Pet Flakes Granules Making Machine Made in China

Taizhou Shangzheng Hydraulic Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. BDX Customized Customized Certification CE, ISO9001:2008, QS, UL, GMP Condition New Flake Size Around 12mm Capacity 80-500kg/H Can Add The Extra Hopper Yes for Masterbatch, CaCO3 etc Cooling Mathod for Barrel Water Cooling or Oil Cooling Pellet Size 1-2.5mm Diameter Power 110kw Around Can Equip with Crystallizer and Dryer Yes Gas Vent Natural Vent and Vacuum Vent IV Volume Around 8 for The Pellet Quality European Quality Transport Package Sea Worthy Packing Specification CE ISO Trademark BDX Origin Zhangjiagang Jiansgu China HS Code 84778000 Production Capacity 50 Sets/YearProduct Description

Pet Flakes Granules Making Machine Made in ChinaProduct Description:

Braces particle cutting machine is mainly used in PET, PVC and other high viscosity materials.

The machine can reduce less loss of the viscosity of the raw material. Compared to water-ring cutting, it is not easy to break the article or adhesion. The granules that the Braces particle cutting machine produce are much more uniform and beautiful.

1. Feeding Machine

This machine can be used with all kinds of extruders. It can carry plastic are cleaned into the hopper of Extrude. Automatic. It can save your labour, ande realize the effect of safety and reliability.

2. Extruder

This machine is used to extrude plastic cleaned by high temperature. The extrusion line can be consisted by such accessory machine: Main motor, the gear box, the barrel and screw, the dies, . Main Motor is mainly to supply the power. The Gear box transfers the motor to power. The distribution box enlarges the strength of the power and realizes uniformity. Double screws can make low viscosity index consume of raw material and improve production. It also has a Cooling tank making the heat of screw be appropriate.

3. Mould

We use plug board type to change nets and keep machine working. The mould is made by 40Cr nitridation. The pressure sensor prompts to change the nets. There also can install a hydraulic equipment to change the nets more quickly.

4. Water Channel

The water channel is 4 meters long. Make out article of cooling

5. Winds drying machine

Through the double channels strong wind dryer, force drying and cooling article material reach the fast speed effect of shaping up.

6. Pelletizer machine

It adopts grain design, accracy is high and can guarantee the rotatory precision and stationery of power, movements of cylinder are controlled by the solenoid valve, the automatic degree is highand the noise is low

Plastic extrusion line/plastic extruder line/extruder/plastic recycling and granulation line

Model | (Screw Diameter)mm | L/D | (Driving Motor)kw | (Screw Max Speed) rpm | (Output) kg/h |

