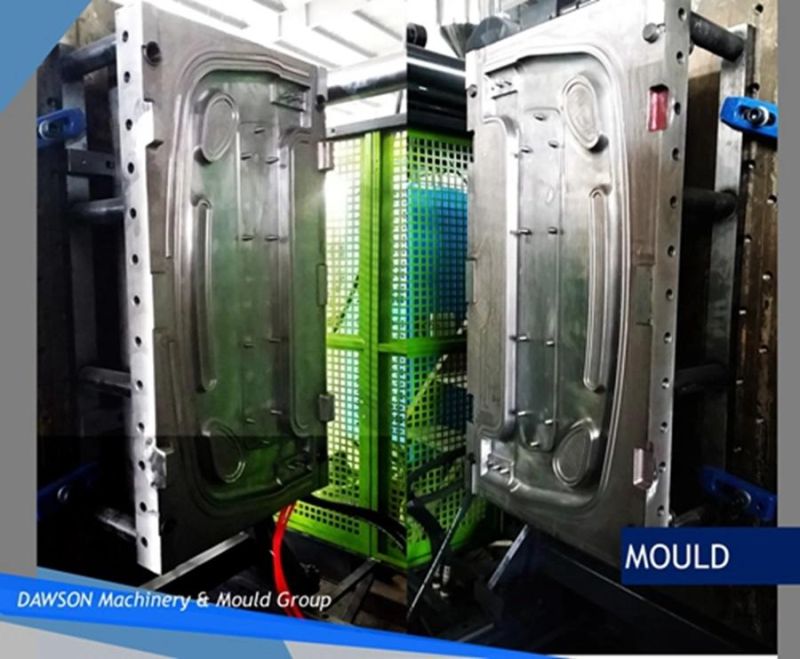

Blowing Moulding Machine for Edical Bed Board

Zhejiang Tengmei Industry and Trade Co., Ltd / 2022-07-04

=== Base Info ===

=== Description ===

MOOG

Machine water consumption

Mold water consumption

| Type of Blow Molding Machine |

Extrusion blow molding In Extrusion Blow Molding (EBM), plastic is melted and extruded into a hollow tube (a parison). This parison is then captured by closing it into a cooled metal mold. Air is then blown into the parison, inflating it into the shape of the hollow bottle, container or part. After the plastic has cooled sufficiently, the mold is opened and the part is ejected. EBM processes may be either continuous (constant extrusion of the parison) or intermittent. Types of EBM equipment may be categorized as follows: 1. Continuous Extrusion Equipment

Basic polymers, such as PP, HDPE, PVC and PET are increasingly being co-extruded with high barrier resins, such as EVOH or Nylon, to provide permeation resistance to water, oxygen, CO2 or other substances. In dairy applications, it is possible to extrude a black light-blocking layer in the center layer of containers, with opaque white resin used in the inner and outer layers. Compared to injection molding, blow molding is a low pressure process, with typical blow air pressures of 25 to 150 psi. This low pressure process allows the production of economical low-force clamping stations, while parts can still be produced with surface finishes ranging from high gloss to textured. The resulting low stresses in the molded parts also help make the containers resistant to strain and environmental stress cracking. Accumulator Head Machinery is used for the extrusion blow molding of large industrial hollow parts. Examples of parts produced on this machinery include drums, trash cans, automotive panels, playground equipment, and large containers, such as Jerry Cans, for liquid storage. Most parts produced on accumulator head machinery are single layer; however, specialized machinery is capable of producing parts with up to seven unique layers of plastic - these machines are used primarily to manufacture automotive gasoline tanks with barrier layers. |

| Plastic machines we provide .... |

Extrusion Blow Molding Machine Injection Blow Molding Machine PET Blow Molding Machine Injeciton Molding Machine Injection Stretch Blow Molding Machine |

| Applictions .... |

Chemicals : Pesticide bottles and industrial buckets, chemical buckets and other hollow blow-molded buckets. Cosmetics&Pharmaceuticals : Vaccine bottles, medicine bottles, medical bed boards, cosmetic boxes, jars and vaseline bottles and other plastic machinery products used in cosmetic and medical fields. House hold : Plastic empty blow-molded bottles, plastic containers, such as shower gel bottles, shampoo bottles, body lotion bottles, laundry detergent bottles, cleaning supplies bottles, hand sanitizer bottle, disinfectant bottle, alcohol disinfectant bottle etc. that are often used in daily life. Indoor & outdoor : Plastic products are widely used, such as plastic hollow flower pots, plastic watering cans, plastic pet houses, plastic cold storage boxes, plastic children's toys, plastic-bus chairs, plastic tables and chairs, plastic trash cans, plastic traffic cones, plastic life buoys, plastic floats , Plastic buoys, plastic mannequins, etc., plastic machinery products can be seen everywhere. Food & Beverage : The common applications of plastic products in the food and beverage industry are ketchup bottles, soy sauce bottles, honey bottles, mustard sauce bottles, milk bottles, yogurt bottles, juice bottles, alcohol bottle etc. Baby bottles are also common in plastic machinery in the beverage and food industry Applications. Lubrication : The most common applications for hollow extrusion blow molding machines are lubricating oil barrels, 1L 2L lubricating oil bottles, 5L 10L cans, 10L 20L 25L to 30L lubricating oil Jerry can, and even 60L ~ 250L large barrels. Automotive : The application of plastic products also accounts for a large part of automobile parts, such as plastic parts in automobile engines, plastic automobile safety stalks, plastic door handles, plastic car lamp housings, etc. |

#blow molding machine #Extrusion Blow Molding #Injection blow molding machine #PET blow molding machine # injection molding machine # blowing mould # plastic bottle making machine #plastic bottle mould #bottle machine #plastic machinery #blow molding mould #moulding machine # moulding mould #China blow molding machine #blow molding machine made in China

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23