Good Effect Pipe Bundle Dryer Maize Flour Drying Making Machine

SHANDONG ONETER IMPORT EXPORT CO., LTD / 2022-07-05

- Warranty:12 Months

- Type:Starch Drying Machine

- Application:Flour, Starch

- Voltage:220V

- Appearance:Vertical

- Press Materials:Corn

=== Base Info ===

- Model NO.:GZG60 GZG100 GZG150 GZG300

- Press Series:Second

- Condition:New

- Customized:Customized

- Machine:Corn Starch Slurry Fiber Separator Machine

- Line:Corn Starch Production Line

- Useful Life:20 Years

- Operation:Automatic

- Energy:Electric

- Service:Overseas Installation

- Price:Negotiable

- Material:Stainless Steel

- Power:5.5 Kw

- Weight:9000 Kg

- Product Name:Pipe Bundle Dryer

- Dimension:6100*1600*2160 mm

- Transport Package:Wooden Case

- Specification:Stainless Steel

- Trademark:JINGHUA

- Origin:Zhengzhou City, China

- Production Capacity:20 Sets,Month

=== Description ===

Basic Info.

Model NO. GZG60 GZG100 GZG150 GZG300 Press Series Second Condition New Customized Customized Machine Corn Starch Slurry Fiber Separator Machine Line Corn Starch Production Line Useful Life 20 Years Operation Automatic Energy Electric Service Overseas Installation Price Negotiable Material Stainless Steel Power 5.5 Kw Weight 9000 Kg Product Name Pipe Bundle Dryer Dimension 6100*1600*2160 mm Transport Package Wooden Case Specification Stainless Steel Trademark JINGHUA Origin Zhengzhou City, China Production Capacity 20 Sets/MonthProduct Description

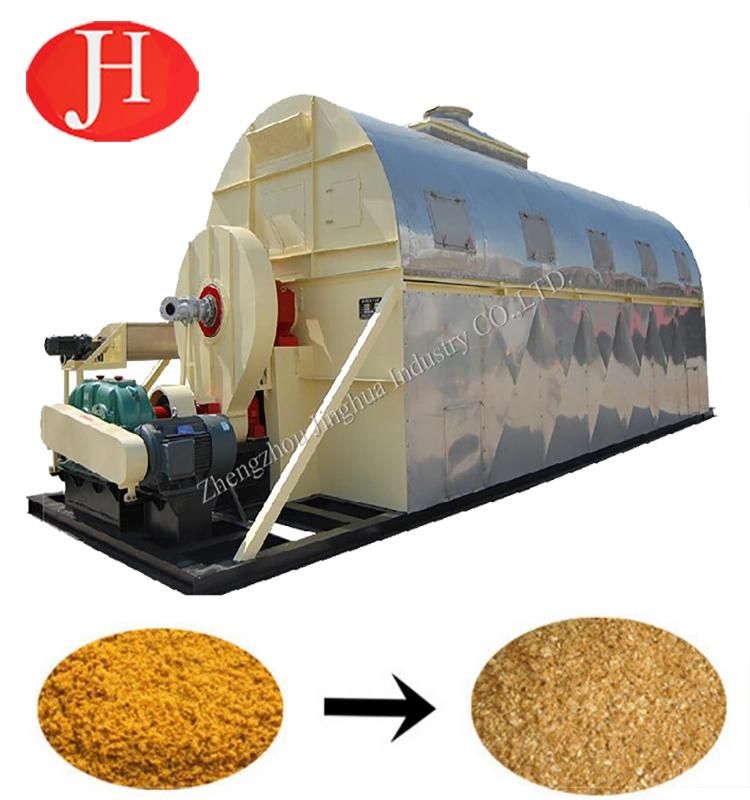

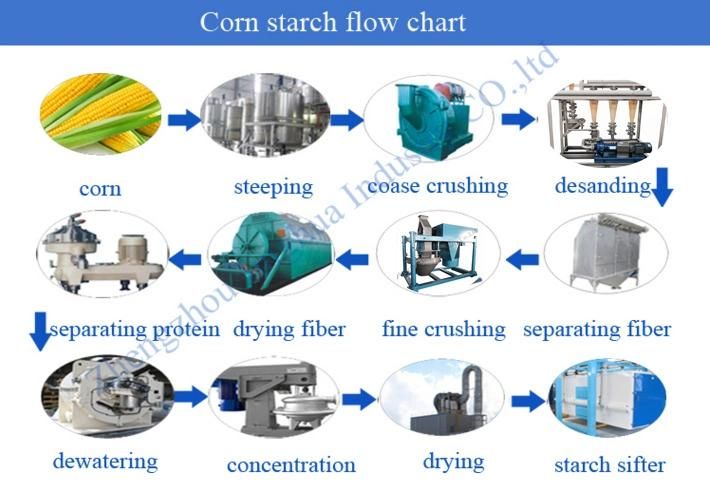

corn starch equipment good effect pipe bundle dryer maize flour drying making machine1.Description of corn starch drying machine

Pipe bundle dryer is widely used in starch industry for drying germ, fiber, gluten. It is widely used in corn production line.

