Plastic Plate Profile Pipe Extrusion Extruder Machine Line for Wood Plastic Door Frame ...

Hubei St. Bairui Diamond Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. BRD Customized Customized Condition New Extruder Type Double Screw Extruder Transport Package Wood Pallet and PE Film Specification ISO9001 Trademark BEIER MACHINERY Origin China HS Code 84772090Product Description

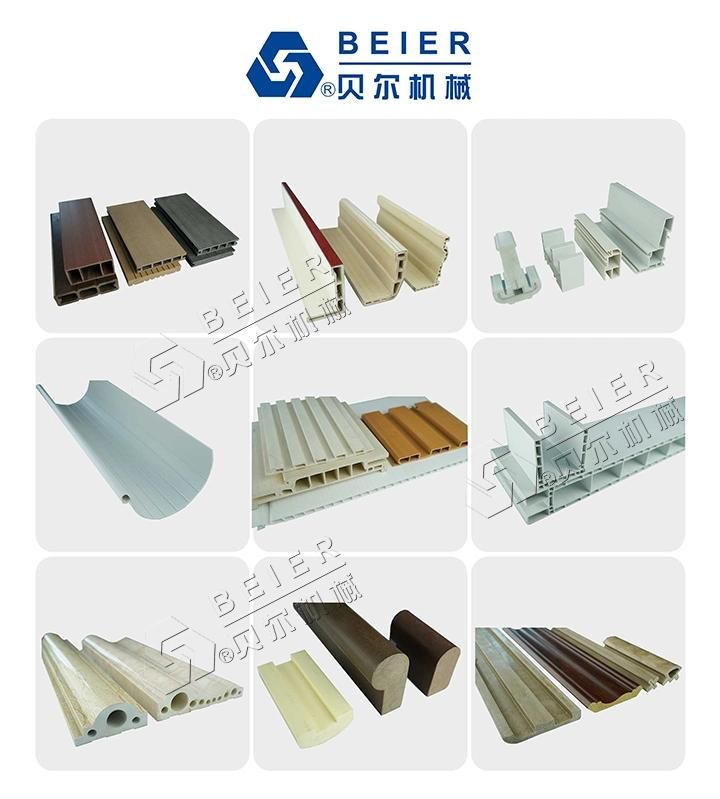

Plastic Plate Profile Pipe Extrusion Extruder Machine Line for Wood Plastic Door Frame Flooring

Introduction of the PVC window profile extrusion line:

PVC window profile extrusion line consist of twin screw extruder, vacuum shaping table, drawing machine, plastic cutter and pilling frame, and also coordinated with different profile break-section and mould to produce PVC door and window profiles, foamed special shaped materials, decoration panel material, profile and multi-hole wire plastic products.

The door and windows profile is made of PVC powder. It is widely used as window and door profile, as well as decorative material. With modern technology and optimized design, it has the property of high output capacity, long life and plastic evently.

This PVC window profile extrusion line is designed for extrusion of PVC plastic door's and window's profiles and cross-section communication cable pipes, Aluminum-plastic composite profiles, etc. It has stable plastification, high output, low sheering force, long life service and other advantages. PVC profiles can be used in the building industry and home or office.

Production Flow:

Material →Heating Cooling Mixer →Material Feeding →Conical Twin Screw Extruder →Extrusion Mould & calibrator → Cooling →Printer → Haul-off Unit →cutter →stacker

Equipment Features:

For extruder Temperature Control system,Digital PLC control or Manual Temperature Control Meter

Easy Operation,Reliable performance,High Extrusion Efficiency,Easy Maintenance

Work flow and detailed configuration:

| Feeder | • To feed material into extruder; |

| Extruder | •World famous brand electrical component: Siemens, Schneider, ABB etc; • High torque gearbox with adopts NSK/SKF bearing; • Siemens/WEG original motor achieved global after service; • Bimetallic screw and barrel; • Intelligent PLC controlling system with human-friendly interface. |

| Die head | • 3Cr13/3Cr17 material • Complete set include extrusion die head, calibrator and cooling tank • Adopt to single, co-extrusion, foam imitation marble profile |

| Calibration table | • Include full set of vacuum and water pump • Width: 240mm • Length: 6000mm • Independent operation panel for easy operation |

| Haul off | • Upper/lower caterpillar driven separately and speed control by inverter • Fast change type pads for easy operation • Install plate is adopts aluminum material |

| Cutter | • Lifting saw cutter with adopts double station dust collection system •Synchronous drivingby air cylinder or servo motor control |

| Stacker | • Stainless steel304 as touching material • Discharge driving by air cylinder |

| Hot stamping machine | • Decorative pattern and film protection of product surface |

Trade Terms

- Payment Term: 30% for prepayment by T/T, 70% for balanced payment by T/T, or L/C can be acceptable

- Delivery Time: 40 days after receipt of prepayment.

- Packing Method: Packing film or wooden case

- Guaranteed Time: 12 months

- When machine finished, we will invited client come to our factory to check the machine and do the machine test. If machine is ok, then client pay for the balance. And inspect machine load the container.

- When machine arrives client's factory, if client needs, we will send 1-2 engineer to client's factory do the machine installation and running test, and also train the local worker how to operate and maintain the machine. It is chargeable.

- If have any question or problem on machine operation or maintain, welcome to contact to us by email or calling. We stand by 24 hours.

- Payment Term: 30% for prepayment by T/T, 70% for balanced payment by T/T, or L/C can be acceptable

Pre-Sale and After-Sale Service:

1. Provide all the machines for the complete production according to customer's requirements.

2. Provide complete service for factory layout and other information to help customer to build the factory.

3. Provide the raw material to the customer if need.

4. Provide good service for machine installation and training, until the customers can run the machines and make stable production.

5. Provide after-sell service for all the life, except one year quality guarantee,

6. Provide good quality, good price and good service to customer. We are the professional and trustable supplier for turnkey projects. Let us do win-win business together.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23