Edible Oil Press Machine, Soybean Canola Sunflower Oil Refinery Machine, China Factory OEM

Guangzhou Qiandelu Technology Co., Ltd. / 2022-07-04

- Application:All

- Type:Oilseed Press and Oil Refining

- After-sales Service:Spare Parts, Field Service

- Voltage:380V

- Press Materials:Rapeseed

- Condition:New

=== Base Info ===

- More Information:Design by Customer Requirement

- Worker Quantity:3-5persons Per Shift with Auto-Control System

- Warranty Period:One Year

- Installation Time:2 Months

- Delivery Time:3 Months

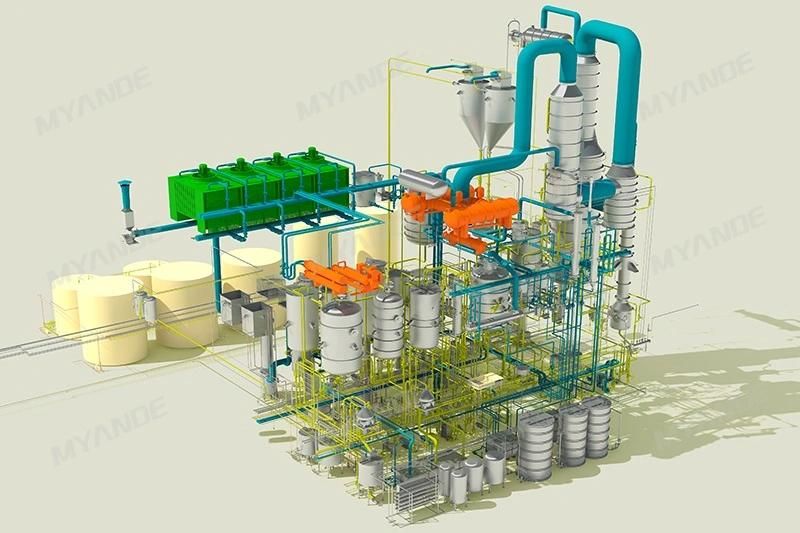

- Design:3D

- Capacity:50-1200t,D

- Brand:Myande

- Customized:Customized

- Model NO.:myande

- Transport Package:Container

- Specification:CE ISO SGS BV

- Trademark:Myande

- Origin:Yangzhou

- Production Capacity:200units,a

=== Description ===

Basic Info.

Model NO. myande Customized Customized Brand Myande Capacity 50-1200t/D Design 3D Delivery Time 3 Months Installation Time 2 Months Warranty Period One Year Worker Quantity 3-5persons Per Shift with Auto-Control System More Information Design by Customer Requirement Transport Package Container Specification CE ISO SGS BV Trademark Myande Origin Yangzhou Production Capacity 200units/aProduct Description

Edible Oil Press Machine, Soybean Canola Sunflower Oil Refinery MachineChina Factory OEM

