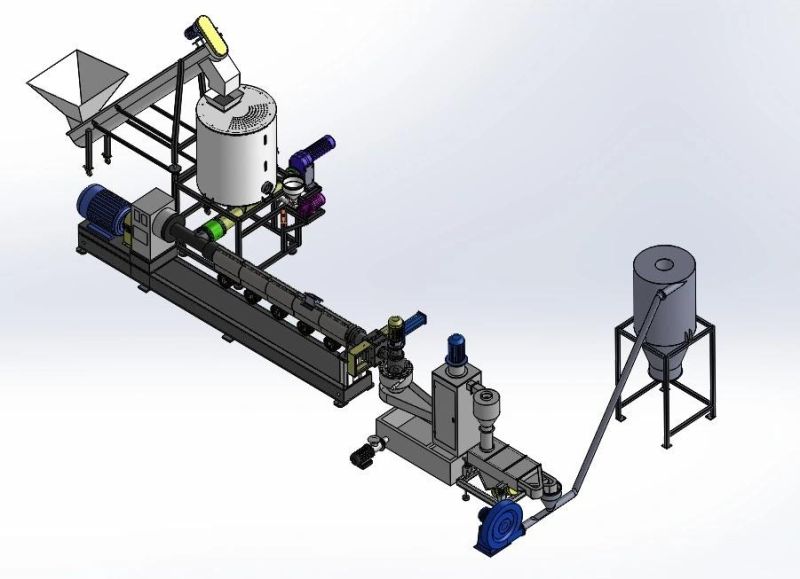

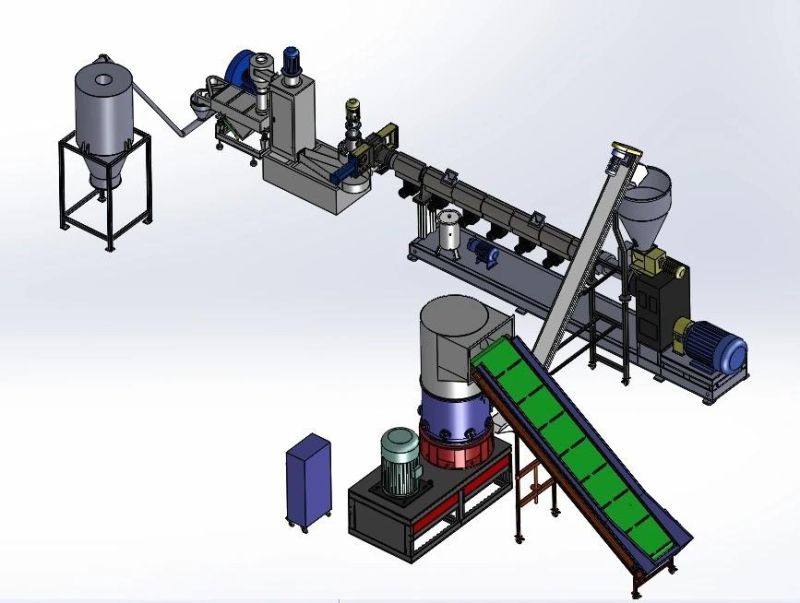

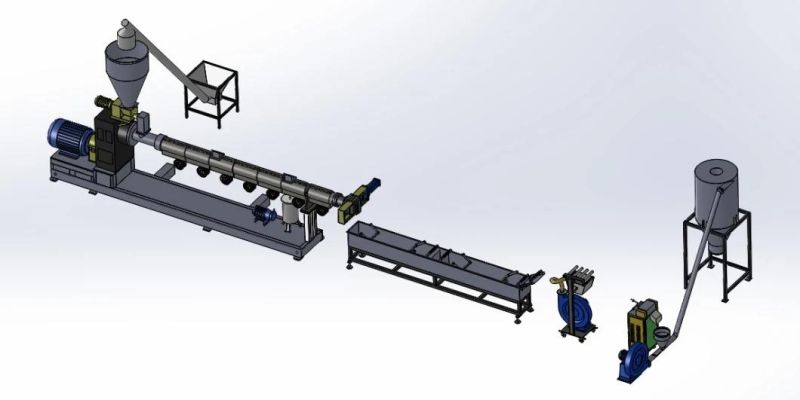

Single Screw PP PE Granulator Machine

Taizhou Shangzheng Hydraulic Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. BDX-D Customized Customized Certification CE, ISO9001:2008 Condition New Motor Siemens Electric Elements Siemens Stage Double Degassing Two Quality Good Material PP PE Film Transport Package Seaworthy Packing Specification CE ISO Trademark Sevenstars Origin Zhangjiagang Jiangsu China HS Code 84778000 Production Capacity 50 Sets/YearProduct Description

Side force feeder pelletizing machine PE PP plastic film

Side force feeder pelletizing machine PE PP plastic filmPE PP Plastic film granulator / waste film pelletizing machine

1. Capacity: 60kg/h-1000kg/h

2. Type: Water-ring pelletizing and stand type

Usage:

This water-cooling single screw plastic pellet making machine is one stage plastic regenerative pelletizer, which is suitable for many kinds plastic waste materials recycling and making pellet, such as PP, HDPE, LDPE, LLDPE Film and clean woven/nonwoven bag materials, etc. The film can be pressed in compressor and then be pelleted.

And also has very developed design, makes sure this machine has a long working life and economical efficiency in using.

Characteristic:

1. Screw and barrel are made of 38CrMoAlA, inlet mouth treated with special alloy: Very strong and long life.

2. Easy operation: It has automatic constant temperature control and stable performance. After adjusting well, 1 or 2 workers are enough to run this machine, to feed the materials and change pellet receiver.