| SHJ-65 | 65 | 36 or 40/1 | 55kw | 500/600 | 80-200 |

| SHJ-72 | 72 | 36 or 40/1 | 90kw | 500/600 | 150-350 |

| SHJ-90 | 90 | 36 or 40/1 | 250kw | 500/600 | 500-800 |

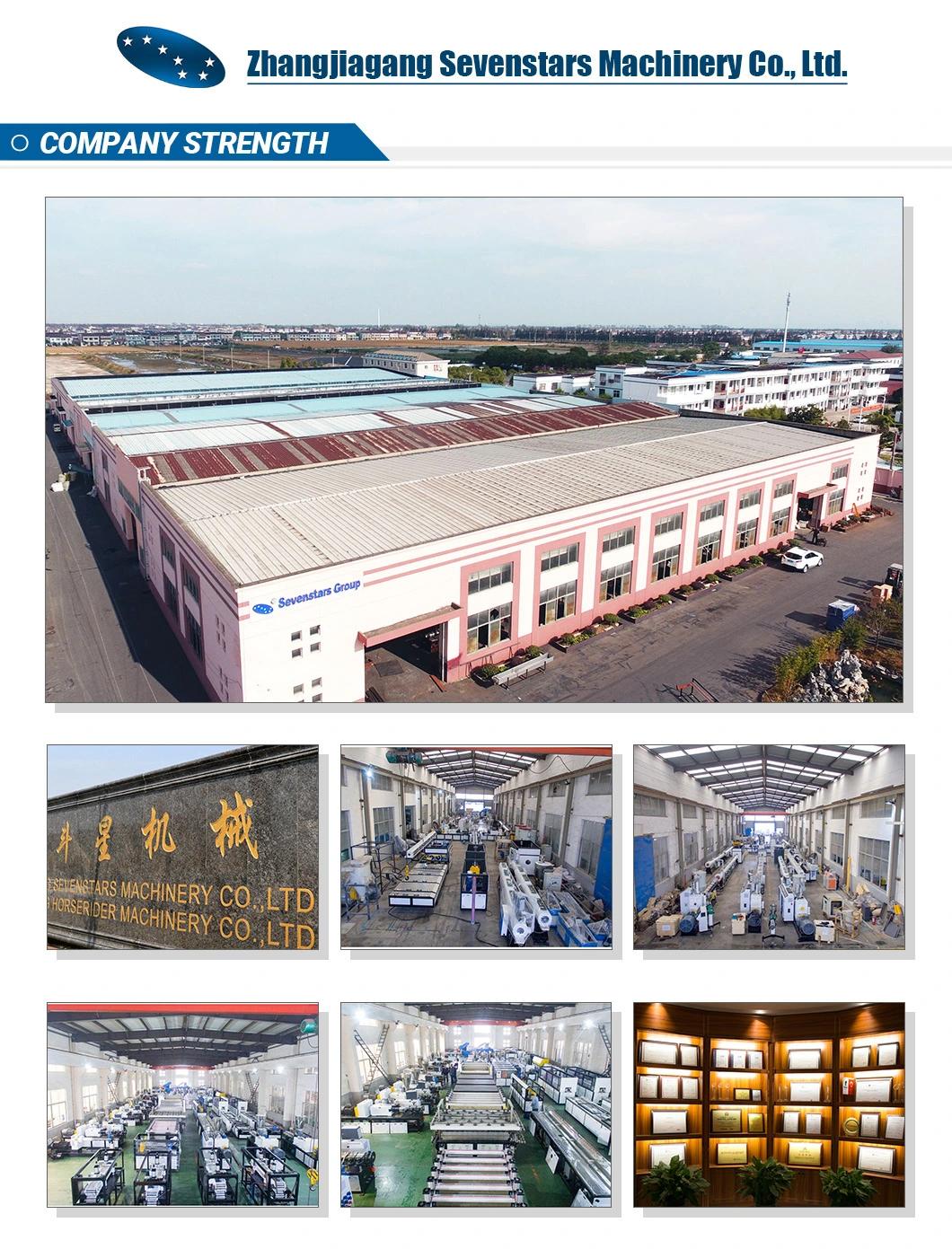

Zhangjiagang sevenstars is located in Zhangjiagang city, China, a beautiful and famous city for all kinds of plastic machine.

We have 17000 square meters land and new modern workshop, we mainly development, design, manufacture and marketing plastic pelletizing machine, plastic recycling machine, pet bottle recycling machine, PVC pipe making machine, PE pipe making machine, PVC foam board production line, plastic granulator, plastic shredder, plastic pulverizer, Plastic agglomerator, single shaft shredder, double shaft shredder, plastic crusher and so on. By the several years developing, we grown up to a middle scale company in China plastic industry.

As one of the reliable supplier in China, We have keeping improved our management and technology level. Up to now, we have earned good reputation in domestic and abroad market. And our products have been exported to many countries, like mexico, America, Argentina, Chile, Brazil, Russia and so on.

Quality and honest is our foundation, customer satisfactory is our job, to get "Win-Win" is our main targe. We always focus on improving our quality. And we have buit up a professional after-sale services team with rich-experienced in machine commissioning and installation. We believe our quality and service will bring success to each customer.

Welcome final users and distributors from all the world contact with us and create success.

With your support and our effort, we deeply believe that the tomorrow of sevenstar will be much better.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23