WPC Door Boards Production Machine Line

CHINA GTL TOOLS LIMITED / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

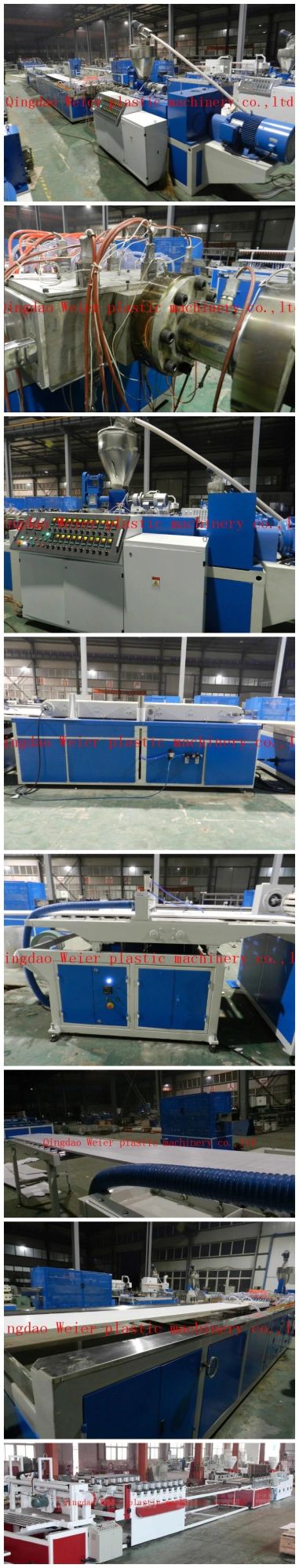

Model NO. 80/156 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Material PVC Add Wood Powder WPC Plastic Machinery Most Professional Supplier Width 1220mm, 1580mm;or Follow Requests by Client Thickness 3-25mm High Output 250-450kg/Hr WPC Door Boards Production Machine Line WPC Door Boards Production Machine Line WPC Door Machine High Output WPC Door Frame Making Machine WPC Door Profile Machine WPC Door Production Line 800mm Width Transport Package Simple Packing Specification CE, BV, SGS ISO2008 Trademark WEIER Origin Qingdao China HS Code 8477209000 Production Capacity 10 Sets/MonthProduct Description

WPC PVC PE Door boards production machine line:

Production line introduction

This line is newly developed on basis on combining domestic and abroad technology.

It is used to produce the PVC wood composit foam door board. The surface can be hot stamped

or printed, also the surface can be engraved with different designs.

WEIER series of wide plastic sheet production line mainly used: PVC + wood flour. Production

overall door, construction and other wood-plastic plate Templates before the extrusion.

The line I use the original wood-plastic technology companies and formula. Plates can be based

on different sections, according to the different uses of sheet metal, product design different proportions.

Selection of different specifications for the wood-plastic twin-screw extruder, and wood-plastic for

single screw extruder, and the corresponding vacuum stereotypes targeting Taiwan, traction machines,

horizontal cutting machine, expected over platforms such as auxiliary equipment.

Replacement of a different mold can produce different specifications of the plastic sheet. Traction

for the company I used a unique technology, steady work, good reliability, great traction.

Increase the use of special vacuum stereotypes swirl cooling system, to facilitate cooling stereotypes,

to meet the wide wood-plastic plate to the needs of the production features.

Cutting sheet metal device with the horizontal speed traction to keep pace, design reasonable, stable

operation, can automatically.

Guarantees:

1. Product electrical components to implement quality assurance for six months (from date of shipment)

2. Equipment Quality Assurance warranty period of one year (from date of shipment)

3. Quality guarantee period, should the damage appears artificial parts, the company will be provided

Free of charge to the purchaser Manufacturers

4. Quality guarantee period, the company will provide the most preferential prices paid to the purchaser

Manufacturers

5. "Supply-side free of charge to provide the main electrical appliances, spare parts manual and

Maintenance of books, equipment manuals, and machine maintenance information, provision of

Equipment, Water, electricity, gas and equipment installation plans.

Packaging & Delivery

1.The machine body is covered by waterproof film firstly, and then fixed on exported wooden pallets

with bolts and wires.

2.The electric controlling parts and spare parts are loaded separately in wooden box.

3.The auxiliary equipments are packaged in wooden box as well.

4.All wooden material is fumigation certificated and safe for exporting to all over the world. wooden

packaging is 49.5USD/m3.

Delivery Time

30 working days

Our Service

Pre-sale

We provide presales service in various forms, for example, making investment budget, manufacturing

planning, etc. so that customers make a reasonable plan with less cost.

Investment budgeting---We provide services of product profit analysis, recommendation of machine and

auxiliary equipment and relevant budgeting, human resources allocation and budgeting.

Plant Planning---We provide the mounting dimension of the equipment base, design of equipment layout,

workshop ventilation, water transmission etc.

On-sale

Detailed design of workshop lay-out

Technological information of provided products

Schedule about design, manufacture and installation

Working & Producing process

Training courses for the technician team so that the installation is safe and standard

After-sale

For customers buying our products, we provide them training so that they can use and maintain the

machine independently.

We will offer to customers technical support in time. If needed, we will offer on-line guidance

and assistance.

We can provide free technical guidance if customers need new equipment, add or rebuild equipment.

We will prioritize the product upgrading of previous customers.

Our Company

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23