Huatai Uvo Making Biodiesel Process Biodiesel Used Cooking Oil Biodiesel Machine Oil ...

Shenzhen Xiangfeizhu Technology Co., Ltd. / 2022-07-05

- Type:Bio-Diesel Machine

- Application:Used Cooking Oil

- Voltage:380V

- Appearance:Vertical

- Press Materials:Sesame

- Press Series:Second

=== Base Info ===

- Customized:Customized

- Condition:New

- Transport Package:Suitable for Shipping

- Specification:2100*280*1370mm

- Trademark:HUATAI

- Origin:Henan

- HS Code:84792000

- Production Capacity:30sets,Month

=== Description ===

Basic Info.

Condition New Customized Customized Transport Package Suitable for Shipping Specification 2100*280*1370mm Trademark HUATAI Origin Henan HS Code 84792000 Production Capacity 30sets/MonthProduct Description

Brife Introduction of Huatai Cereals and Oils Machinery Co.,Ltd

Our belief is "Seiko Winning". Henan Huatai Factory covers an area of 100,000m2, of which the workshop covers an area of over 21600 m2. The headquarters is equipped with 8 standard production workshops, 2 machining workshops and 12 engineering installations. Huatai Machinery has 120 sets of various production and processing equipment, including more than 80 lathes, planers, milling machines and drilling machines, more than 10 sets of shearing equipment, 6 automatic welding machines for submerged arc welding, DC welding machines and AC welding machines. Multiple units are also equipped with various auxiliary equipment and testing equipment. Welcome to visit our factory!

Huatai Products list

- 30~1000T/D rice bran expanding pretreatment process,solvent extracting processing equipment

- 30~600T/D Rice bran First-grade oil refining equipment

- Series rice bran molecular distillation refining primary oil complete equipment

- 30~5000T/D Oil pretreatment, pre-pressing, leaching equipment

- 50~1200T/D Grease refining equipment

- 10~2000T/D Corn deep processing equipment

- 10~1200T/D Palm oil, cottonseed oil refining and separation equipment

- 30~1000T/D Biodiesel equipment

- Rice bran oil, cottonseed oil mixed oil refining equipment

The advantages of biodiesel

Biodiesel, also known as fuel methyl ester, is a new type of fuel made from vegetable oil or animal oil processing. Its performance is similar to that of 0# diesel. When using biodiesel, there is no need to improve the structure of existing diesel engines. The characteristics are as follows:

1. Biodiesel is low in sulphur, but emissions of sulphur dioxide and sulfides are reduced by 30%.

2. Better lubrication performance can reduce the wear rate of fuel injection pump, engine cylinder and connecting rod

3. Better starting performance of low temperature reverse motor

4. Biodiesel has a high flash point, is not a dangerous product, is not volatile, and the biodegradation rate is as high as 98%

5. The cetane value of biodiesel is high, and its combustion performance is higher than that of petrochemical diesel

It's a renewable resource

7. High petrochemical efficiency ratio

Huatai Bio diesel technic

Type: high temperature preparation of biodiesel from high acid vegetable oil

Processing Material: vegetable oil, Acidic Oil, Soap-stock, Oil residue, Waste Cooking Oil, Animal Oil

Capacity: 10-500T/D

Major equipment: esterification reactor, distillation column, condenser, reboiler, pressure vessel

Application: biodiesel is a new type replacement fuel from renewable sources

Huatai patent invention of biodiesel production line adopts high efficiency biodiesel technology at high temperature to obtain biological diesel oil as renewable source. This environmental protective and reproductive biodiesel is available under certain temperature, pressure, catalyst, and form fatty acid methyl ester, and through high vacuum distillation and rectification technology with high oil purity.

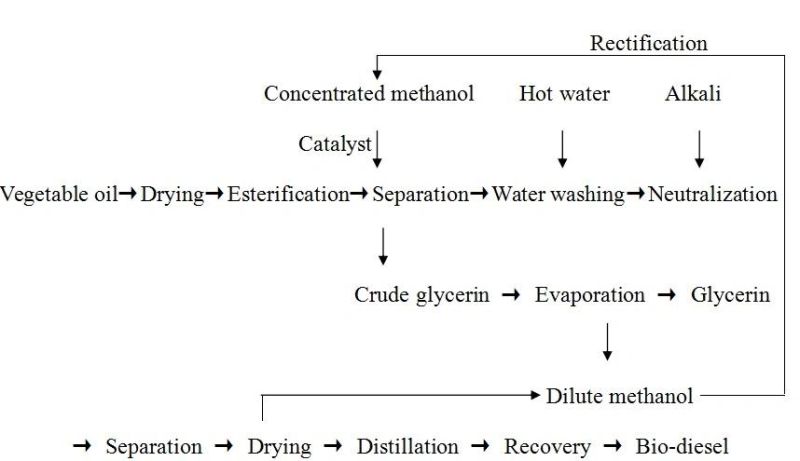

Biodiesel Process flow

Esterification method to make biodiesel

R1 COO CH2

R2 COO CH + 3MeOH( EtOH)--R1 (R2,R3 ) COOMe[ R1 (R2,R3 ) COOEt ] +2CH2 (OH) CH(OH)

R3 COO CH2

Thermal Pyrolysis Method to make biodiesel

R1 COO CH2

R2 COO CH + catalyzer-- CH3(CH2)14CH3 + C3H4O + H2O

R3 COO CH2

Bio-diesel index

| Item | Index |

| Density(at 15ºC)/g/ml | 0.82-0.900 |

| Dynamic viscosity(at 40ºC)/ mm2/s | 1.9-6.0 |

| Flash point/ºC | ≥130 |

| Sulphur content/% | ≥0.005/0.05 |

| Coking value 100%(CCR)/ % | ≤0.05 |

| Cetane value | ≥49 |

| Ash content /% | ≤0.3 |

| Moisture/ppm | ≤0.05% |

| Total impurities/ppm | No mechanical impurities |

| Corrosive nature to copper (Extent of corrosion at 50ºC for 3h) | ≤1 |

| Neutralization value(mgKOH/g) | ≤0.8% acid value |

| Methanol content% | -- |

| Free glycerol % | ≤0.02 |

| Total glycerol % | ≤0.24 |

Biodiesel plants

Biodiesel Plant workshop

Huatai company advanced appliance

Customers all over the world come to visit our Huatai factory

Huatai Machines go to the world

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23