Fully Automatic Milk Separator Machine In Dairy Industry

Anhui Decheng Paper Co., Ltd. / 2022-07-05

- Process:Mild Processing

- Power Source:Electric

- Certification:CE, SGS,TUV

- Automatic Grade:Automatic

- Application:Milk, Cheese, butter,casein and ect.

- Customized:Customized

=== Base Info ===

- Model NO.:HT-TZJ5B

- Material:Stainless Steels

- Bowl inner:200mm

- Bowl speed:7546r,min

- Product:500L,H

- Separate factor:8120

- Sludge:PLC

- Power:1.5kw

- Weight:120kg

- Voltage:380V

- Transport Package:Fumigation-Free Wooden Case

- Specification:700*550*800mm

- Trademark:HENTO

- Origin:Henan, China

- Production Capacity:400sets,Month

=== Description ===

Basic Info.

Model NO. HT-TZJ5B Material Stainless Steels Bowl inner 200mm Bowl speed 7546r/min Product 500L/H Separate factor 8120 Sludge PLC Power 1.5kw Weight 120kg Voltage 380V Transport Package Fumigation-Free Wooden Case Specification 700*550*800mm Trademark HENTO Origin Henan, China Production Capacity 400sets/MonthProduct Description

Fully Automatic Milk Separator Machine In Dairy Industry1.Machine Introduction:

The milk cream separator is the most important equipment in dairy industry. Mainly used in the skim milk, butter, casein, cheese production, anhydrous butter production process, removing cream and foreign impurities in the milk. Similar materials can also be used for clarification and purification, such as coconut milk, fish oil, lemon oil.

This product absorbs the advantage of the same kind foreign .Product in Germany and Russia. All the parts that may contact the feedstock are made of stainless steel. Available reduce the chemical effect of the feedstock and the machine spare parts.

Power drive adopts the friction clutch, Transfer power by the fluid, start reliably, prevent overland. The bearings are SKF grade in Sweden, guarantee working precision of the machine.

The separator adopts the PLC automatic control system, can carry out automatic de-slugging, ability of fitness is stronger, automatic degree is high. Easy to adjust, worker labor strength is opposite to ease, the solids content ratio in the mixture fluid is widely.

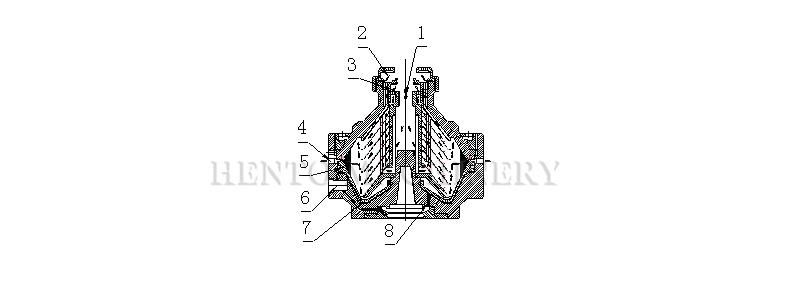

When working, the sealing water 8 is bumped into the sealing room 7, rising the sliding piston 5,and sediment ejection hole 4 is shut down, then milk to be processed are fed to the bowl from feeding pipe 1, Under he effects of centrifugal force, the solids which has heavier density is collected on the bowl wall, After a while, the opening water 8 is bumped into the opening room 6, falling the sliding piston 5,open the sediment ejection hole 4, impurities are de-sludged from the bowl. The lighter liquid (cream) flow along the inner side of the discs into the passage in the upper distributor, the lighter product is discharged from the machine by the lower.centripetal pump 3.The heavier liquid(skim milk) flow along another passage, discharged from the machine by the upper centripetal pump 2.Thus the milk is separated well. The separator adopts self de-slugging and centripetal pump. Thus the machine can work continuously for a long time, attain good separation effects in.

2.Technical Parameters:

| Model | HT-TZJ5B |

| Bowl inner | 200mm |

| Bowl speed | 7546r/min |

| Product | 500L/H |

| Separate factor | 8120 |

| Fat output | Centripetal pump |

| Skim milk output | Centripetal pump |

| Sludge | PLC |

| Power | 380v/1.5kw |

| Temperature | 35-55 ºC |

| Fat in skim milk | 0.03-0.08% |

| Weight | 120kg |

| Dimension | 700*550*800mm |

4.Packing&Delivery:

5.Our Customers:

6.Contact us:

If you need further information, please contact us freely, we will do our best to cooperate with you.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23