POM Peek Carbon Fiber Resin Waste Plastic Granules Compounding Extruding Pelletizing Line

SHAOXING SHANGYU REAL SAW CUTTING TOOLS CO., LTD. / 2022-07-04

=== Base Info ===

=== Description ===

32-56

Specification:

1. PSD Series Compounding and Granulating line for Color Master Batch

Introduction of parts of PSD Twin Screw Extruder

PSD Twin Screw Extruder adopts modular design principle, component standardization manufacturing, which can present stable and reliable performance. Thanks to the modular principle, PSD extruders can provide highly customizable solutions according to customers' process and special requirements. Based on different output torque grade, PSD series extruders have basic type and efficiency type.

Process section includes barrels, screw shafts, screw elements, individual temperature heating and cooling unit. Barrels and screw elements are designed in block principle.

Block structure allows the screw elements combine and sequence optimized to realize the process:

Conveying-Plasticization- Compounding & Dispersion- Homogenization- Degassing- Pressure building

Also Block structure allows the barrels adjust freely to the fit the process requirement.

Based on different process position, PSD extruders have different barrels type: feeding barrel, side feeding barrel, close barrel, open on top barrel, vacuum vent barrel, etc. According to the different jobs' requirement, barrels' materials can be nitride steel or bimetallic steel.

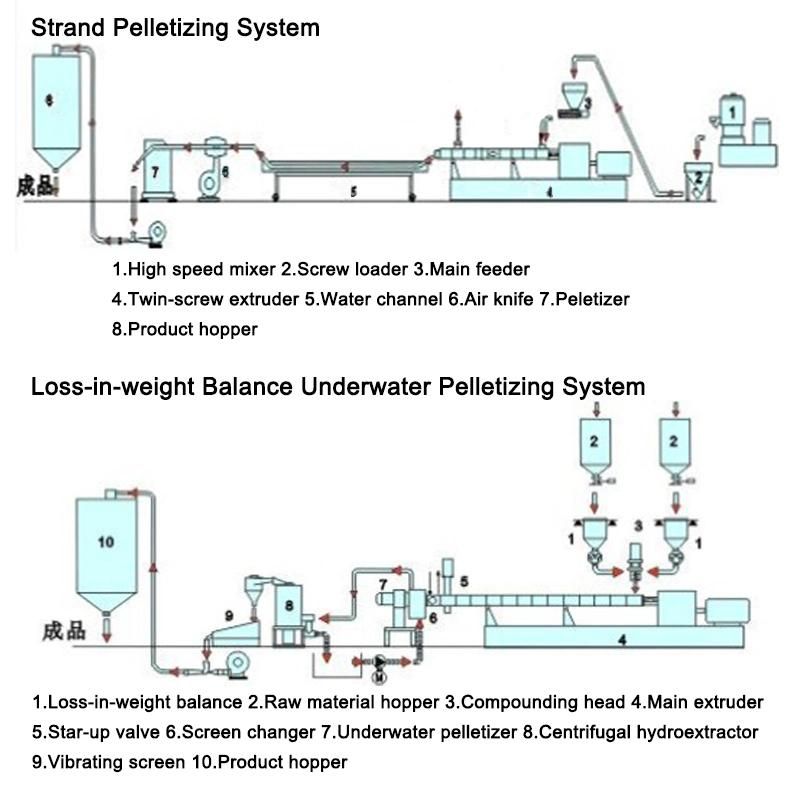

Multiple cutting systems can be combined with PSD Twin Screw Extruder, such as strands pelletizing, hot-face cutting and under-water pelletizing, etc.

Both Instrument control and PLC control are available to apply in the PSD electrical controlling system. All the key electrical parts adopt European brands to guarantee the controlling system with significant and stable performance.

Flow Chart:

Main technical specification

Max.(rpm)

(Kw)

(Nm)

T/A3

(kg/h)

Advantages of color master batch:

1. High concentration of pigment

2. Excellent dispersion, good heat-resistant, high color fastness, stable performance and shows bright color

3. Non-toxic, environmental-friendly

4. Compatible with various material PE/PP/PS/ABS/HIPS/PVC/TPR etc.

5. Wide application: blow moulding, blowing film, injection moulding, extrusion, spin-dyeing, cable sheathing, etc.

6. Range of industrial application: office automation, household appliances, film and packing material, textile, sheet, pipe, medical appliances, toys and so on.

Advantages of the production line

1. It can produce high-quality, high-quantity filler master batch

2. It works with high efficiency

3. It's computerized with high automation

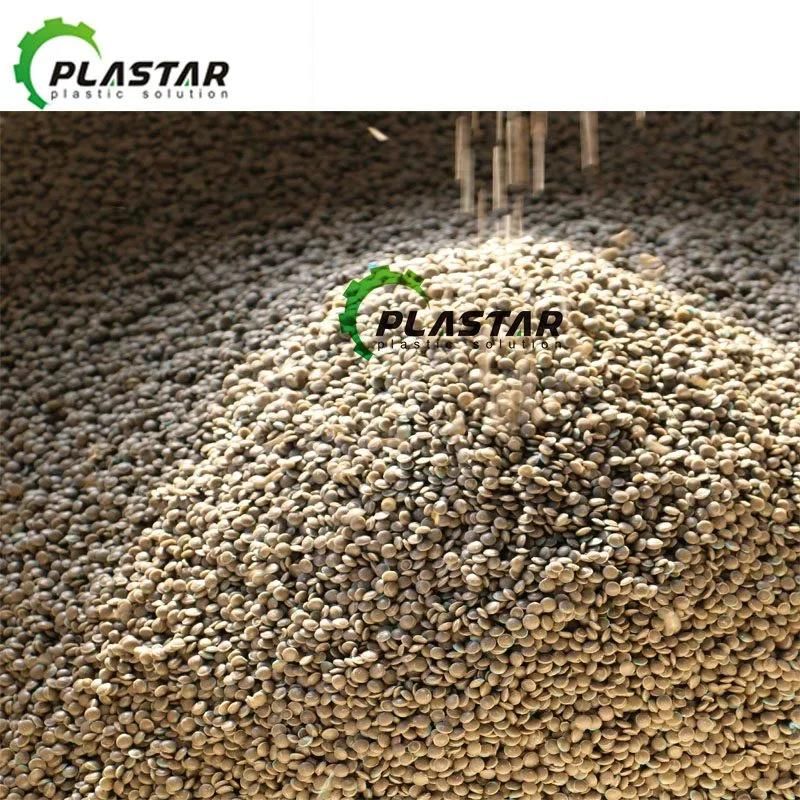

More pelletizing line pictures for reference:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23