Fruit Tomato Paste /Tomato Sauce Production Line

Hangzhou Yale Industrial Co., Ltd. / 2022-07-04

- After-sales Service:1 Year Free Service and Life Time Service

- Warranty:1 Year

- Type:Fruit Processing Plant

- Voltage:380V

- Power:150kw

- Customized:Customized

=== Base Info ===

- Model NO.:CXP-TMT

- Automation:90% Automatic

- Transport Package:Standard Ocean Packing

- Specification:10-1500 Tons Per Day

- Trademark:Chase

- Origin:Shanghai

- HS Code:8422301090

- Production Capacity:1 Set Per 3 Months

=== Description ===

Basic Info.

Model NO. CXP-TMT Automation 90% Automatic Transport Package Standard Ocean Packing Specification 10-1500 Tons Per Day Trademark Chase Origin Shanghai HS Code 8422301090 Production Capacity 1 Set Per 3 MonthsProduct Description

Fruit Tomato Juice Production LineAutomatic Tomato Paste Processing Complete Line is the star product of Shanghai Chase Machinery, Serving worldwide tomato processing factory better and improving food processing technology by manufacturing a wide range of tomato processing line in Kunshan.

We are making available fully domestic made machinery and lines designed according the most modern technology. Complete production line for tomato processing, to obtain tomato paste, tomato sauce, tomato ketchup and drinkable tomato juice. We design, manufacture and supply complete Automatic Tomato Paste Processing Complete Line including:

