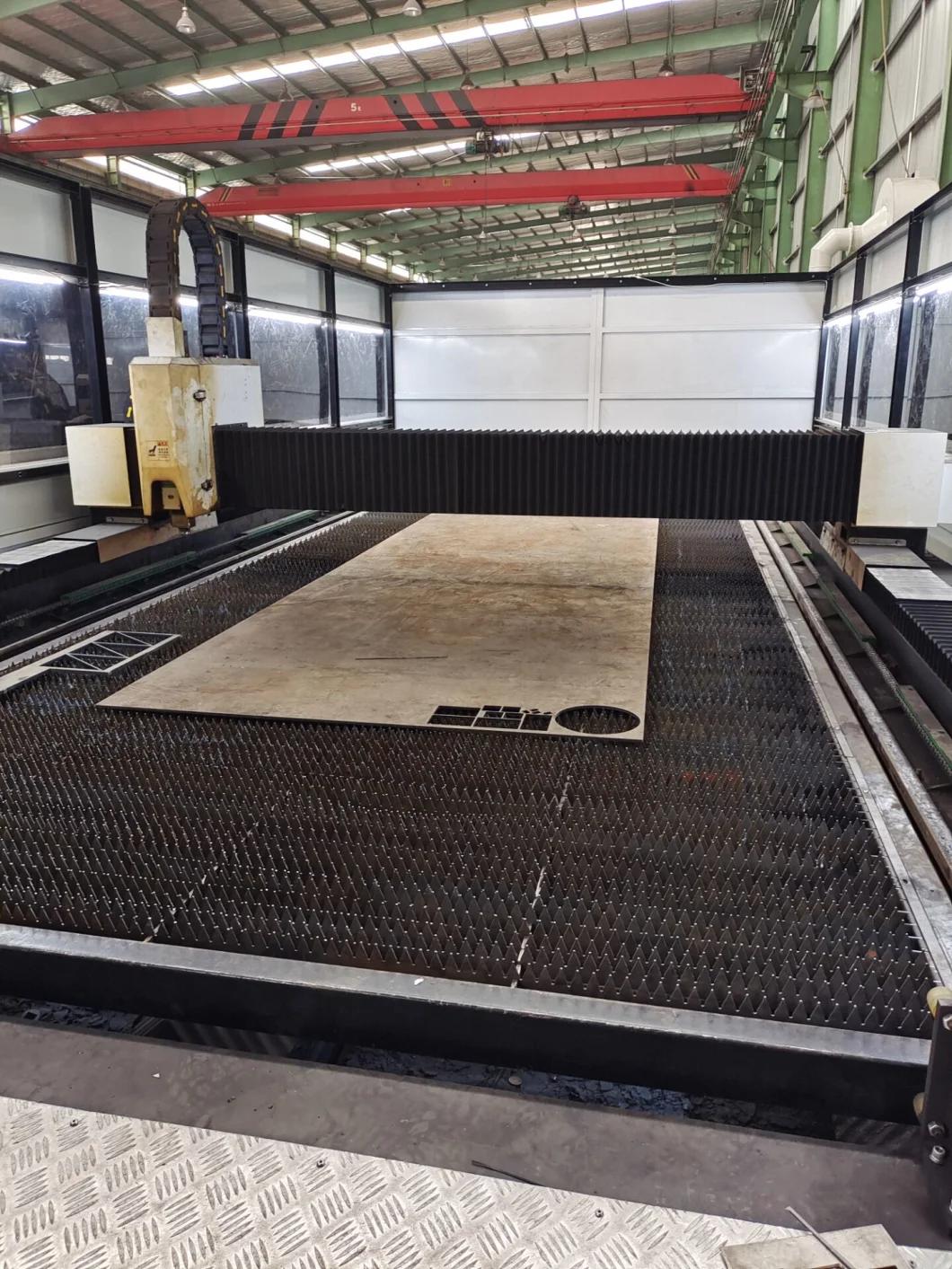

H6020 Laser Cutter Fiber Laser Machine Fiber Laser Cutting Machine

Yiwu Hengcool Crafts Co., Ltd / 2022-06-23

- Warranty:1 Year

- Application:Environmental Equipment, Petroleum Machinery Manufacturing

- Cooling System:Air Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

- Structure Type:Desktop

=== Base Info ===

- Model NO.:H6020MINI

- Laser Classification:Semiconductor Laser

- Laser Technology:Laser Control Fault Cutting

=== Description ===

Technical Specification

Product Name

Laser Cutting Machine

Model

HS6025H

Control System

CypCut

Max Acceleration

1.5G

Repeated Location Accuracy

±0.02mm

Cutting Mode

Laser Cutting

Laser Power

1000W.2000W.3000W

Max Cutting Speed

120m/min

Working Area

Main Features:

1. The machine adopts gantry type single-side double-drive structure, imported high-precision reducer, gear rack and linear guide, smooth transmission, fast acceleration, Bit precision.

2. Both the bed and the moving beam adopt the whole welded structure. After annealing, rough machining and vibration aging, the welding process can be completely eliminated. Processing of stress, rigidity, high precision, can be maintained for a long time without deformation.

3. X, Y axis with high-precision servo motors, bed movement performance greatly improved, acceleration up to 1.5G, to ensure that the whole machine has high speed and high acceleration performance.

4. Using the Windows operating system based CypCut fiber laser cutting machine dedicated CNC system, integrated a lot of laser cutting control dedicated functions Module, powerful, simple operation.

5. Switzerland RAYTOOLS Laser Head is capable of automatic height adjustment to maintain constant focal length and stable cutting quality.

6. Germany imported high-precision electronic proportional valve, precise control of cutting auxiliary gas pressure, in order to achieve the best cutting results.

Laser QMCLaser Source Test

Laser Head Test

Square Track Detection

Rack Detection

Motor / Reducer Testing

The width, repetition frequency and peak power of the laser pulse are detected by using the photoelectric detectors and oscilloscope.

Stability test and aging test for laser head.

Testing the flatness and straightness of the track to ensure that the machine runs smoothly.

The precision and consistency between gear and rack are mainly tested

We will adjust the suitability of the machine through continuous empty experiments.

Process Control

The assembly process of the machine will also affect the customer's feeling when using the machine, Therefore, in the process of machine assembly, Heavth CNC from the most basic machine bed to the final assembly of the whole machine is strictly followed by the quality management standard.

Machine Bed Welding

Gantry Milling

Guide Rack Mounting

Other Hardware Parts Installation

The bed frame is welding by 10mm thick and high strength square.

Heavth CNC has its own gantry milling.

The straightness of guide rack is guaranteed by using laser collimator

we install the motor reducer strictly according to standard production process and standard

Pre-delivery Inspection

The machine will accept a number of quality testing, respectively, from the performance, stability, fit, practical and other aspects of consideration, for non-compliance with the standard part of the arrangements for debugging and maintenance, To ensure that the final factory, the machine is in the best condition.

Inspection Report

The Whole Machine Is Fitted With a Load-Free Test

Material Shearing Test

Machine packing

Every component of the machine, every performance, every parameter is carefully tested.

Ensure the cutting accuracy through laser interferometer checking and 24 hours testing, And make sure the machine will be in the best condition.

Before delivery, different metal materials will be cut, observe the cutting effect, and then adjustment according to the need

The laser equipment requires multiple protective measures during the packing process to ensure that each component is not affected by the collision

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23