Ws The Latest Technology Industrial Milk Homogenizer Mixer Machine

Guangdong Yincai Science & Technology Co., Ltd. / 2022-07-05

- After-sales Service:Online Support, Video Technical Support

- Warranty:1 Year

- Process:Mild Processing

- Power Source:Steam

- Certification:ISO9001

- Automatic Grade:Manual

=== Base Info ===

- Model NO.:WS-25-1

- Application:Milk, Yogurt, Ice Cream

- Customized:Customized

- Processing Types:Milk, Juice, Ice Cream, Yogurt

- Product Name:Homogenizer

- Flow:1000L,H

- Maximum Pressure:25MPa

- Normal Pressure:≤20MPa

- Temperature:≤80ºC

- Material:SUS304

- Stage:Two Stages Homogenization

- Inlet of Material:Ф33mm

- Transport Package:Wooden Box,Case

- Specification:1150*450*1100mm

- Trademark:WS

- Origin:Shanghai

- Production Capacity:100sets,Year

=== Description ===

Basic Info.

Model NO. WS-25-1 Application Milk, Yogurt, Ice Cream Customized Customized Processing Types Milk, Juice, Ice Cream, Yogurt Product Name Homogenizer Flow 1000L/H Maximum Pressure 25MPa Normal Pressure ≤20MPa Temperature ≤80ºC Material SUS304 Stage Two Stages Homogenization Inlet of Material Ф33mm Transport Package Wooden Box/Case Specification 1150*450*1100mm Trademark WS Origin Shanghai Production Capacity 100sets/YearProduct Description

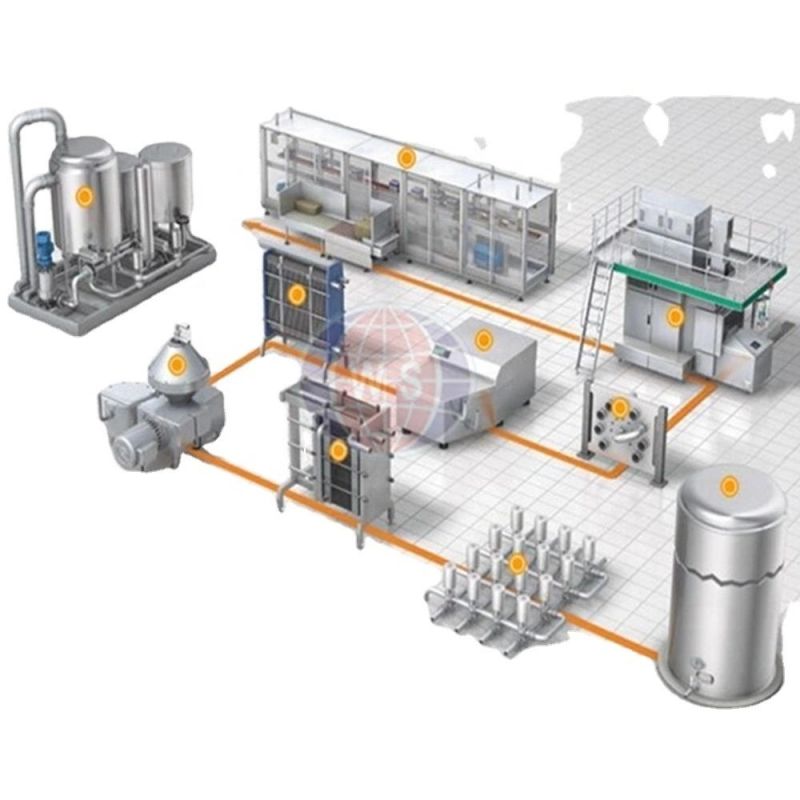

I.Product Description:

Working principle:

1. The homogenizer is a kind of ultra-fine comminution, emulsifying homogenate equipment.

2. It's USES high pressure conditions suspension liquid, through an adjustable homogeneous valve aperture

voltage-absent, expansion, explosion, shear and collision, comprehensive effect material to superfine crushing,

particle size can reach 0.01 ~ 2 u m, average 1 muon m, and formed a good emulsion or dispersed.

Description of Construction:

1) Actuation: Two-step of speed changes; first step is belt pulley; the second step with crank gears get transmission

oppositely; the slide can be disassembled simply, spindle and tile are made of special alloys, the rolled axletree

setted on two sides make the machine steadily and low noise.

2)lubrication: Splashed free lubrication.

3)Main pump: Three channels,the pressing cover takes radial direction sealing itself.

4)3Pistons: Quadrate sealing component, code:X4310

5)One-way valve:There are 3 in and out of tapered valve, total 6.

6)Homogenizing valve:The one step ,high pressure component consist of high pressure valve core,

high pressure valve seat and impact ring.The two step,low pressure component consist of two plane valve.

7)Control of pressure:One diaphragmatic pressure gauge imported and assembled from Germany.It control high

pressure and low pressure.

8)Adjustment of pressure: Stepless manual Adjustment for the pressure gauge,two step.

Features:

·Stable operation, low noise, convenient cleaning, flexible maneuverability, continuous use, superfine dispersion and

emulsification of materials. It can be widely used in the emulsification, homogenization and dispersion of industrial production.

·The material can be refined and mixed under the triple action of extrusion, strong impact and loss of pressure expansion. This equipment is an important equipment for food, dairy, beverage and other industries. · Homogenizing all kinds of dairy beverages such as milk, soymilk, etc. under high pressure can significantly refine the fat globules in the milk liquid, making the products easy to digest and absorb after eating, and improve the value of use. · Used in the production of ice cream and other products, itcan improve the fineness and porosity of the material liquid, and its internal texture is obviously improved. ·Used in the production of emulsions, glues, fruit juices, slurries, etc., it can prevent or reduce the layering of the material and liquid,and improve the appearance of the material and liquid, making it more bright in color, stronger in fragrance, and more mellow intaste.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23