Jwell PP Meltblown Non Woven Fabric Extrusion Machine Line Making Face Jwell Brand 800mm ...

Jiangsu YiCheng Fluid Equipment Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. JWH800 JWH1600 JWH3200 Screw Single-Screw Engagement System Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Output (Kg/H) 20 - 200 Kg/H Certification CE & ISO Application Field Face Mask, Bag, Protective Clothes, etc Screw Material 38crmoala Key Selling Points High Productivity Transport Package Wooden Pallet Specification 15*8*6M Trademark JWELL Origin China Production Capacity 1000 Sets Per YearProduct Description

PP Meltblown Non woven Fabric Extrusion Line

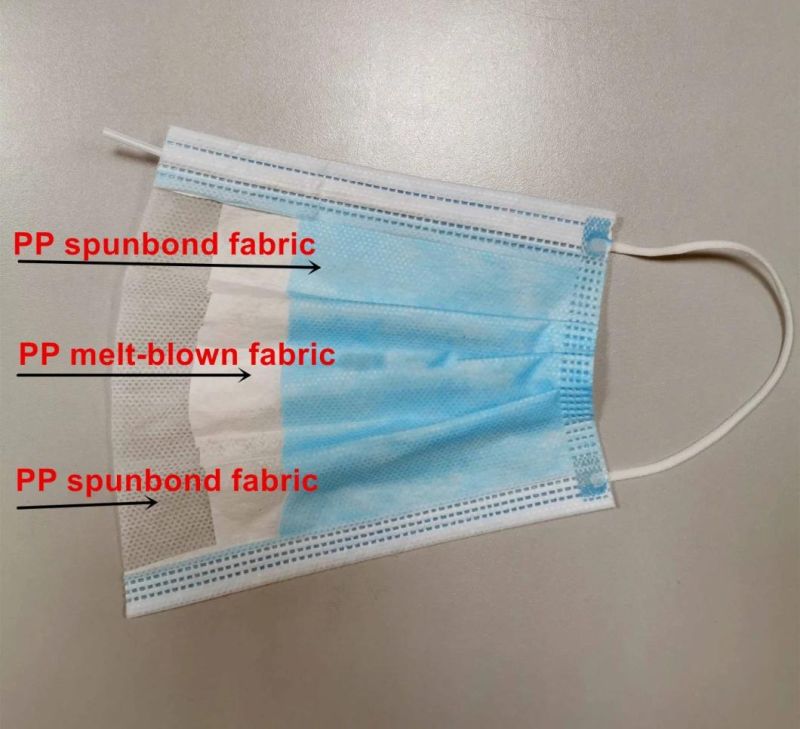

Nowadays, with the outbreak of various flu and viruses, masks have become a necessity of people's lives. Therefore, the rawmaterials of masks: non-woven fabrics and meltblown materials are now selling hot. Masks can protect people's health and cut off the transmission route to a certain extent.

The melt-blown fabric is widely applied tou filtration material, battery capboard etc, medical and health: a suit for surgery, a suit for selection, a cap, a mask, a massage cloth, an adhesive tape.

As we all know, melt-blown nonwoven fabric is the most core material of medical protective mask, and it is the key to fight disease war. CHINA JWELL can provide 800mm-3200mm width PP melt-blown nonwoven fabric production line rapidly through its own technical advantages for years. Adopt high quality core components, advanced technology production line, and high automation. At moment, more than 30 sets of high-performance and high-output production lines have been start production. The melt-blown die is the core component of the production line, fully supported by excellent partners represented by Zhejiang JCTIMES Die Co. etc., effectively shorten the production line delivery. At present, complete production line can be delivered to customers in 30-50 days delivery, which provides a strong guarantee for customers' rapid commissioning and disease prevention work.

Equipment Advantage

1.Professional screw design experience, good plastication, stable performance, suitable for high capacity extrusion.

2.High precision filter system and melt pump system, lively close-loop control extrusion pressure stably.

3.High precision extrusion die and spinnerets components, satisfy high quality product manufacture.

4.Professional high temperature resistant belt-type lapping system, optimized design of negative pressure system.

5.Fully automated online slitting, winding system, high-speed stable operation.

6.Adopt Siemens high-performance PLC integrated control system.

7.One-stop service, equipped with high-temperature furnace, static electret, vacuum cleaning and testing equipment.

Details Of Production Line:

Main Technical Parameters

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23