PP Hollow Corrugated Sheet Making Machine for Floor Guard /Printing Hoardings/Package Box

Ningbo Easyget Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJMS120/36 Computerized Computerized Certification CE Customized Customized Condition New Main Extruder Sj120/36 Main Motor Power 75kw/90kw Line Speed 2-6m/Min Capacity 190-250kg/H Appliaction Plastic Package Box, Ad Printing Sheet Transport Package Sea Worth Package Specification 1220mm width, 2-6mm/7-12mm thickness Trademark TONGSAN Origin China HS Code 84772090 Production Capacity 190-250kg/HProduct Description

PP hollow corrugated sheet making machine for floor guard /printing hoardings/package boxThis production line realizes continuous production of PC/PE/PP hollow grid plate, which is applicable to construction decoration, advertisement collocation, and noise insulation of highway as well as packaging. PE/PP hollow grid plate is an ideal substitute for paper box in making packaging box. It is characterized by light weight, high intensity, dampproof, and anticorrosion. The width of the products is 1220-2100mm, and the thickness is 2mm-12mm.| No. | Item | Parameter |

| 1 | Raw material | pp pe pc |

| 2 | Production size | 2600mm |

| 3 | Product speed | 1-6mm/7-12mm |

| 4 | Max.ectruder capacity | 450-600kg |

| 5 | Overall weight | 18 T |

| 6 | Overall dimension size | 30*4*3 |

| 7 | Power | 260kw |

| 8 | Air inflow volume | 0.8m³/min |

| 9 | Pressure | 0.6-0.8mpa |

| 10 | Circular water poor | 30m3 |

| 11 | Electrical condition | 380v/50hz or customized |

Qingdao Tongsan Plastic Machinery co.,;td have been develop the PP hollow corrugated sheet making machine since 2015,now we have the machines for the PP hollow grid plate width from 1220mm to 2450mm and thickness from 1.5mm to 12mm.We have different model production line,such as the 1400 type PP hollow sheet extruder machine,1860 type PP corrugated sheet production line,2300 type PP hollow corrugated board making machine,2600type plastic hollow grid panel making machine,and for each model,we have the co0extrusion type for customer choose.The co-extruder type can use 20%-60% fillermatch for reduce the cost,so our customer can product the cost competitiveness sheet with goog quality.Our machine have the advantage of high output,easy operation,high precision,good products with smooth surface straight rib.

1,Extruder for pp hollow sheet machine:The specially designed screw and the advanced controlling system ensure excellent plasticization,high output and stable extruding.We have the co-extrusion type to use the recycled plastic to reduce the cost with high quality products.

1,Extruder for pp hollow sheet machine:The specially designed screw and the advanced controlling system ensure excellent plasticization,high output and stable extruding.We have the co-extrusion type to use the recycled plastic to reduce the cost with high quality products.2,Co-extruder for the PP hollow sheet machine. the co-extrusion system is used for making AB layer PP hollow sheet.The inner layer can use recycled PP material or High PP filling material.

3,Mould for pp hollow sheet machine: Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips, and also differential action of up-down piece guarantee even thickness of the plate.

4,Screen changer for pp hollow sheet machine : Quick screen changer of hydraulic system ensures the short course of screen changing. Double-position combined with special sealing structure guarantee stable operation of screen changer.

5,Vacuum calibrating table for PP hollow sheet machine: Heating exchanging and cooling system of quick speed in calibrating system alternate effectively and ordinally with vacuum system, which ensures calibrating precision. Vacuum system composes two independent subsystems and each is equipped with several fixed circulating vacuum lines of three-point type. Meanwhile, each line carries vacuum regulating system and vacuum display system that realize even and stable vacuum degree of plate surface.

6,Tractor for PP hollow sheet machine: There are two tractors. The first one is high power, high reduction ratio, multi-roller type, well low-speed operation, high traction and is able to draw the plate up from the calibrating table evenly and synchronal. The second one is designed to remove stress, and in addition it is equipped with edge-cutting device to ensure the valid width and smooth cut of the edges.

7,Stress remover corona treatment device for PP hollow sheet machine:The advanced large area conductive heating mode can effectively remove the stress of plate and further improve planeness of the plate.

8,Auto Cutting machine for PP hollow sheet machine: Accurate instant length-fixed cutting and automatic up-down discharging system combined with alloy steel sharp blade realize high quality of cutting.

9,Differnt width and length cutter (New design )

10,Automatic Manipulator (New design )