Engineering Service

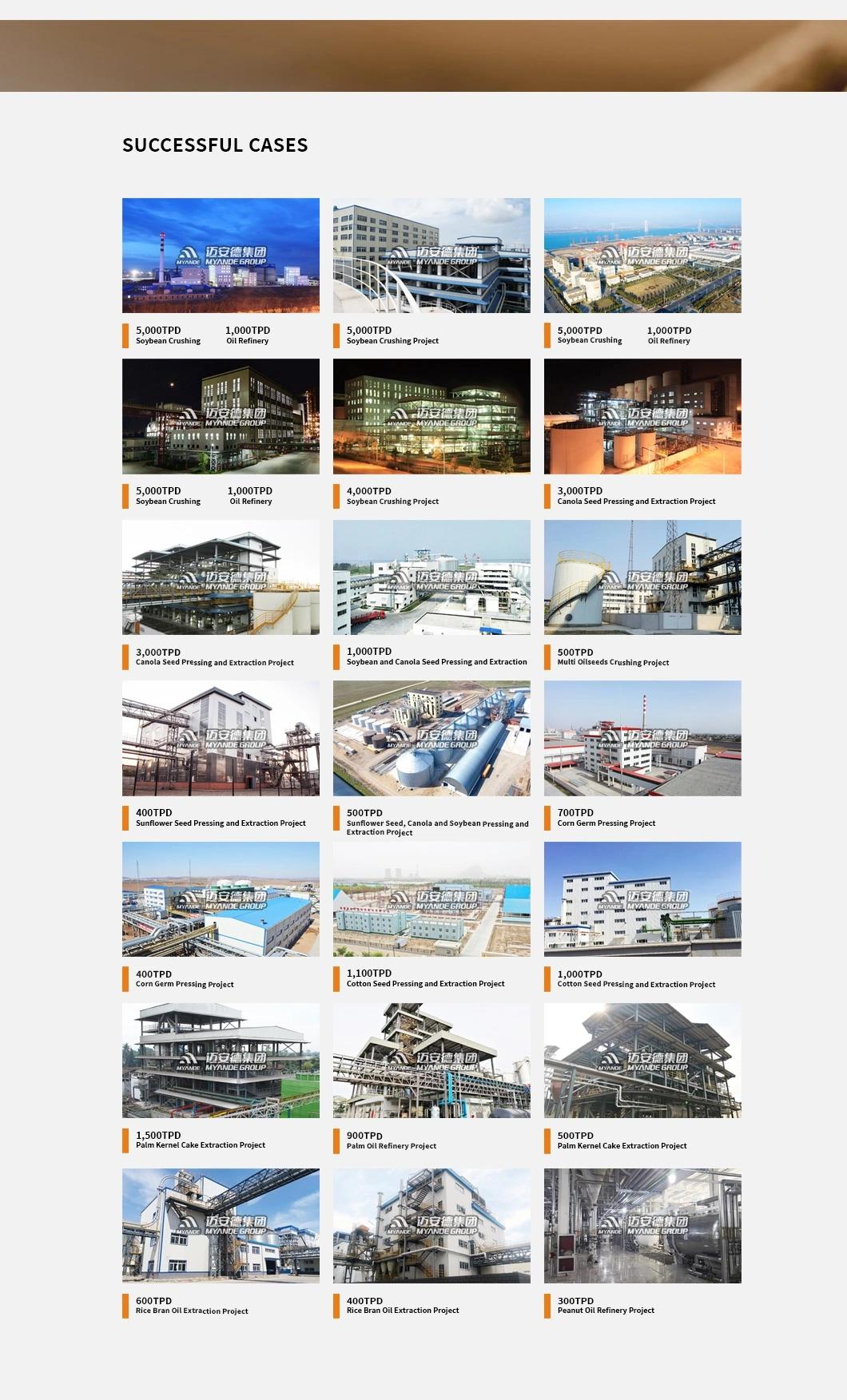

Providing Turn-key Projects for

Soybean Oil Refinery

Canola Seed Oil Refinery

Cotton Seed Oil Refinery

Sunflower Seed Oil Refinery

Peanut Oil Refinery

Rice Bran Oil Refinery

Safflower Seed Oil Refinery

Corn Germ Oil Refinery

Tea Seed Oil Refinery

Other Crude Oil Refinery

Process Description

The objective of refining is to remove objectionable co-constituents in edible oil with the least possible damage to glycerides and minimal loss of desirable constituents. Methods of refining depend on nature and quantity of impurities contained in crude oil, application of RBD oil.