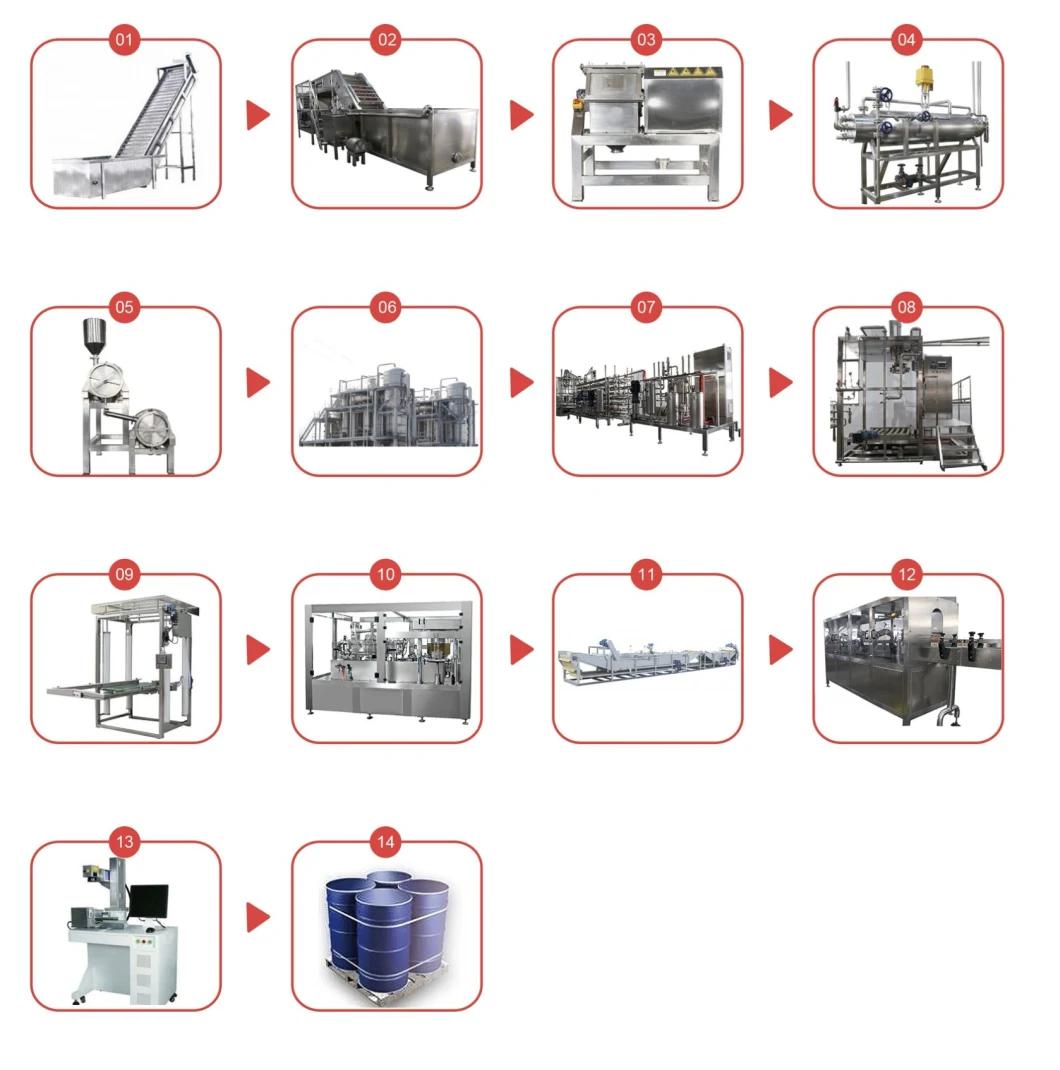

Production Process

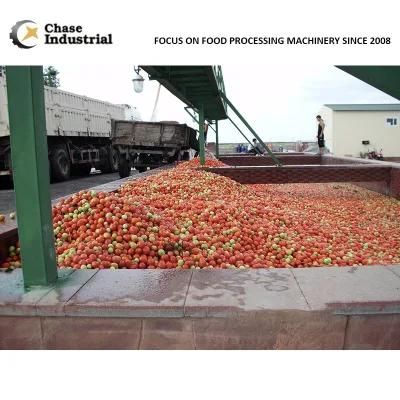

Receiving and Elevating

1. It is advisable to install cement pools in the plant, which provides the processing line with a constant flow of raw material.2. Fresh and ripe tomatoes cannot be stored for over 24 hours at temperature of over 30°c.

3. Chain and plate elevators are normally used for tomatoes elevating, which do little harm to tomatoes. The elevators are

equipped with sprayers, letting the tomatoes be re-washed during the processing of elevating.

4. Motors are equipped with stainless steel protective shield, which keep the motors from rain and snow in outdoor.

Washing and Sorting

1. Bubble washing machine/floating washing machine washes the tomatoes by floating water, which comes from bubble generator quipped at the bottom of the machine. There is no damage brought by bubble washing while the tomatoes are thorough washed.2. Waste and sand sink to the bottom and are discharged by our special design.

3. Rolling bar design & speed adjustable.

4. The machine is equipped with waste conveying system, sending the waste directly to tank.

Chopping and Preheating

1. Supper-high intensity

2. Crossed blades design (rather than harmer slice design, which does harm to materials) litter heat generating during chopping work helps protect vitamins in tomatoes.

3. This process helps pectin inside tomatoes, which gives natural in consistency to the tomato paste.

4. Ii-feed at normal temperature and outlet at 60-90°c. Temperature adjustable.

Refining and Evaporating

1. Rotated speed can go as 1470r/min, which generates large centrifugal force and helps increase the juice yield.

2. Every blade goes through dynamic balance test, with the feature of lower noise and smoother operation.

3. Forced circulation evaporator: Continuous concentration under vacuum and low temperature.

Sterilizing and Aseptic Filling

1. Tube-in-tube sterilizer, which contains heating, sterilizing and cooking section is mainly compose of tube in tube heating-exchanger and feeding pump.

2. Four layers. Auto backtrack of no enough sterilized.

3. Mainly composed of aseptic filling head (single/double), operation system, computer controlling system, weight measurer, operation, platform, and etc.

4. Package forms can be various kinds as customers request

Company Profile

Shanghai Chase Industrial Co., Ltd.

Shanghai Chase Industrial Co., Ltd is founded in 2008, focus on food processing machinery.

We own more than 60 employees with rich industrial experience and advanced mechanical equipment, numbers of CE certifications and invention patents. We have complete service guarantee in equipment manufacturing and after-sale service of fruit and vegetable processing production machine, Diary processing lines, UHT pasteurizing lines and aseptic filling lines.

Chase Production Workshop

Our workshop covers an area of 8000 square meters, with full production space and equipment which meet the requirements of production flows. We have experienced mechanical engineers, electrical engineers and technicians. We design and produce all the important equipment and write PLC control programs by our own staff to ensure perfect after-sales maintenance. All the equipment is strictly inspected and tested in factory before delivery, to ensure smooth operation in customer's site.

Certifications

Transport and Installation

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23