Application Of PP Hollow Corrugated Sheet

1, Application of PP Plastic Hollow Corrugated sheet/Plate in Fruit,Vegetable and Food PackagingPP plastic hollow packing box has excellent moisture resistance, water resistance, low temperature resistance, light and high strength, non-toxic, environmentally friendly, recyclable and reusable features, etc.Products: Apple Store Packing Box, Ginger Packing Box, Asparagus Packing Box, Grape Packing Box, Milk Packing Box, Variety Packing Box, Dairy Packing Box, etc. 2, Application of PP Plastic Hollow Corrugated sheet/Plate in Industrial PackagingPP plastic hollow plate is widely used in the field of industrial packaging, because of its light and high strength, good buffer performance, good weather resistance, environmental recyclable reusable.PP plastic hollow plate industrial logistics turnover box product line is very rich, there are double-layer fixed turnover box, single-layer fixed turnover box, single-layer folding turnover box, matching knife card pad, storage cage enclosure, etc. According to the function can be divided into electronic turnover box, auto parts turnover box, logistics turnover box and so on; can meet the logistics turnover needs of all kinds of enterprises. 3, Application of PP Plastic Hollow Corrugated sheet/Plate in Packaging of Glass BottlesWith the continuous improvement of the quality requirements of glass bottles, the traditional packaging of sacks cannot meet the needs of production and market. Tray packaging can overcome the drawbacks of sack packaging, can reduce the packaging and transportation of glass bottles broken, but also to avoid the sack after a long time on the bottle ash and even adhered to the bag of decay.PP plastic hollow plate according to the customer's requirements, sealing edge, sealing angle to produce a variety of high strength and size of glass tray packaging plate. 4, Application of PP Plastic Hollow Corrugated sheet/Plate in Advertising Decoration and Advertising PrintingPP Plastic is dedicated to improving the quality of hollow plate, research and development of plastic hollow plate deep processing. develop different processes according to different products. Made of indoor and outdoor advertising exhibition display board, publicity posters, dairy drinks and wine display box and other products, this product has waterproof and moisture-proof, anti-aging, exquisite printing, long use time, beautiful and generous, overall vision and other characteristics. 5, Application of PP Plastic Hollow Corrugated sheet/Plate in Refrigerator and Washing MachinePP plastic hollow plate is a new type of environmental protection products, no pollution, no harm, meet the requirements of green environmental protection. The product has large internal quality, flat surface, high breaking strength, flame retardant, good moisture-proof performance, zero surface water and steam penetration, heat insulation, good energy saving effect. Especially the refrigerator with external condenser has excellent adiabatic effect. The company can make all kinds of refrigerator, freezer, washing machine back and base according to customer's request

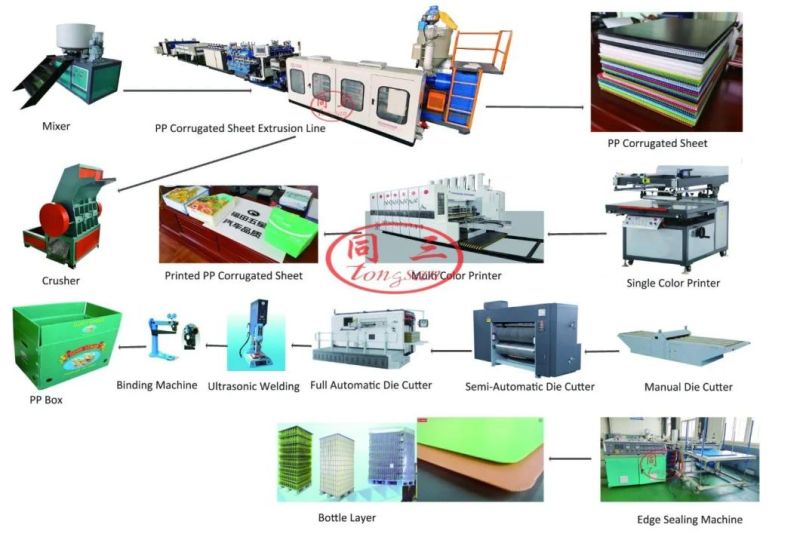

Plastic corrugated hollow sheet box making process

1,Raw material perpare

1,Raw material perpareThe PP filler masterbatch granulating machine for the raw material production.

The waste PP plastic sheet can be cutting into small chip to use directly,or the waste chip after granulating then for extruder.

The PP granules and filler masterbatch and coloe pigment can be mixing for the extruder.

2,PP hollow corrugated sheet production line

Tongsan professional for plastic PP hollow corrugated sheet making machine ,we can provide all series production line for the sheet width range from 1220mm to 2800mm ,the corrugated sheet thickness range from 2-6mm or 7-12mm.

3,Plastic corrugated box making machine

Corona treatment machine for the surface treatment

In order to improve the surface tension of the hollow sheet surface, and thereby improve the printing ink fastness, the hollow corrugated sheet surface will under corona treatment, so that the surface produces micro-concave dense holes, plastic surface roughening, increase the surface activity.

Box sheet printer machine

The printing machine generally consists of a mechanism such as plate loading, ink coating, embossing, and paper feeding (including folding). It works by first making a plate and image to be printed on a printing press, then applying the ink to the place where the text and image are printed on the printing plate by hand or by a printing machine, and then directly or indirectly Printed on paper or other substrates (such as textiles, metal sheets, plastics, leather, wood, glass, and ceramics) to replicate the same print as the plate.

Die cutting machine for the shape of corrugated box,

The working principle of the die-cutting machine is to use a die-cutting knife, a steel knife, a metal mold, a steel wire (or a template carved from a steel plate), and apply a certain pressure through the plate to cut the printed product or the cardboard into a certain shape. If the entire print is pressed into a single graphic product, it is called die cutting; if the steel wire is used to press a mark on the printed product or leave a bent groove, it is called an indentation.

Welding machine or bookbind edge sealing machine

Plastic welding machines are used to weld thermoplastic engineering plastic sheets or products such as polyethylene, polypropylene, polypropylene, and nylon. During operation, the plastic electrode is melted and melted, and the workpiece to be welded is fused and bonded. It is widely used in the welding and maintenance of plastic equipment, plastic floor laying, plastic pipe connection, plastic bottle sealing and so on.

About our company

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23