Plastic Bottle Mould Blowing Equipment Beverage Bottles Production Line

Yuyao Yipin Tool Co. Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Overview

Product Description

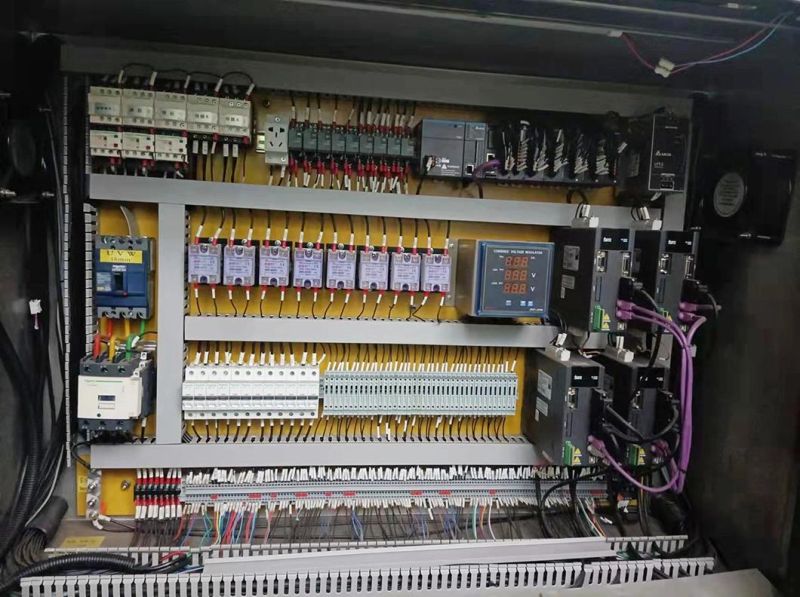

LD4200-2Z is a new type of automatic PET bottle blowing machine. The machine uses the touch screen as the operation interface and PLC programming controller for action arrangement, which can control and feed back the whole production process. It has the function of remote debugging. It is an upgraded product of pet pet bottle making machinery.

LD4200-2Z has 2 separate mould cavities, 1 cavity on each side, it can blow 2 different shape of bottle at the same time.Productivity can reach 4200-5200 bottles per hour (take 14 grams of 500ml bottle for example), and it can blow 2L max bottle size.

Only high-pressure gas is used, no need to equip with low-pressure supporting system. All low-pressure gas, including pre blowing, adopts recycled high-pressure gas.

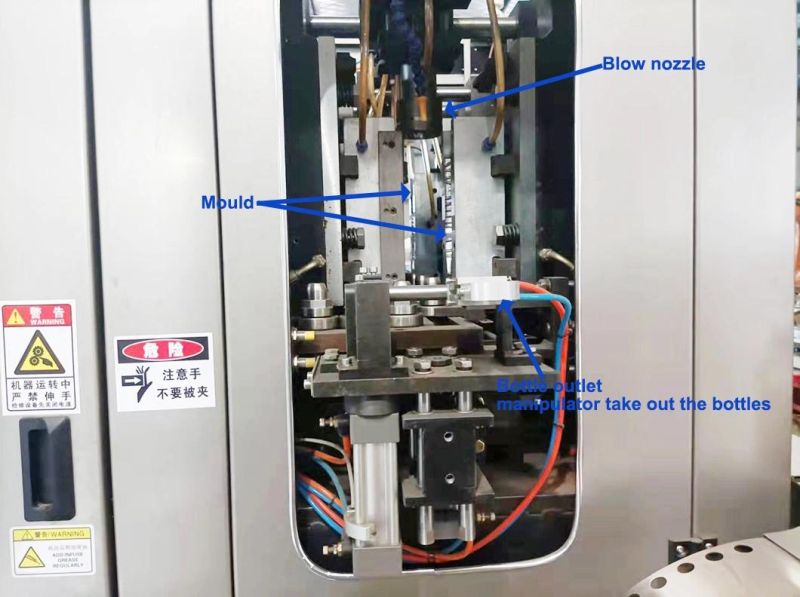

The two sides are independent circulation system, which can be adjusted separately to improve the yield. At the same time, two different bottle shapes can be blown at the same time. Molds with high accuracy can achieve the best effect.

Product Parameters

Detailed Photos

The biggest feature of this equipment is energy saving, which can save 20 to 30 kwh per hour under the same output. Energy saving is mainly reflected in the following aspects

1. The bottle discharging and bottle preform heating device adopts the setting of public baking bottle preform. The bottle discharging direction is on both sides of the machine. There are separate tracks on both sides to run forward with the bottle preform. The heating device is in the middle of two slide rails. It adopts a new design. One heating device is shared by two slide rails to maximize the use of energy.

2.Compact bottle preform arrangement to achieve maximium utilization of the heating energy.

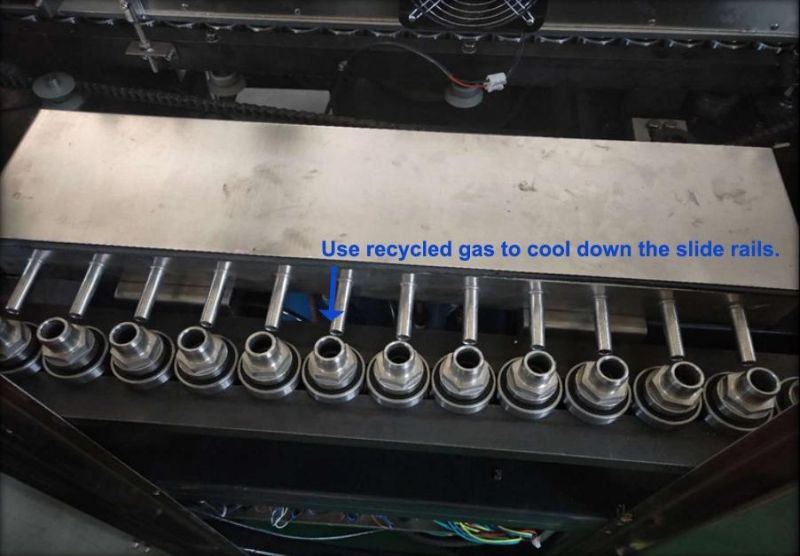

3.Two groups of light boxes using separate box temperature control maximum use of the light and heat, and use recycled gas to coll down the slide rails.It save the cost of low pressure device and save the energy consumption of the low pressure device as well.

Mor product deatils:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23