100hl Beer Fermenter AISI 304 Conical Cooling Tank

Shenzhen Shiner Packaging Co., Ltd. / 2022-07-05

- Condition:New

- Customized:Customized

- Voltage:According to Local

- Composition:SS304

- Processing Material:Special Agricultural Products

- Process:Ferment

=== Base Info ===

- Model NO.:10000L

- Material:Ss34

- Function:Beer Ferment

- Design:Conical 60 Degree

- Cooling Way:Dimple Cooling Jacket

- Inner Shell:Thickness 3mm

- out Layer:Thickness 2mm

- Temperature Test:PT100 Temperature Sensor

- Inner Surface:Pickled and Passivation

- Insulation:PU Foam

- Welding:Argon Arc TIG 100%

- Transport Package:Steel Frame

- Specification:10000L

- Trademark:Zunhuang

- Origin:China

- Production Capacity:200piece

=== Description ===

Basic Info.

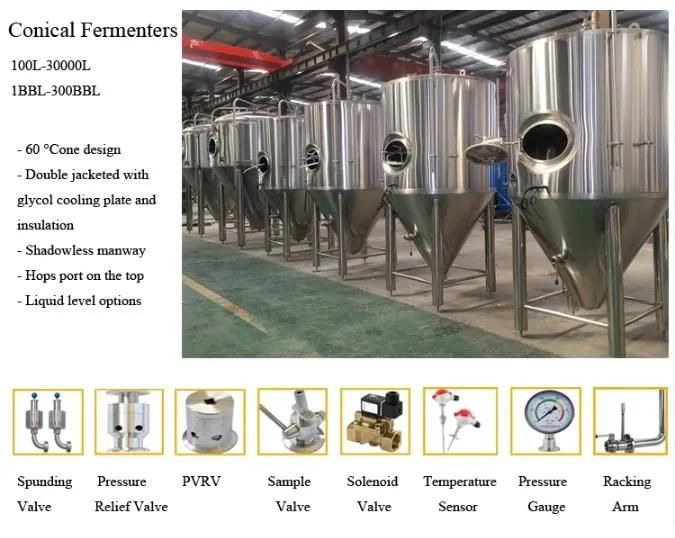

Model NO. 10000L Material Ss34 Function Beer Ferment Design Conical 60 Degree Cooling Way Dimple Cooling Jacket Inner Shell Thickness 3mm out Layer Thickness 2mm Temperature Test PT100 Temperature Sensor Inner Surface Pickled and Passivation Insulation PU Foam Welding Argon Arc TIG 100% Transport Package Steel Frame Specification 10000L Trademark Zunhuang Origin China Production Capacity 200pieceProduct Description

Description:Fermentation Unit

Zunhuang company are generally use 12 days as fermentation to configured fermentation tank,high quality fermentation, fermented good quality beer,the right amount of good commodity market with a bright future.

The fermentation tank adopt cooling jacket and two-stage cooling refrigerant control mode at the cone and cylinder. So such design and cooling method to control the flow of the cooling liquid state in fermentation tank by the size of the two-stage cooling refrigerant flow. It will improve heat transfer efficiency and cooling rate, faster cooling, and reduce cooling costs and high economic efficiency equipment commercial operation.

| Production capacity | 500 | 1000 | 2000 | 5000 | 10000 | 20000 |

| Volume Effective/Total | 500/660 | 1000/1330 | 2000/2660 | 5000/6600 | 10000/ 13300 | 20000/ 26600 |

| Inner shell diameter(mm) | 1400 | 1600 | 2000 | 2800 | 3000 | 3500 |

| Cooling area m2 | 2.2 | 4.4 | 8.7 | 14 | 25 | 48 |

| Working pressure | 0.14 | 0.14 | 0.14 | 0.14 | 0.14 | 0.14 |

| Cooling method | Dimple plate jacket | Dimple plate jacket | Dimple plate jacket | Dimple plate jacket | Dimple plate jacket | Dimple plate jacket |

| Conical angle | 60 | 60 | 60 | 78 | 78 | 78 |

Fermentation Details:

Fermentation Details:Fermentation system:

1. Capacity: 50L-30000L, 1bbl-100bbl, +25% Head space

2. Interior shell thickness 3-6mm, Exterior shell=2mm

3. 100% TIG welding with pure argon gas shield

4. Interior finish: pickled and passivated, external polished, 80mm insulated

5. Test pressure 3 bar, working pressure 1.5 bar

6. Glycol zones (Both on side and concial/bottom)

7. 60°conical bottom for Fermener, Shadow less side man way

8. Racking arm, Sample valve, Pressure relief valve on the top, Dry hopping on the top

9. Mechanical relief valve 3 bar on CIP arm with pressure gauge

10.Adjustable tank leveling pads.

Assorted accessories:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23