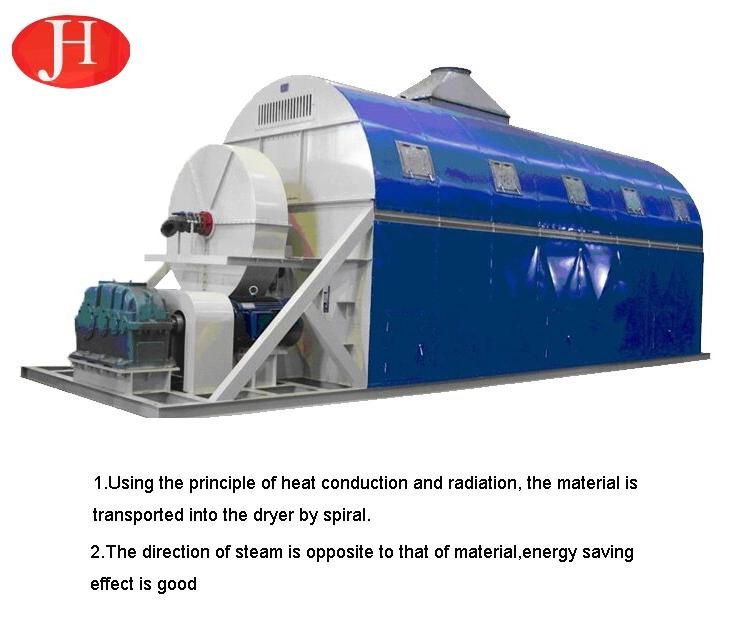

Working principle

Using the principle of heat conduction and radiation, the material is transported into the dryer by screw.Under the agitation of rotating tube bundle copying plate, it moves from the feeding end to the feeding end, and absorbs heat and loses water during the movement. The dryer is in a negative pressure state during production.The steam direction is opposite to the material direction, the energy saving effect is good, in the starch industry used for drying germ, fiber, gluten.

| Materials | Germ | Corn fiber | Corn protein |

| Inlet water content | 55% | 60% | 45% |

| Outlet water content | 3~5% | 10~12% | 12~13% |

| Drying intensity (evaporation kg water/ m2) | 2.5~3 | 4.8 | 4.7 |

| Model | Outline dimension | power(kw) | Weight (T) |

| GZG60 | 6100*1600*2160 | 5.5 | 9 |

| GZG100 | 7800*1900*2460 | 7.5 | 13.5 |

| GZG150 | 7100*2200*2750 | 11 | 19.5 |

| GZG300 | 8800*2460*3180 | 18.5 | 26.5 |

| GZG500 | 10980*2900*4000 | 37 | 50 |

| GZG650 | 11190*3200*4300 | 55 | 67 |

| GZG1000 | 11800*3660*4770 | 110 | 91 |

3.Company Information

Jinghua company is an engineering and technical company specializing in starch engineering design, equipment manufacturing, engineering installation and debugging, techncal personnel training and other work. Has two modern large factory, engineering and technical personnel more than 30 people, can provide installation services overseas .Company for China starch industry association executive director units, executive director of the association of Chinese cassava starch industry unit.

Mr. Wang yanbo, chairman of the board, has published 7 scientific works, 6 national standards and 30 academic papers, across a country: "ten five" to "thirteen, five" national key r&d projects and provincial major research project over 10, with more than 10 national patents, won awards at all levels more than 20. Has participated in more than 80 domestic and foreign starch engineering design work, its advanced processing technology and technology has reached the world's leading level.

3.our Service

Pre-sale service

1.Introducing detail features and application of the products to customer.

2.Selecting economical and practical machines for customer.

3.Providing operation data of the related machine.

4.Providing means of trial performance for customer.

5.Flow chart and factory designing layout .

Sale service

1.Recommending engineering conditions required for installation of the machine.

2.Communicating the manufacturing progress of machines with customer in time.

3.Project planning and design services.

After-sale service

1.Training of equipment maintenance and operating personally.

2.Installation and commissioning of equipment until everything is functional.

3.One year warranty and providing long-term maintenance service and spare parts.

4.Giving technical support to customer for developing new product.

5.Engineers available to serve machinery overseas.

4.Packing & Shipping

Packing & Shipping: Customize the wooden case according to the size of the product.

Delivery: 14 days after receiving pre-payment (on time according to contract strictly).

5.FAQ

Q1: Is your company a factory or trading company?

A: Our company is a factory in Henan Province ,with export license and we have done export business over 20 years professionally.

Q2.What is your main business?

A: Zhengzhou Jinghua is devoted to starch processing machine. The machine of starch processing line , such as : cassava starch line , cassava flour line , potato starch line , sweet potato line , wheat starch ,sago line and garri line

Q3. Can you customize the products according to our requirements?

A: Yes, we have a professional technical department that can customize the products according to your requirements

Q4: Are your products can be assured ?

A: Our machines are all passed ISO9001:2001 and have CE certificate by SGS, TUV.

Q5: If we show you our layout of factory, can you help us to design the whole process line?

A : Yes, our experienced engineers and technical employees can help you to arrange the layout and installation of whole process line based on your real situation;

Q6: If we have samples of new products, can you help us to analysis and design the machine?

A: Yes, Our technical department can help you to analysis, design and test the new products you offered.

Zhengzhou Jinghua Industry Co.,Ltd.

Add:Guanggu Road, Xingyang City,Henan Province,China

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23