Semi Automatic 3&5 Gallon Pet Bottle Blowing Machine / Bottled Making Machine

Hangzhou Santiway International Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

2.Volume: 20l

3.Weight:650kw

It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle etc.

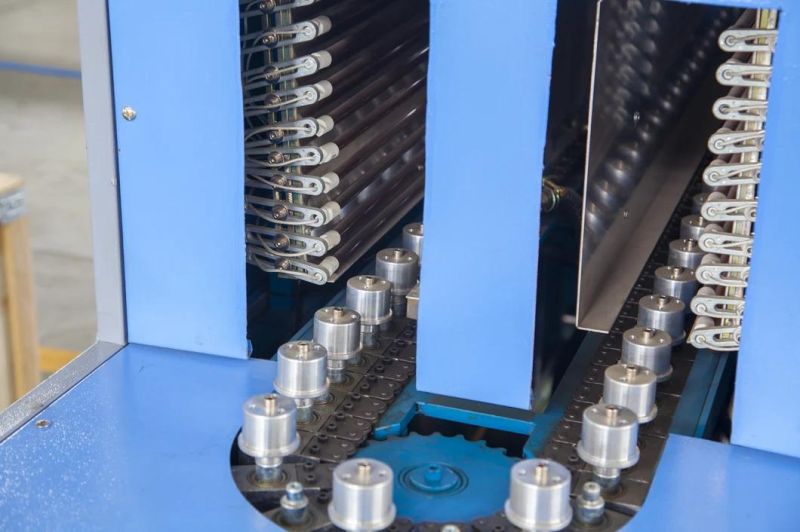

Adopting double crank to adjust mould, heavy locking mould, stable and fast, Adopt infrared oven to heat the perform, the perform rotated and heated equally.

The air system has been divided into two parts: Pneumatic action part and bottle blow part to meet the different requirements for the action and blow. It can provide sufficient and steady high pressure for blowing large irregular shaped bottles.

The machine is also equipped with muffler and oiling system to lubricate the mechanical part of the machine.

The machine can be operated in the step by step mode and the semi-auto mode.

The machine is small with low investment, easy and safe to operate.

| RM-9b Semi-automatic 2-cavity Blowing Machine | |||

| MOLDING | Clamping force | kg | 1300 |

| Clamping stroke | mm | 155 | |

| Stretching stroke | mm | 370 | |

| Bottom Stroke | mm | / | |

| Cavity pitch | mm | 130 | |

| Number of Cavity | Cavities | 2 | |

| CONTAINER | Max.container volume | itr | 3 |

| Neck diameter range | mm | 10-120 | |

| Max.container diameter | mm | 130 | |

| Max.container height | mm | 350 | |

| Carriage unit | pcs | 72 | |

| THEORETICAL OUTPUT | bph | 1200 | |

| ELECTRICAL SYSTEM | Total power | kw | 17 |

| Heating power | kw | 16 | |

| Max.heating power | kw | 8 | |

| AIRSYSTEM | Operating pressure | kg/cm2 | 7 |

| Air consuming | Itr/min | 600 | |

| Blowing pressure | kg/cm2 | 25 | |

| Air consuming | Itr/min | 800 | |

| AIR DRYER | Operating pressure | kg/cm2 | 2~4 |

| Temperature | 10~12 | ||

| Consuming | kcal/hr | 2000 | |

| Flow rate | Itr/min | 30 | |

| WATER CHILLER | Operating pressure | kg/cm2 | 2~4 |

| Temperature | 30 | ||

| Consuming | kcal/hr | 10000 | |

| Flow rate | Itr/min | 130 | |

| MACHINE | Machine size | mm | 1650-650-1700 |

| Machine weight | kg | 600 | |

| REMARKS | 1. All data standard infication for0.6L bottle. 2. The actual output depends on the preform quality and boltte shape. 3. Specifications are subject to change without notice. 4. Please provide the stable ambient temperature. | ||

Hearting Part

Blowing Part

1. How about the bottle size,volume ,height ,neck diameter ,diameter of bottle or other please inform us of details .Pictures and design will be great

2. What is the production capacity(per hour) you want ?

3. Your power supply, for examples : 3Phases AC 380V 50Hz

then we can offer you more detailed quotation and other information you need .

ZHANGJIAGANG RELIABLE MACHINERY CO.,LTD

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23