Mini soya, palm, sunflower, peanut, sunflower vegetable oil refinery

HANGZHOU PROSPERITY IMP. & EXP. CO., LTD. / 2022-07-05

- Type:oil refinery

- Application:cooking oil

- Voltage:380V

- Appearance:Horizontal

- Press Materials:Oil Refinery

- Press Series:Fifth

=== Base Info ===

- Model NO.:JLX

- Condition:New

- Customized:Customized

- Capacity:3T,D

- Raw Material:All kinds of crude oil

- CE,SGS:YES

- English Manual:YES

- Transport Package:wooden box

- Specification:18*6*6m

- Trademark:VIC

- Origin:China

- Production Capacity:1000SET,YEAR

=== Description ===

Basic Info.

Model NO. JLX Condition New Customized Customized Capacity 3T/D Raw Material All kinds of crude oil CE,SGS YES English Manual YES Transport Package wooden box Specification 18*6*6m Trademark VIC Origin China Production Capacity 1000SET/YEARProduct Description

Oil refinery plant

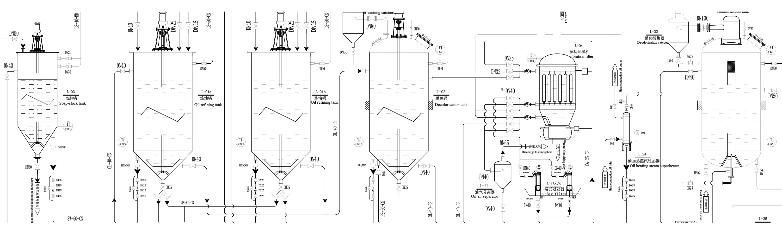

Craft flow sheet for refining workshop

water phosphoric acid caustic soda bleaching clay

Crude oil -----→ water washing--------------------→ degumming -------------→ deacidfication---→drying--------→

steam

decolorization-------→ deodorization -----→ finished oil

Main machine list:

| No. | Name | Qty |

| 1 | Decolorizer | 1 |

| 2 | Leaf vibrating filter | 1 |

| 4 | Steam superheater | 1 |

| 5 | Safety filter | 2 |

| 6 | Deordorizer | 1 |

| 7 | Fatty acid collector | 1 |

| 8 | Cooler | 1 |

| 9 | Polishing filter | 2 |

Introduction of main equipment:

Neutralization pot: For acid refining, alkali refining and water washing.

Decolorization pot: Bleach oil and remove pigment.

Deodorization pot: Remove odor of oil(Made of stainless steel).

Heat conduction oil furnace: Provide heat energy for production,the temperature can reach 280°C.

Vacuum pump: Provide vacuum degree for decolorization and deodorization,up to above 755mgHg.

Air compressor: Dry decolorization bleaching clay.

Filter press: Filter bleaching clay.

Steam generator: Provide steam for deodorization & distillation

Specification: 3T/D

General description of main machines

1.Refinery vessel---------Used to neutralizing, and water washing, to rid off the acid.

2.Decoloring vessel---------Used to get rid of the oil color

3.Deodorizing vessel-------Used to get rid off the smell of oil.

4.Boiler-----It's used to supply for the heats required to the line, it could make the temperature up to 280 degrees.

5.Steam separator-----Separate the steams to oil refiner, decolorer, deodorizer, hot water tank, etc.

6.Press filter---------Used to filter the the decolored oil.

7.Water pump-----Used to pump cool water into water tank.

More pictures

We can do the complete oil production plant processing from Pre-pressing workshop to Solvent extraction workshop to Oil refinery workshop to Final oil bottling workshop. The raw materials are sunflower seeds, soybean, rapeseeds, olive, palm kernal, coconut, jatropha, cottonseeds, rice bran, corn embyro etc.

All the equipment we design, delivery, export, installation and after sale service whole life.

The whole turn key project processing capacity we can do from 1T/D to 500T/D, pls inform us the raw mateirals and processing capacity when inquiry, we can offer the whole project accordingly.

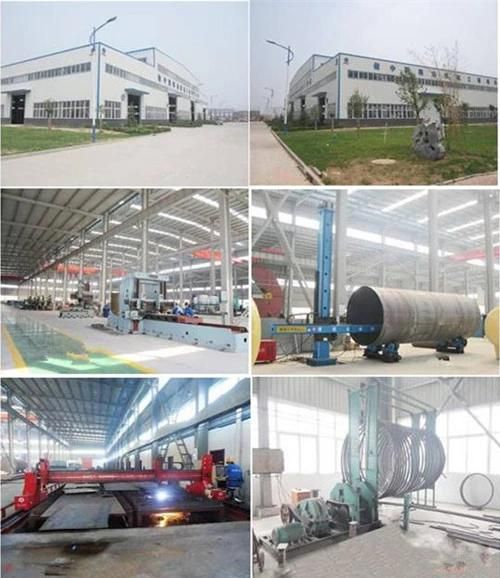

Factory view

Company certification

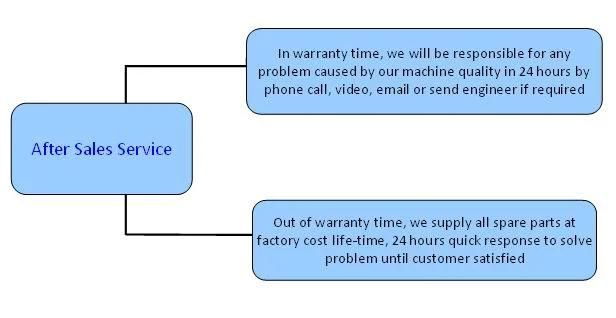

After sale service

Contacts

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23