Twin Conical Screw PVC/UPVC Profile Extrusion Production Line

Ningbo Conwhole Hardware Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJSZ-65/132 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Length(M) 18 Width(M) 2 Height(M) 3.5 Inverter ABB Electric Parts Siemens Weight 8 Tons Transport Package Wooden Packing Specification Customized Trademark Trusty Origin Qingdao HS Code 84772090 Production Capacity 30 Set/MonthProduct Description

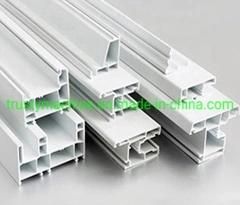

PVC/UPVC window and door profile extrusion line

PVC/UPVC ceiling panel making machine

PVC/WPC wall panel extrusion machinery

1.Company ProfileQingdao Trusty Plastic Machinery Company is a professional company specialize in designing and manufacturing plastic extrusion machine. We introduced and absorbed the advanced plastic processing technology, which can provide the technology and machinery one-step service.

Our machines are exported to more than 20 countries which are located in Europe, Middle East, Africa, South America, Southeast Asia, Russia and other places. and we will also provide the thoughtful after sales service.

2.Production IntroductionPVC/UPVC window profile production line is suitable for making push and pull windows, flat windows, fixed windows, and special-shaped windows. PVC/UPVC window profile production line doesn't influence by any acid and alkali drugs erosion, and the waste gas and salt. Imported improved agent and uv absorbent are used to avoid discoloration, aging and embrittlement in the hot sun, rainstorm, dryness and moisture between -30 and 70 degrees.

Windows are designed with rainproof panels and drainage channels, which can completely isolate rain water from the outside, and plastic-steel doors and windows are excellent fire-resistant materials, not spontaneous combustion, non-combustion, is your ideal choice.

SJSZ-65/132 TWIN CONICAL SCREW EXTRUDER

3.Machine List

| Name | Quantity(set) |

| Mixer-300/600 | 1 |

| Feeder | 1 |

| Twin screw extruder | 1 |

| Extruding mould | 1 |

| calibration mould | 1 |

| Calibration table | 1 |

| Haul off | 1 |

| Cutter | 1 |

| Stacker | 1 |

| Crusher | 1 |

| Miller/pulverzier | 1 |

4000MM-6000MM CALIBRATION TABLE

CATERPILLAR HAUL-OFF MACHINE

5.Production Process

Mix the material→Feed→Extrude→Mould→Haul off→Cut→Stack the material

6.After sales service

(1)After the machines are finished, the seller will test all machines before shipment. If the buyer can not come to test the machine, we will test the machines and send the sample to buyer.

(2)After shipment, the seller will send one or two technicians to the buyer' s factory to help the buyer install the machine and train workers for buyer.

(3)We will supply all electricity drawing, machine installation drawing.

(4)When make shipment, we will put some spare electricity parts for free, like the barrel hearers, thermcouples, breakers, relays, and other items which is easier broken.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23