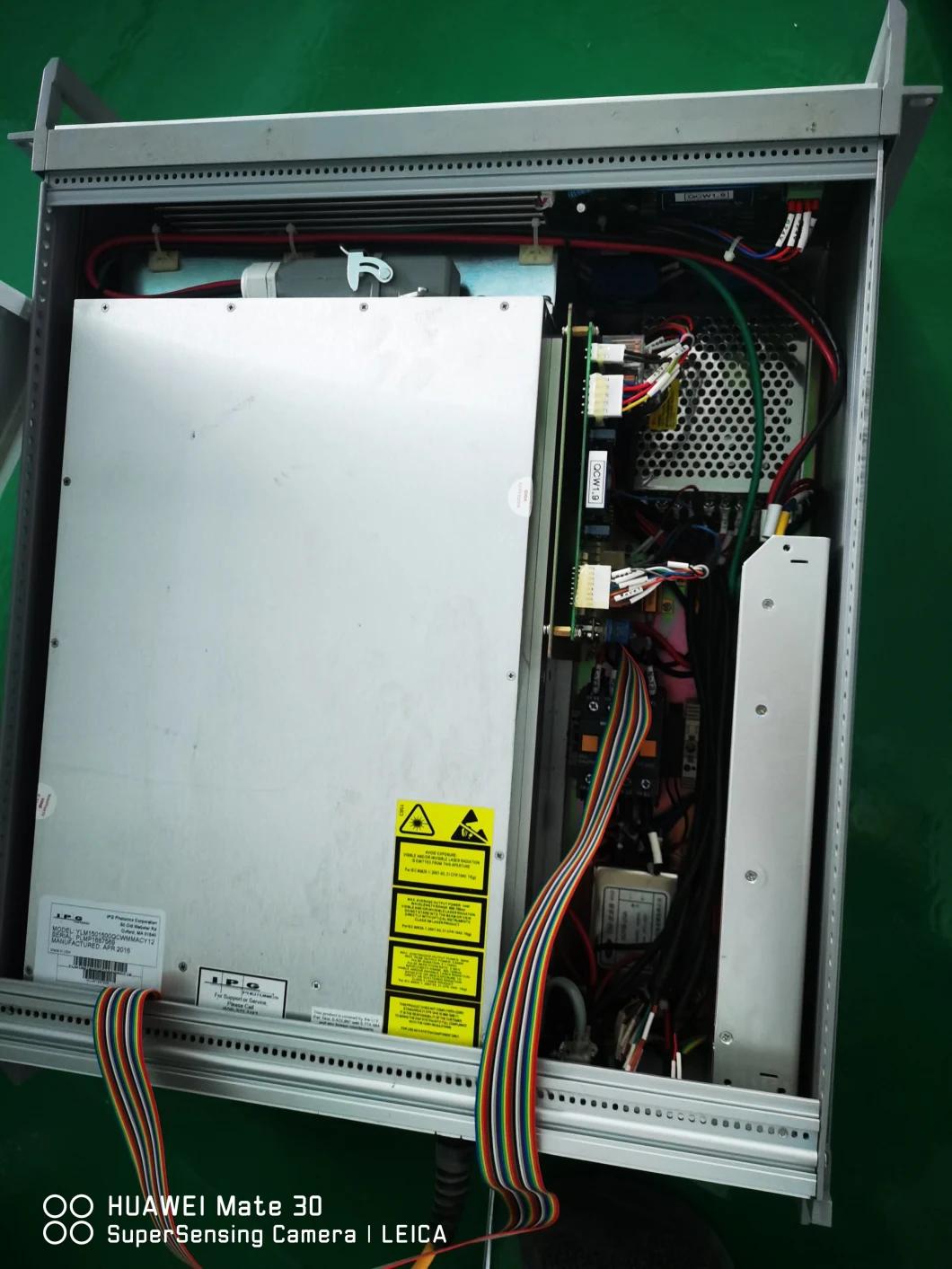

Ipg150qcw High Speed Splitting Laser Multimode Laser Fiber Laser

QINGDAO SURE CARE TRADING CO., LTD. / 2022-06-23

- After-sales Service:Online Technical Support

- Warranty:12

- Application:Biomedicine

- Technical Class:Continuous Wave Laser

- Control:Automatic

- Power Density:Deep Fusion Welding

=== Base Info ===

- Model NO.:YLM1501500QCWMMACY12

- Laser Classification:Optical Fiber Laser

- Type:Silicon Steel Sheet Laser Welding Machine

- Origin:Germany

- Production Capacity:10

=== Description ===

Basic Info.

