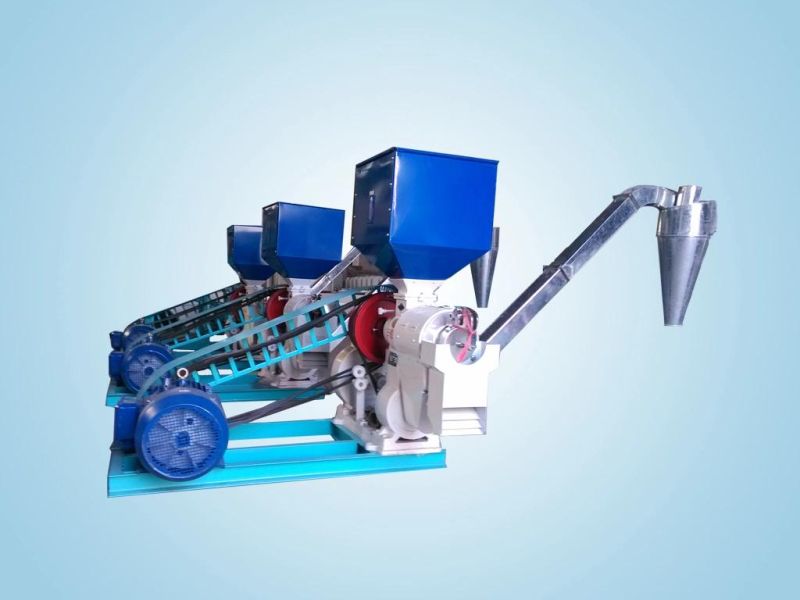

Maize Corn Dehuller Dehulling Machine

Hebei Chenzhou Trading Co., Ltd. / 2022-07-05

- Type:Dehuller

- Application:Beans, Wheat, Corn

- Voltage:380V

- Condition:New

- Customized:Customized

- Transport Package:Export Standard

=== Base Info ===

- Model NO.:SN

- Origin:China

- HS Code:84378000

- Production Capacity:500-6000kg,H

=== Description ===

Basic Info.

Model NO. SN Origin China HS Code 84378000 Production Capacity 500-6000kg/HProduct Description

Dehuller with polisher /corn sheller / corn dehulling machineThis machine is mainly use to peeling the skin of grain such as maize, wheat, mung bean, buckwheat and barley, millet, sorghum, etc. this machine can peel the skin of above. There is screen and grinding wheel in the working cabinet, peeling process is going on through the space between screen and grinding wheel.

As a manufacturer of grain processing machinery, Chengli's dehuller with polisher SN is used for maize dehulling and degerming in the production of maize flour for the grain processing industriy. It is designed to increase maize flour efficiency and flour yield through gentle dehulling and polishing of maize seeds. With two tuyeres, the machine can inhale and blow the light peels and fibers at the same time. It is also capable of processing a wide variety of other seeds.

It is better to wet the corn by little water before peeling and degerming by this machine. This machine can be used separately or with other machines like our Dehuller MNS to peel and degerminate corn to get very low fat dehulled corn in maize milling factories.

Features:

1. Suction system equipped to collect the husks and germs.

2. Fat content rate: below 1%

3. Reliability via sturdy construction.

4. High throughput with little space required.

5. Bran can be collected by air blower to perfect the surroundings.

6. Large output, no broken kernel

Advantages:

- Innovative design, advanced structure, nice exterior;

- Reasonable structure, reliable performance;

- Great sanitation thanks to bran powder collector;

- Change belts without removing spindle, easy operation, widely used;

- High throughput capacities, high quality, smooth kernels;

- Excellent design provides Flexibility with regard to existing spatial conditions.

FUNCTIONAL DESCRIPTION

This machine is new specialized equipment applied for corn hulling, de-germinating, polishing and the removal of tip cap. Raw grains are hulled, de-germinated and polished under the intensive processing of rotating cylinder and screen after the raw materials are delivered into the hulling chamber. The end products achieve the required accuracy after kernel and bran are separated with the help of wind.

The machine is not only can be used alone, but also compatible with complete sets like Grain/seed Cleaner, it can be integrated according to the specific needs in an existing range of machinery. It is an ideal equipment for small and medium size grain processing plants.

| Model | Capacity (t/h) | Power (kw) | Weight (kg) | Dimension (mm) | Rotor speed(R/MIN) | Fan speed(R/MIN) |

| SN115 | 0.6 | 11-15 | 210 | 1550*490*900 | 940-1000 | 4200-4400 |

| SN150 | 1.5-2 | 18.5-22 | 320 | 1650*510*1060 | 940-1000 | 3000-3050 |

| SN200 | 2-2.5 | 22-30 | 980 | 1700*510*1060 | 940-1000 | 3000-3100 |

| SN300 | 3-6 | 37-45 | 1100 | 1750*600*1060 | 940-1000 | 2900 |

The machine consists of iron bar, propellers, wicker basket, screen pieces and others, using the wind pressure principle to achieve the effect of peeling, degerming.

A. sieve plates B. batten for fixing the sieve plate

C. spiral propeller D. Iron roller E. Frame

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23