Electronic Wire, Core Wire and Power Wire Insulation Extrusion Production Line (QF-70)

Anhui Boshida CNC Machine Manufacturing Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. QF-70 Engagement System Non-Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Warranty Period 12 Months Heating System Electric Customized Customized Precision Precision Voltage 380V PLC Brand Siemens Inverter Brand Yaskawa Motor Brand Simens Bearing Brand NSK Touch Screen Kunlun Transport Package Shipment or Wooden Box (Required by Yours) Specification CE, SGS, RoHS Trademark SFS Origin Dongguan, Guangdong Provice Production Capacity 30Product Description

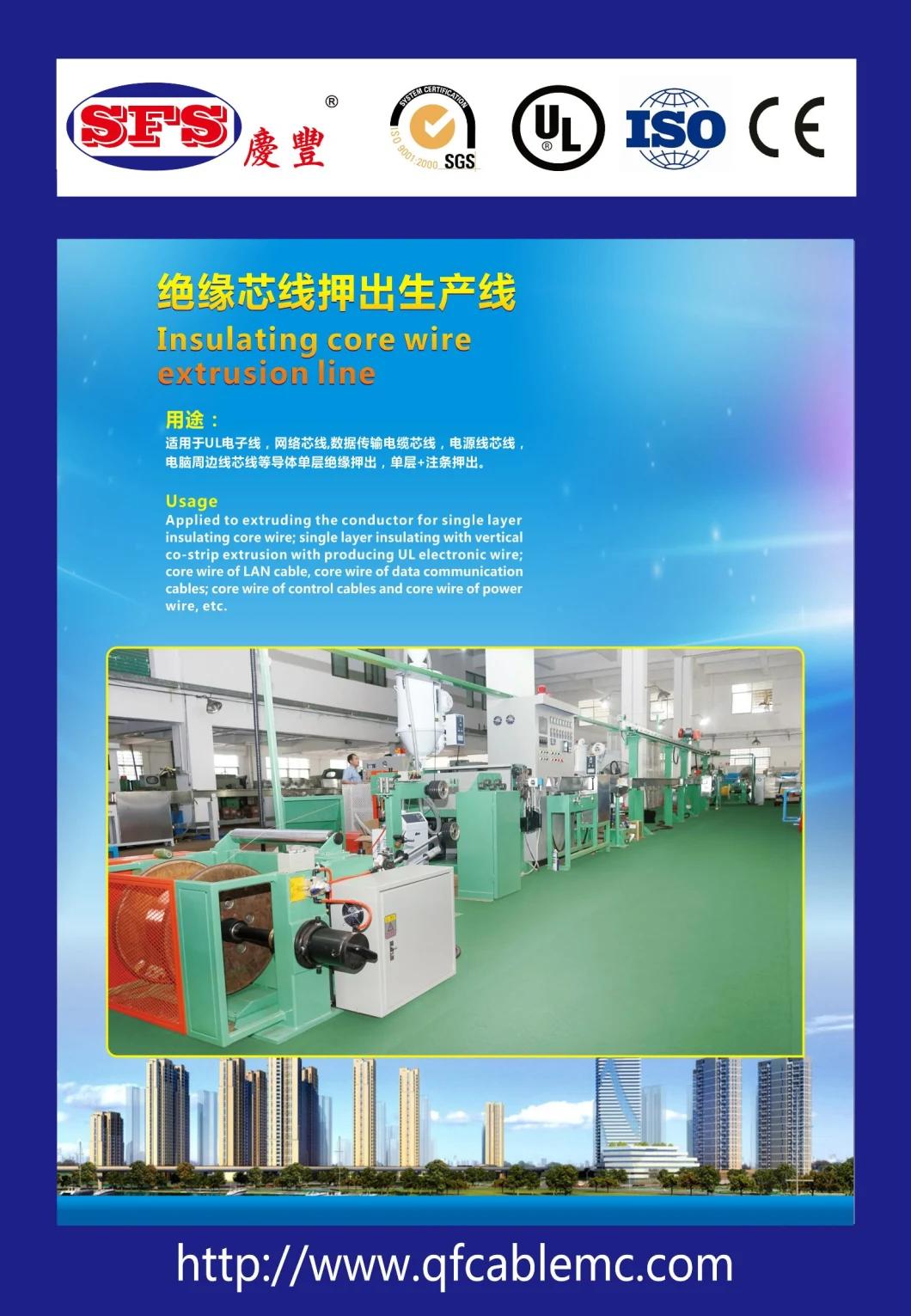

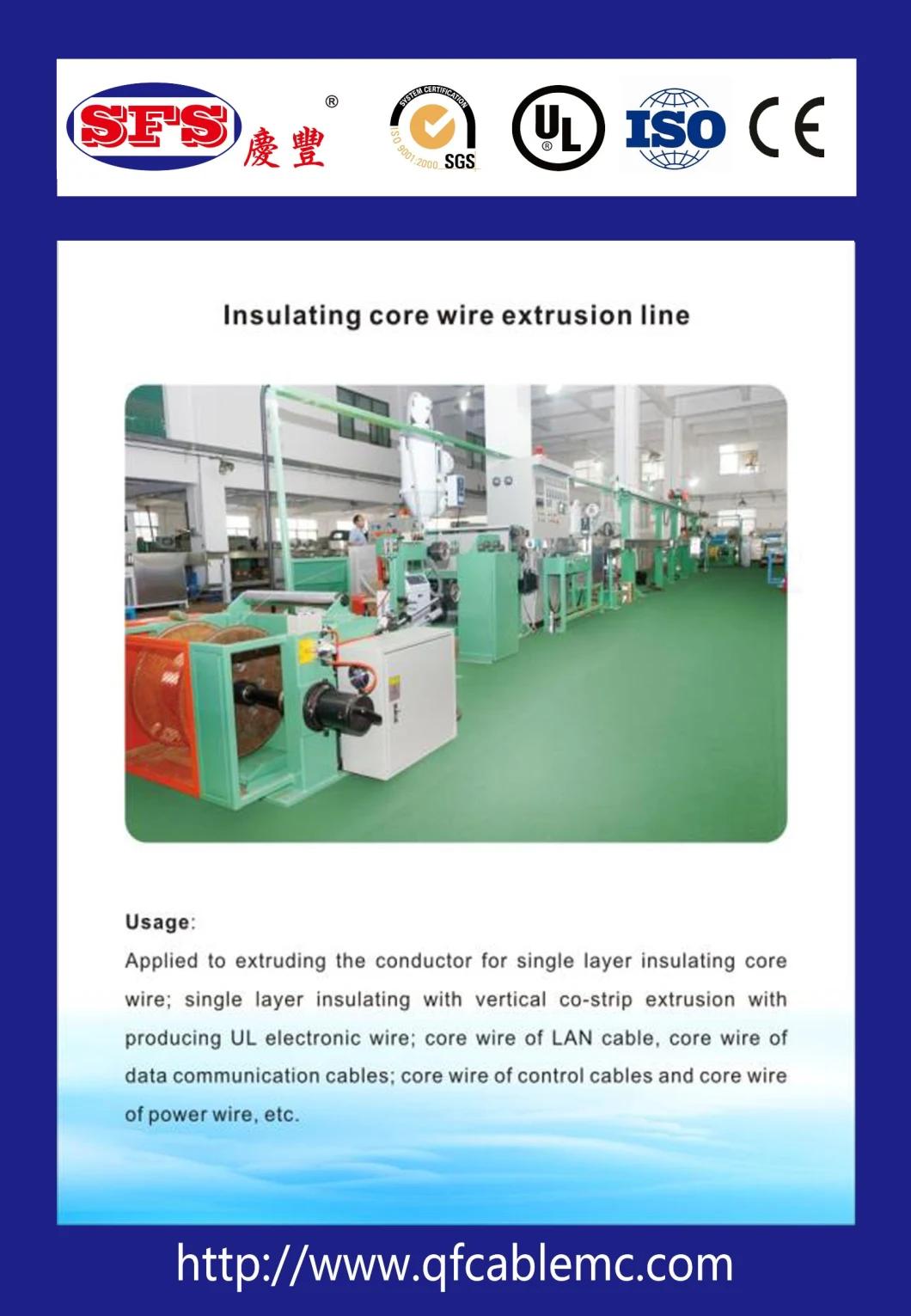

Electronic Wire, Core Wire and Power Wire Insulation Extrusion production line (QF-70)Application

Suitable for single-layer, double color, double layer and three-layer extrusion together of wire and cable using insulated materials such as PVC, PE, LSHF, NYLON, PU, PP and so on.

Structure

It is made up of pay-off stand, tension device, main extruder, main controlling cabinet, cooling tank, capstan, sparkling machine. You can select printer, diameter-testing laser gauge, PLC, caterpillar and non-axis type o f pay-off and take-up.

Technological parameters

Model : QF-70

1. Screw diameter : Φ70mm.

2. Screw L/D : 25:1.

3. Screw speed (Max) : 90rpm.

4. Extrusion output (Max.) : 120kg/hr.

5. Extrusion outlet diameter : Φ1.5mm - Φ12mm.

