Tomato Sauce, Jam, Mayonnaise, Automatic Filling Production Line

Qingdao Enka Industrial Co., Ltd. / 2022-07-05

- Power Source:Electric

- Certification:CE, ISO9001

- Automatic Grade:Automatic

- Application:Milk, Yogurt, Milk Powder, Cheese, Tomato Sauce, Jam, Mayonnaise

- Customized:Customized

- Transport Package:Wooden Case

=== Base Info ===

- Model NO.:JXP

- Specification:material: stainless steel

- Trademark:Reyes

- Origin:China

- Production Capacity:500sets,Year

=== Description ===

Basic Info.

Model NO. JXP Specification material: stainless steel Trademark Reyes Origin China Production Capacity 500sets/YearProduct Description

Technical parameters:

Object to apply: all kinds of plastic bottle or glass bottle.

Filling volume:50-5000ml

Production speed:600-5600B/H

Length of production line:10m-15m

Power:380V 50Hz 25KW

Air supply: 0.6-0.8Mpa

The above parameter is just for your ref, specific parameter depend on the different actual condition

Production Line introduction:

This production line is designed for production of Tomato sauce, jam, mayonnaise, automatic filling production line, the above producing equipments are necessary for automated production. reduce labor cost, improve the degree of automation and improve product cleanliness greatly.

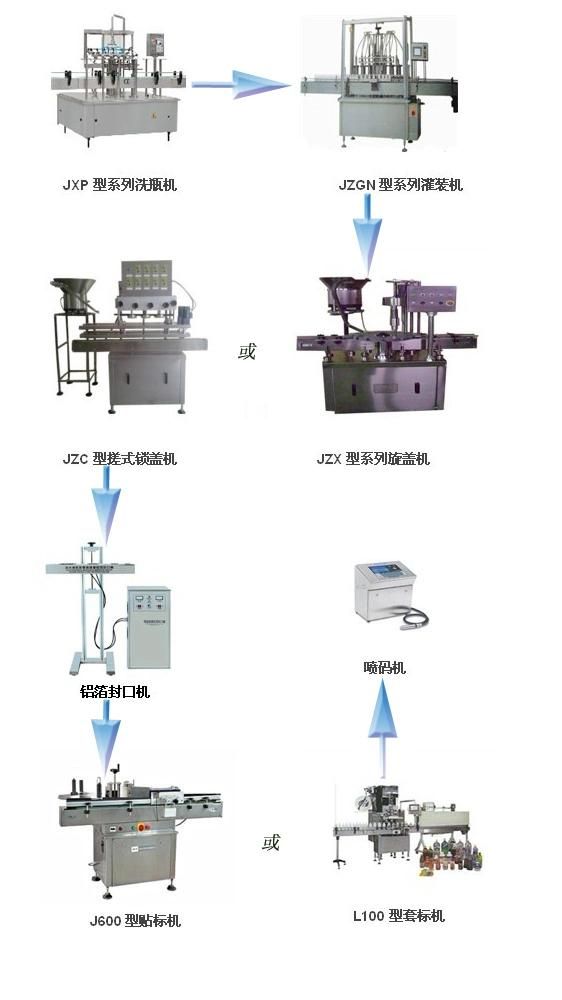

this production line including the equipments: washing machine, filling machine, capping machine, aluminum foil sealing machine, sleeve labeling machine or labeling machine, inkjet printer.

Production line process as following:

1.put the bottles on the convey belt of bottle washing machine by manual worker.

2.washing bottles cleanly by the automatic washing machine.

3.transfer bottles to the filling machine by the auto transfer belt.

4.bottle filling by the filling machine

5.transfer the bottle to the capping machine by auto convey belt.

6.lifteing and feeding the caps to the capping machine by the cap lifting device.

7.automatic capping by capping machine

8.transfer the bottle to the aluminum foil sealing machine for sealing.

9.transfer the bottle to the Shrinking & Sleeving Labeling Machine or labeling machine.

10.automatic shringking and sleeving or labeling by the Shrinking & Sleeving or Labeling Machine.

11.transfer the bottle to the Inkjet printer.

12.print the necessary info on to the products by printer.

Main Character :High degree of automation

Simple and convenient operation

Have Multi-purpose

Adopt import electrical components

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23