China Factory 100W 200W 500W 1000W 1500W Handheld Clean Laser Rust Removal Cleaner Machine Price Fiber Laser Cleaning Machine Price

Yuhuan Green Island Plastic Packaging Factory / 2022-06-23

- After-sales Service:Online After-Sales Service

- Power:1000w

- Control Type:Handheld

- Warranty:1 Year

- Products Name:100W Fiber Laser Clean Rust Paint Remover Machine

- Laser Power:100W

=== Base Info ===

- Model NO.:DPH-500,1000,1500

- Operation Type:Automatic

- Cooling Method:Air Cooling

- Operating Mode:Hand Holding

- Operating Environment Requirement:Temperature: 0-40ºC, Humidity :20%-80%

- Model Size:830mmx560mmx1050mm

- Beam Quality:M2<1.8

- Lifetime:≤10W Hrs

- Frequency:80-1000kHz

- Electricity Demand:AC220V,50Hz

- Certification:CE, SGS, ISO

- Usage:Rust Paint Remover Machine

- Gross Power:2kw

- Transport Package:Plywood Package

- Specification:830mmX560mmX1050mm

- Trademark:Dp

- Origin:Shenzhen China

- HS Code:8422200000

- Production Capacity:300

=== Description ===

Basic Info.

Model NO. DPH-500/1000/1500 Operation Type Automatic Cooling Method Air Cooling Operating Mode Hand Holding Operating Environment Requirement Temperature: 0-40ºC, Humidity :20%-80% Model Size 830mmx560mmx1050mm Beam Quality M2<1.8 Lifetime ≤10W Hrs Frequency 80-1000kHz Electricity Demand AC220V/50Hz Certification CE, SGS, ISO Usage Rust Paint Remover Machine Gross Power 2kw Transport Package Plywood Package Specification 830mmX560mmX1050mm Trademark Dp Origin Shenzhen China HS Code 8422200000 Production Capacity 300Product Description

China Factory 100W 200W 500W 1000W 1500W Handheld Clean Laser Rust Removal Cleaner Machine Price Fiber Laser Cleaning Machine PriceOur core advantages (We are looking for distributor )

1) Top 3 laser company in China. Sold 4500 units of laser machines in China market per year, with best price.

2) Usually have 50 units of laser marking machine(Fiber, CO2, UV, Mopa) in stock, lead time 3-5 days.

3) Fiber Laser cutting machine, ( 500 - 12000W laser cutter), usually sell 60 units/month in China.

Technical Parameters:

| Model | DPH-100SCQX-CX-HL | DPH-1500SCQX-CX-HL | DPH-2000SCQX-CX-HL |

| Laser Power(W) | 1000W | 1500W | 2000W |

| Spot Mode | Single-mode/multi-mode | Single-mode/multi-mode | Single-mode/multi-mode |

| Power Adjustment Range(W) | 10-100% | 10-100% | 10-100% |

| Weight of Cleaning Head(KG) | 0.8KG | 0.8KG | 0.8KG |

| Scan Width(MM) | 10-120mm | 10-120mm | 10-120mm |

| Working Distance(MM) | 200400mm | 200400mm | 200400mm |

| Cooling Method | Water cooling | Water cooling | Water cooling |

| Power Supply | 220V-50/60HZ | 380V-50/60HZ | 380V-50/60HZ |

| Maximum Power Consumption(W) | 5000W | 7000W | 9000W |

| Operating Temperature(ºC) | 5-35ºC | 5-35ºC | 5-35ºC |

| Weight(KG) | 200KG | 200KG | 250KG |

| Size(mm) | 830mmX560mmX1050mm | 830mmX560mmX1050mm | 830mmX560mmX1050mm |

| Cleaning Efficiency: Paint/Rust 20um | 45m2/h | 67.5m2/h | 90m2/h |

| Cleaning Efficiency: Oily 20um,(m2/h) | 62m2/h | 90m2/h | 120m2/h |

| Cleaning Efficiency: Titanium alloy oxide film/stainless steel weld, (m2/h) | 28m2/h | 40.5m2/h | 55m2/h |

Performance comparison of handheld laser cleaning machine and other cleaning methods:

| Chemical Cleaning | Mechanical Polishing | Dry ice Cleaning | Ultrasonic Cleaning | Laser Cleaning | |

| Cleaning Method | Chemical cleaning agent | Mechanical/sandpaper, contact type | Dry ice, non-contact | Cleaning agent, contact type | Laser, non-contact |

| Workpiece Damage | Damaged | Damaged | no damage | no damage | no damage |

| Cleaning Efficiency | Low | Low | Middle | Middle | High |

| Cleaning Effect | Generally, uneven | Generally, uneven | Excellent, uneven | Excellent, small clean area | Very good and clean |

| Cleaning Accuracy | Uncontrollable, poor accuracy | Uncontrollable, average precision | Uncontrollable, poor accuracy | Cannot be cleaned within a specified range | Precise and controllable, high precision |

| Safety/Environmental Protection | Serious chemical pollution | polluted environment | No pollution | No pollution | No pollution |

| Manual Operation | The process is complex and requires high requirements for the operator, and protective measures are required | Strong physical strength, need safety protection measures | Simple operation, handheld or automated | Simple operation, but need to manually add consumables | Simple operation, handheld or integrated automation |

| Consumables | Chemical cleaning agent | Sandpaper, grinding wheel, whetstone etc. | Dry ice | Dedicated cleaning fluid | Only need power supply |

| Cost input | Low initial investment, high cost of consumables | High initial investment and high labor cost for consumables | Medium investment for the first time, high cost of consumables | Low initial investment, medium cost of consumables | High initial investment, no consumables, low maintenance cost |

