Strand Cut Plastic Film Granulator Line

Chenguang Machinery & Electric Equipment Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

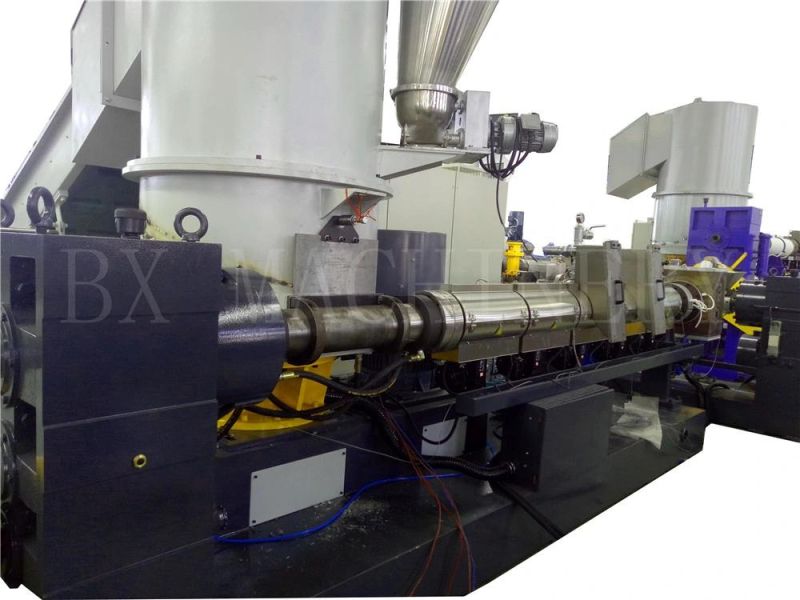

BXC Series Plastic PE PP Film Granulating Line-Compactor type

4.Working steps of the pelletizing system

1. Feeding: as standard design, plastic scraps such as film, filament, raffias conveyed into the compacting room through belt conveyor; to handle rolls' scraps, roll hauling off device is an optional feeding method. Motor drives of conveyor belt and hauling device cooperate with ABB inverter. Feeding speed of conveyor belt or roll hauling off is fully automatic based on how full the compactor's room is. Metal detector can be combined with belt conveyor, and can interlock with control system, to warn and stop the system, in case that metal is found in feeding section.

2.Crushing and compacting: the rotatory blades of compactor will cut up incoming scraps. Frictional heating which caused by high speed rotatory blades will heat and let scraps shrinking just below their agglomerating point. Optimal designed guide structure compacts the material and directs it into extruder screw. Crushes, dries and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder.

3.Plasticization and degassing: A specialized single screw extruder applied to gently melt the pre-compacted material. The plastic scraps will be well melted, plasticized in a 32 to 34D processing section. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with some water content.

4.Melt filtration: a regular single-plate/ piston double-station screen changer or non-stop double-plate/ piston four-station can be installed on head of extruder to present significant filtration performance. The requirements on the filter technology depend heavily on the quality of the input material as well as the planned use of granules.

5..Pelletizing: die-face water ring pelletizing system set as the standard granulating method in ACS system. Self-adjusting pelletizing head for the best granulate quality and long uptime thanks to consistently correct blades pressure. RPM of rotatory blades is automatic based on melt extruding pressure. Advanced dewatering vibration sieve combining with horizontal-type centrifugal dewatering present high performance dried pellets.

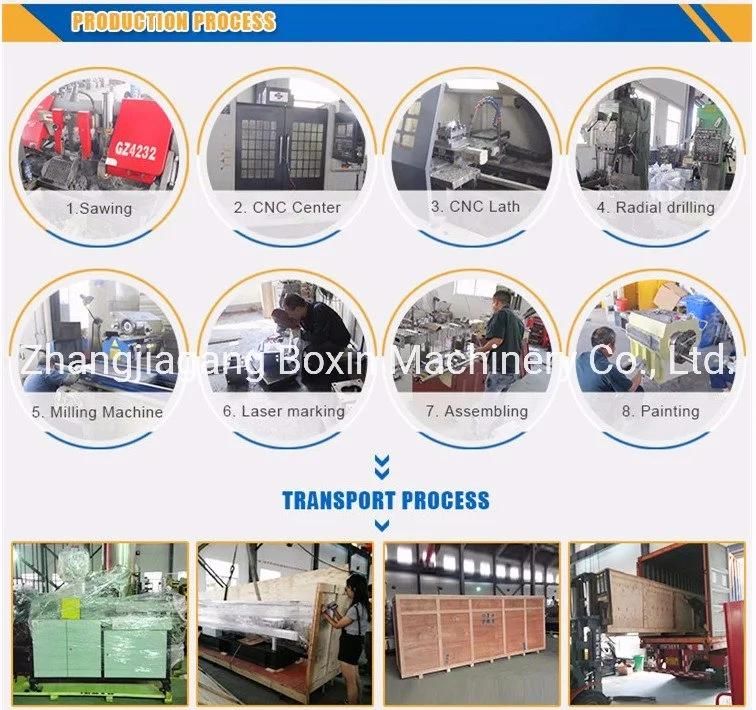

6.Quality Control(plastic machine):

· We have technical, engineer team design the sample machinery before enter into market

· Production QC team ensure the machine manufacturing quality

· We will running every machine after finished before shipment

· Optional choose by client running the machinery by material

7.Service System(plastic machine):

· Pre-sale: We given client the details technician offer, sign the sales contract etc.

· In-sales: We supply the details layout, installation instruction, technician support for the clients;

· After sales: We arrange engineer to install the machinery and training the workers for client;

· We have 24hours team to solve the after sales problem;

· We have free spare parts with the machine;

· We supply long term spare parts for every customer

· We always up date the new technology to every customer

8.Package and Loading

9.FAQ

YOU MIGHT INSTERESTED IN FOLLOWING QUESTIONS

1. Are you manufacturer or trading company?

We are a professional recycling machines manufacturer for more than 15years we supplying full technical support and solutions, timely and professional service, always effort on quality, honest, win-win business for every client.

2. How do you assistant to install the machine on worksite?

We are experienced on turn-key project, engineer and technicians will assistant client on construction, installation, commissioning.

3. How can I get spare parts for replacement in other countries?

Wearing parts like blades, it is necessary to buy with machine, other parts in stock could be delivery out by express if urgent or by sea within 5days.

4. Can I use mark machine with different LOGO and color?

Yes, please confirm details with sales.

5. Can your customers test the machines?

Before buying and after production before leaving factory, we test machine you interested or paid with specified materials, free of charge.

If you have any need ,pls feel free to contact with us.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23