3. Low cost in using after redesign: Now this kind machine is more economic in electric power source and also water. In the long working life of this machine, it can save many sources in energy!

4. High output, long operating life and lower noise: It's the ideal waste plastics regenerative pelletizer machine for nowadays.

The process flow of PE pelletizing line as following: ---watering cutter

Screw feeder →Side force feeder→ SJ120/25 Extruding system →High speed screen exchanging and die head→ Water pelletizing machine→ Dewater machine→ Vibrator sieve → air blower system → Silo

The process flow of PP/PE pelletizing line as following: --noodle cutter

Screw feeder →Side force feeder →Extruding system →High speed screen exchanger and die-head → Water cooling tank → Air blower → Cutter →Vibrating sieve→ Air blower system→ Storage

Model | Diameter | L/D | Screw rotary | Motor Power | Torque | Capacity |

| TSE-20B | 22mm | 32-44 | 600r/min | 5.5kw | 43 | 0.5-10 kg/h |

| TSE-30B | 31mm | 32-48 | 600r/min | 15kw | 119 | 5-30kg/h |

| TSE-40B | 41mm | 32-52 | 600r/min | 30kw | 239 | 90-150kg/h |

| TSE-52B | 51.5mm | 32-56 | 600r/min | 55kw | 438 | 225-300kg/ |

| TSE-65B | 62.4mm | 32-60 | 600r/min | 90kw | 716 | 200-300kg/h |

| TSE-75A | 71mm | 32-64 | 600r/min | 110kw | 1050 | 250-350kg/h |

| TSE-75B | 71mm | 32-64 | 600r/min | 132kw | 1050 | 300-600kg/h |

| TSE-75C | 71mm | 32-64 | 600r/min | 160kw | 1990 | 500-1000kg/h |

| TSE-95B | 93mm | 32-64 | 600r/min | 250kw | 2387 | 800-1200kg/h |

| TSE-95C | 93mm | 32-64 | 600r/min | 315kw | 2506 | 900-1300kg/h |

| TSE-120B | 133mm | 32-64 | 600r/min | 550kw | 7162 | 1500-2250kg/h |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23