Model NO. YLM1501500QCWMMACY12 Laser Classification Optical Fiber Laser Type Silicon Steel Sheet Laser Welding Machine Origin Germany Production Capacity 10Product Description

Fiber laser refers to a laser using rare earth element doped glass fiber as gain medium. Fiber laser can be developed on the basis of fiber amplifier: under the action of pump light, high power density is easy to form in the fiber, resulting in "particle number inversion" of laser energy level of laser working material. When a positive feedback loop is properly added (forming a resonant cavity) can form a laser oscillation output. Fiber lasers are widely used, including laser fiber communication, laser space long-distance communication, industrial shipbuilding, automobile manufacturing, laser engraving, laser marking, laser cutting, printing roller Metal and nonmetal drilling / cutting / welding (brazing, water quenching, cladding and deep welding),defense and security, medical instruments and equipment, large infrastructure, as the pump source of other lasers, etc.

Fiber lasers are widely used, including laser fiber communication, laser space long-distance communication, industrial shipbuilding, automobile manufacturing, laser engraving, laser marking, laser cutting, printing roller Metal and nonmetal drilling / cutting / welding (brazing, water quenching, cladding and deep welding),defense and security, medical instruments and equipment, large infrastructure, as the pump source of other lasers, etc.Fiber laser is a laser using rare earth doped glass fiber as gain medium. Fiber laser can be developed on the basis of fiber amplifier. Under the action of pump light, the formation success rate density in the optical fiber is easy to increase, resulting in the "particle number inversion" of the laser energy level of the laser working material. When a positive feedback loop (forming a resonant cavity) is properly added, the laser oscillation output can be formed

The generation of laser signal needs three basic conditions: particle number inversion, optical feedback and reaching the laser threshold. Therefore, the laser is composed of working material, pump source and resonator. The basic structure of the fiber laser is as follows: the gain fiber is the gain medium for generating photons; The function of pump light is to make the gain medium achieve particle number inversion as external energy, that is, pump source; The optical resonator is composed of two mirrors, which is used to make photons feedback and amplify in the working medium. The pump light is absorbed after entering the gain fiber, which reverses the number of energy level particles in the gain medium. When the gain in the resonant cavity is higher than the loss, a laser oscillation will be formed between the two mirrors to produce laser signal output

The generation of laser signal needs three basic conditions: particle number inversion, optical feedback and reaching the laser threshold. Therefore, the laser is composed of working material, pump source and resonator. The basic structure of the fiber laser is as follows: the gain fiber is the gain medium for generating photons; The function of pump light is to make the gain medium achieve particle number inversion as external energy, that is, pump source; The optical resonator is composed of two mirrors, which is used to make photons feedback and amplify in the working medium. The pump light is absorbed after entering the gain fiber, which reverses the number of energy level particles in the gain medium. When the gain in the resonant cavity is higher than the loss, a laser oscillation will be formed between the two mirrors to produce laser signal output1. Marking application

Pulsed fiber laser has become the only choice in high-speed and high-precision laser marking because of its excellent beam quality, reliability, the longest maintenance free time, the highest overall electro-optic conversion efficiency, pulse repetition frequency, the smallest volume, the simplest and most flexible use mode without water cooling, and the lowest operating cost.

A set of fiber laser marking system can be composed of one or two fiber lasers with power of 25W, one or two scanning heads used to guide light to the workpiece and an industrial computer controlling the scanning head. The efficiency of this design is more than 4 times higher than that of splitting beams from one 50W laser to two scanning heads. The maximum marking range of the system is 175mm * 295mm, the spot size is 35um, and the absolute positioning accuracy within the full marking range is + / - 100um. The focus spot at 100um working distance can be as small as 15um.

2. Application of material treatment

The material treatment of fiber laser is a heat treatment process based on the heating of the part where the material absorbs laser energy. The laser energy of about 1um wavelength is easily absorbed by metal, plastic and ceramic materials.

3. Application of material bending

Fiber laser forming or bending is a technology used to change the curvature of metal plate or hard ceramic. Concentrated heating and rapid self cooling cutting lead to plastic deformation in the laser heating area and permanently change the curvature of the target workpiece. It is found that the micro bending processed by laser has much higher precision than other methods. At the same time, it is an ideal method in microelectronic manufacturing.

4. Application of laser cutting

With the increasing power of fiber laser, fiber laser can be applied on a large scale in industrial cutting. For example, a fast chopping CW fiber laser is used to micro cut stainless steel arterial tubes. Due to its high beam quality, fiber laser can obtain very small focusing diameter and small slit width, which is refreshing the standard of medical device industry.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23