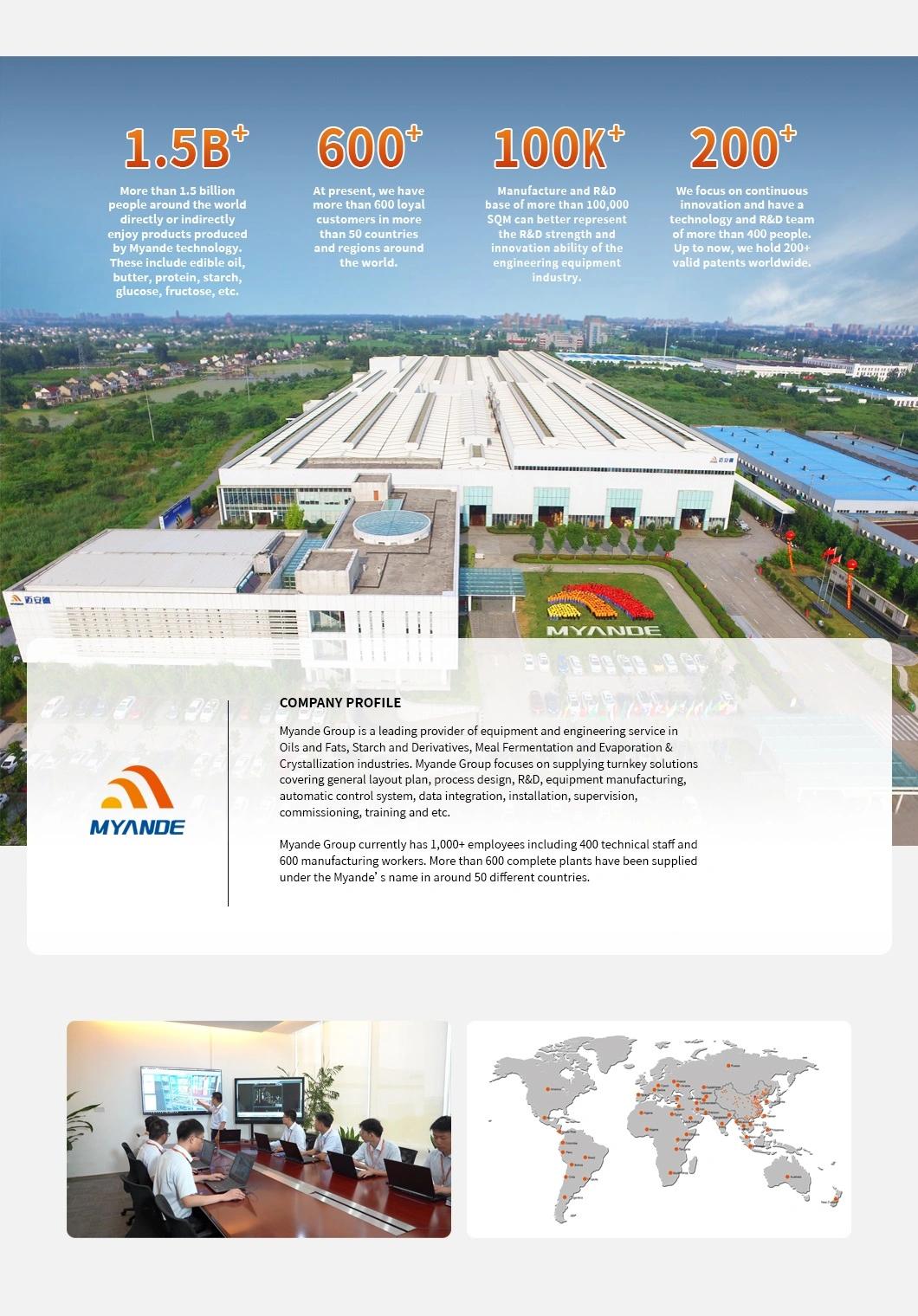

The common refining process includes Degumming, Neutralizing, Bleaching, Deodorizing and sometimes dewaxing (Mainly removing free fatty acid and other minor constituents). The process is suitable for refining soybean oil, rapeseed oil, sunflower oil, palm oil and etc.Myande oil refinery technology is the result of years of research into and innovation of traditional mainstream refinery techniques covering purification, degumming, dewatering, deacidification, bleaching, dewaxing, deodorization and so on. Its most important feature is its high flexibility enabling it to cater to any special requirements of the user for the final products in relation to flavor and physical-chemical properties. With first-class manufacturing facilities, comprehensive quality standards, and fully automatic computer control system, Myande provides high-class technology services for clients with different refinery requirements.

1. Degumming

The purpose of degumming is to remove impurities such as phospholipids, gums, proteins and etc. There are several methods as follows: water degumming, acid degumming, special degumming and etc.

2. Neutralizing

The purpose of neutralizing is to remove free fatty acid in edible oil by using caustic soda while removing impurities such as phospholipid, pigments, metal ions and peroxide under the adsorption of soap stock.

3. Bleaching

Bleaching is the process which removes coloured matters by mixing bleaching earth with edible oil under controlled conditions of temperature. After proper mixing with bleaching earth for a specific residence time, the mixture is finally pumped into leaf filters with stainless steel mesh elements followed by polishing filtration.

4. Deodorizing

Deodorizing is the final stage in edible oil refining in order to remove odoriferous material, free fatty acids and other undesired minor components by steam distillation under conditions of high temperature and vacuum to produce a bland oil with a good shelf life.

5. Dewaxing

Through automatic control system, combined with crystallization curve (time-amount of crystallinity) of different oil, crystals in oil grow and finally can be separated by filtration to obtain dewaxed oil.

Engineering Capacity

We can provide complete crude edible oil refinery equipment with capacity ranging from 50 to 3,000 t/d.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23