6. Line speed (Max.) : 400m/min.

7. Pay-off type : Gantry type motor driver

8. Pay-off bobbin diameter : Φ500mm.

9. Main motor : 55kw.

10. Auto-feeding (Max.) : 75kg.

11. OD control : ±0.01mm.

12. Temperture control : ±1°C.

13. Cooling water trough : "U" type sigle layer trough.

14. Capstan power : 5.5kw.

15. Accumulate length (Max.) : 250m.

16. Take-up bobbin diameter : Φ400mm - Φ630mm

Machine feature

Used widely :

Used to conductor single layer/single-layer + striping insulation extrusion.

High output :

Optimizing screw design, screw durable, non cohesive gel, non take-off a chrome, color change quickly, high wire speed, high output.

High quality :

1. Extrusion concentricity : over 93%; Outlet diameter : +/- 0.005mm.

2. The production line was equipped with detecting system, auto-control feedback system, precise diameter and capacitance detecting feedback unit, entirely process control wire or cable insulation diameter and eccentricity parameter to insure the technological requirements.

Temperature control precise :

adopted SCR power control machine with imported high quality temperature control table, the machine temperature controlled with +/- 1ºC.

Easy control :

1. Intelligent control, wire diameter auto-feedback and adjustment, hommization machine design, combined with industrial computer and touch sceen. Making machine operation more easier and convenient.

2. Using PLC controller, professional data control software, industrial computer control and storage display. It can modify technological parameters adjustable and monitor state of extrusion line.

Save place :

Combined traditional accumulate, capstan, take-up and meter counter and so on. Layout is compact.

About our company

Qingfeng electrical machinery factory was found in 2000. It is located in Dongguan city, China. It is an enterprise which devotes to equipment technology research and design and manufacturing. Mainly engaged in various wire, cable and optical cable equipment research, development and bulk production. We mainly manufacture various extruding lines, twisting machines and other peripheral equipments such as physical and chemical foaming extruding production lines, cage-type twisting machine, high speed double twisting machine, back twisting machine and coiling machine and so no.

International market

USA, Italy, Korea, Vietnam, Thailand, Indonesia, Turkey, Iraq, Japan etc.

Cooperative partner

America Tyco and Belden, Madison, Japanese Mitsubishi etc.

Customer service

1. We provide installation knowledge, machine testing knowlege and training operator freely.

2. We track maintenance service regularly for solving the problems in practice.

3. We provide the lifelong parts and technical support for our customer all the time.

4. We provide an all-rounded solution to wiring harness processing area for customer.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23