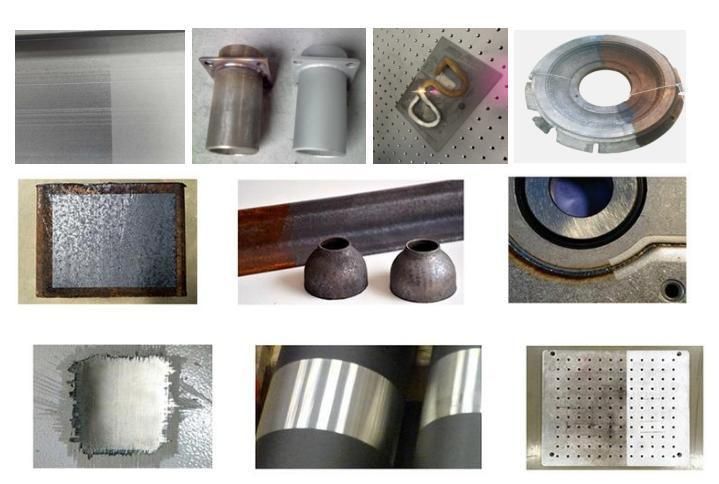

Samples:

Shenzhen Dapeng Laser Technology Co. Ltd.

Shenzhen Dapeng Laser Technology Co., Ltd. was established in 2008, is a research and development, manufacturing, sales and service in one of the laser equipment high-tech enterprises, is committed to laser technology research and development, laser equipment design research and development, production,

technical support, services and consulting

The company's main products include: laser cutting machine, laser welding machine, laser marking machine, industry-specific and automated laser equipment, etc. Products Used in electronics, IC chips, electrical appliances, lighting, jewelery, hardware tools, sanitary ware, instrumentation, automobile and motorcycle accessories, mobile communication parts, mold, precision machinery, medical equipment, IT digital, metal shell, military aviation components , Clothing leather, craft gifts, advertising decoration, model, cookware tableware, kitchenware and other industries

Dapeng laser product quality is stable and reliable, with professional R & D team, the pursuit of excellent quality at the same time, Dapeng laser also provides customers with timely, comfortable pre-sale, sale, after-sales service and excellent cost-effective products.

Dapeng laser through the implementation of "to help customers succeed, create value model, to create industrial laser equipment industry services high-end brand" business philosophy, won the majority of users trust and praise. Customers located throughout the country and overseas, 2016 sales of laser equipment more than 5,000 sets .

The company established a sound production and sales and after-sales service system, in Shenzhen, Wenzhou, Kunshan, Xiamen has a production base. In Dongguan, a large laser cutting machine production base.

And in major domestic industrial cities and regions with offices, the offices have equipment display, process proofing, sales and after-sales service, resident technical service personnel, to provide customers with timely, comfortable pre-sale, sale, after-sales support And services.

Dapeng people know that quality and service is the fundamental survival of the company, innovation is the basis for long-term development of the company to help customers create value, and strive to build the laser equipment industry well-known brands, look around the world, win-win cooperation and create a better future

Notes:

(1) Pre-sale service

1.According to customer requirement, we provide you with the relevant professional technology information (including the specification, machine pictures, working videos, manual) and test samples by our machines.

2.Welcome to visit our company, we will let our engineer do marking or welding on samples. Seeing is believing, and it is

better for future business.

3.We offer a reasonable price for mutual win-win cooperation.

(2) Sale service

1. We will make a working video and take pictures to customers for confirmation before delivery (within 15 days after

receiving the total payment).

- Machine will be packed into the standard wooden cartons, suitable for vessel or air transport, and marked the universal

- Send customers commercial invoice, packing list, BL or AWB sheet, optional CO or FF or FTA or SASO for customer

(3) After-sale service

1.Warranty and Service included:

a. Hardware: one year warranty; b. Software: whole life on update for free.

c. Maintenance and technological support: whole life.

2. Training:

a. 3--4 days free training for the whole system in Seller's company.

b. If customer needs our technician give the training abroad, the customer need charge for the transportation and accommodation

fees of engineer;

Including: how to set up the equipment; how to debug the light route; how to use the software and operate the equipment;

how to replace the bad material and spare parts, etc; how to maintain the equipment; how to estimate and settle the problem,

and analysis the reason.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23