Ergonomically designed, easy to use

> Only minimal training required to operate

Option

Option 1

Name: Transparent cutting mats

Brand: FAYON

Original: China

Protect the table from damage, with a certain self-healing ability.

Option 2

Name: Side Pocket Media Holder

Brand: FAYON

Original: China

Put it inside the machine side pocket or the end of the table, used to load the Rolling Media when Laminating/Mounting the oversize Materials.

Option 3

Name: Tension shafts

Brand: FAYON

Original: China

Loading the materials; Provide resistance when pull the film to avoid over loosing.

Packing

Exhibition

Company profile

HENAN YINGKAI TECHNOLOGY DEVELOPMENT CO., LTD. is a professional manufacturer of laminator machine and paper trimmer for more than 15 years. We are professional in research and design, production, marketing, sales and after-sale service. Our design and research department has more than 5 skilled designer to ensure new product designing and product upgrade, as well as OEM service ability. Our factory has its own CNC machine to do molds. The processing of raw materials is done in our own workshop. We are fully capable of fulfilling OEM orders. Our factory has 2 plants to ensure the productions and delivery. One is roll to roll laminator plant, and the other is flatbed laminator plant. We can fully ensure the production and delivery time. We have strict quality control system from purchase of raw material, producing, assembling to delivery to ensure product quality. Our quality is always good and stable.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in wooden case with foil bag inside.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 7 to 20 workdays after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to our request?

A: Yes, we can produce the machine according to your request.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23